What Is a Stirrup? Definition and Fundamental Importance of Stirrups in Reinforced Concrete Structures

Stirrups form the foundation of the design and execution of any modern and safe reinforced concrete structure. A stirrup is not merely a bent piece of steel; rather, it is the very heart of a structure that resists destructive forces. Technically speaking, a stirrup is a type of transverse reinforcement that is placed vertically or horizontally around the longitudinal reinforcing bars of columns and beams. This vital component serves two fundamental purposes:

- It prevents the buckling of longitudinal compression reinforcement, which is one of the most critical risks in compression members such as columns.

- It provides resistance against shear forces and torsional forces generated by lateral actions such as earthquakes or wind.

Stirrups are defined as closed steel loops that are embedded within the concrete of structural members such as beams or columns.

What Is a Stirrup and Why Is It Important?

Stirrups are fabricated by bending reinforcing bars (rebars) at three or more points to form a closed loop. The shape of stirrups can be triangular, rectangular, square, circular, spiral, or diamond-shaped. In reinforced concrete structures, the most common types of stirrups used for square and rectangular columns are square, rectangular, or diamond-shaped stirrups.

Without the presence of stirrups, concrete can easily develop diagonal cracks, and the structure may suddenly and in a brittle manner collapse. Therefore, the question “what is a stirrup?” answers a fundamental need to create ductile behavior in structures. Ductility refers to the ability of a structure to undergo significant deformation prior to failure, allowing occupants sufficient time for safe evacuation.

A stirrup goes far beyond being a simple steel reinforcement and has become a key element in safeguarding human life and financial assets. Research conducted by Dr. George A. Rivera Cruz of the U.S. Army has shown that in low-seismic regions, concrete beams with stirrups spaced too far apart are prone to premature shear failure and are unable to develop catenary action.

Catenary Action is a mechanism in which, after the loss of a support (for example, due to an earthquake), the structural load is transferred through tensile forces in the beam’s longitudinal reinforcement, similar to a cable. This mechanism represents the last line of defense against progressive collapse. Therefore, proper stirrup design and precise execution directly contribute to saving lives and reducing financial losses during natural disasters. These findings led to revisions of design codes such as ACI 318, and today, even in low-seismic regions, the use of stirrups with closer spacing is mandatory.

Now you understand what a stirrup is.

Stirrups are used in many parts of a structure—from columns and beams in reinforced concrete frames to shear walls, bridges, foundations, and even tank supports. In columns, stirrups are typically placed at closer spacing near the top and bottom ends to prevent concrete cracking and reinforcement buckling in plastic hinge regions. In beams, the density of stirrups is higher near the supports and beam ends where shear forces are maximum, and it gradually decreases toward the midspan. This intelligent distribution prevents excessive steel consumption and optimizes costs.

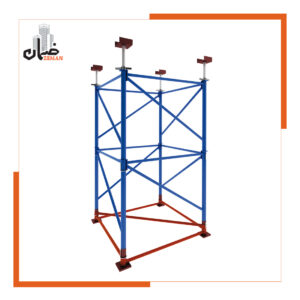

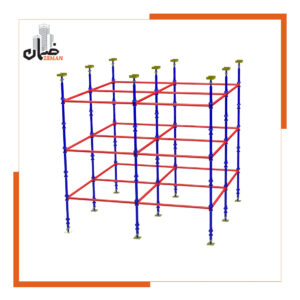

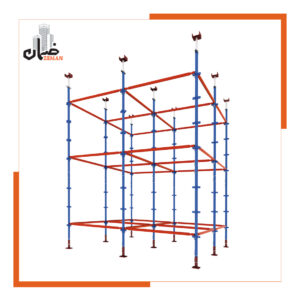

To accurately implement these designs, concrete formwork systems such as concrete wall formwork and circular column formwork are used to maintain the exact position of stirrups. In addition, in high-rise projects, suspended stirrups (such as those in tall column heads) must be stabilized using support systems like adjustable steel props or triangular scaffolding to prevent displacement.

This close relationship between reinforcement design and formwork and scaffolding systems highlights the complexity and coordination required in executing a construction project. Ultimately, the stirrup is a symbol of precise engineering and responsibility in the face of nature’s forces, transformed into a safe physical reality through global standards such as ACI 318.

Types of Stirrups

A stirrup is not a single, uniform concept; rather, it includes various types, each designed for specific loading conditions. Understanding these differences is critical for correct selection and safe execution. The two main types of stirrups are open stirrups and closed stirrups.

Open Stirrups

Open stirrups, typically U-shaped, have free ends and are mainly used to resist shear forces in reinforced concrete beams, especially in locations where torsional effects are negligible. This type of stirrup is placed on the tension side of the beam, where shear cracks are expected to form. However, the use of open stirrups is not recommended in seismic-resistant design and is considered unsuitable in many cases.

Closed Stirrups

(Also sometimes referred to as a “Hoop”) a closed stirrup is a complete and continuous loop that fully encloses the longitudinal reinforcing bars. This confinement provides significantly higher shear resistance and more effectively prevents the buckling of longitudinal reinforcement. Closed stirrups are mandatory in situations where a reinforced concrete beam must resist considerable torsional forces. Laboratory studies have shown that closed stirrups in all tested specimens were capable of sustaining shear forces and exhibited flexural failure, whereas open stirrups under similar conditions experienced shear failure. These findings clearly demonstrate the superior performance of closed stirrups.

Application of Stirrups in Construction

Stirrups are vital components of reinforced concrete structures and are used to resist shear, torsional, and bending forces.

The main applications of stirrups include:

In Beams

- Preventing diagonal cracks by resisting shear forces.

- When loads are applied, the bottom of the beam is subjected to tension while the top is under compression; stirrups transfer shear forces between these two zones and prevent crack formation.

In Columns

- Resisting lateral forces such as earthquakes or wind.

- Stirrups are installed at regular intervals along the height of the column to confine the concrete and enhance its strength and ductility.

In Slabs

- Ensuring uniform load distribution across the slab and preventing stress concentration.

- As a result, stirrups guarantee the strength, stability, and durability of concrete structures.

Types of Stirrups Used in Construction

1. Based on Geometric Shape

- Rectangular Stirrup: The most common type of stirrup used to resist shear forces in beams and columns.

- Square Stirrup: Similar to the rectangular type but square in shape; suitable for square columns.

- Circular or Round Stirrup: Used in circular columns to resist lateral forces.

- Triangular Stirrup: Used to enhance stability against diagonal stresses, particularly in cantilever structures such as retaining walls.

- Spiral Stirrup: Used in structures with spiral reinforcement to maintain bar spacing and prevent buckling.

2. Based on Configuration or Number of Legs

- Single-Leg Stirrup: Fabricated from a single U-shaped bent rebar; less common due to installation difficulty and limited lateral support.

- Double-Leg or Double Stirrup: The most common type in construction; consists of four legs and a fully closed loop, providing high shear resistance.

- Four-Leg Stirrup: Rectangular in shape with eight closed legs, used in structures requiring heavy reinforcement.

- Six-Leg Stirrup: Hexagonal in shape, designed for large columns and members requiring additional reinforcement.

The use of professional equipment such as modular metal formwork and modular formwork systems makes the proper installation of these stirrups possible.

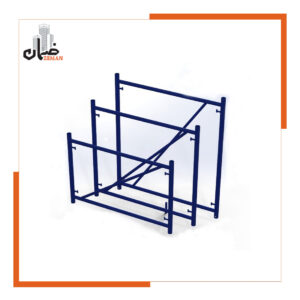

These systems increase execution accuracy and speed, ensuring that stirrups are positioned exactly as designed. In addition, for safe access to stirrup installation locations at height, various scaffolding systems such as cup-lock scaffolding, hammer scaffolding, and H-frame scaffolding are used.

The correct selection of this equipment directly affects the quality and safety of stirrup installation.

Proper Execution of Stirrups – From Placement to Connections and Protection

| Type of Stirrup | Characteristics | Seismic Application | Reference Code |

|---|---|---|---|

| Open Stirrups | Placed within beams | Not fully enclosed | Not permitted in seismic regions | ACI 318-19 |

| Closed Stirrups | Provided with 90° or 135° hooks | Mandatory in seismic regions | ACI 318-19 |

| Multi-Leg Stirrups | Used for larger beam and column dimensions | Require special design | ACI 318-19 |

| Single-Leg Stirrups | Used to tie two reinforcing bars | Require special design | ACI 318-19 |

| Type of Stirrup | Characteristics | Application and Design Considerations |

| Open Stirrups | U-shaped and placed on the tension side of beams | Not used in seismic regions |

| Closed Stirrups | Provided with 90° or 135° hooks | Mandatory in seismic regions |

| Multi-Leg Stirrups | Used for larger column and beam dimensions | Require special structural design |

| Single-Leg Stirrups | Used to tie two reinforcing bars together | Require special structural design |

Conclusion

What is a stirrup? Stirrups are among the most important elements in reinforced concrete structures, as they significantly enhance resistance against shear and torsional forces. These components function as shear reinforcement in beams and columns. Closed stirrups are mandatory in seismic regions and in plastic hinge zones.

In summary, a stirrup plays a role far beyond that of a simple reinforcing bar and is recognized as the hidden backbone of concrete structures. By preventing the buckling of longitudinal reinforcement and shear failure, this steel component ensures the stability and ductility of the structure. Selecting the appropriate type of stirrup (open, closed, or multi-leg), adhering to standard spacing requirements in accordance with codes such as

ACI 318,

and executing precise on-site installation with the support of safe formwork and scaffolding systems are key factors in constructing structures resistant to earthquakes and lateral forces. Ultimately, a stirrup is not merely an execution detail; it is a guarantor of safety, durability, and long-term performance of reinforced concrete structures against natural disasters and the effects of time.