What Is Scaffolding? The Ultimate Guide to Load Calculations, Standards, and Technical Differences (Triangular and Hammer-Lock)

What Is Scaffolding? From the General Concept to the Specialized Modular Application

In English, the word “Scaffold” broadly means “scaffolding” and covers all temporary structures used for access or support at height—from traditional tube-and-coupler scaffolds to modular types.

However, in Iran’s construction industry and engineering terminology, the word “Scaffold” is used specifically to refer to modular scaffolding systems. These systems (including triangular and cuplock/hammer-lock types) are the new, engineered generation of scaffolds with prefabricated components, quick connectors, and significantly higher load-bearing capacities than traditional (tube-and-coupler) scaffolding.

Key point: When specialists in Iran talk about “scaffold,” they mean a load-bearing, safe temporary structure with a defined engineered configuration—not merely a worker access structure. This semantic distinction is central to Zeman’s technical focus on ensuring modular safety and quality.

Foundational Definitions and Competitive Advantage Analysis of Modular Scaffolding

1. Comprehensive Definition of Scaffolding and Its Role in Building Engineering

Modular prefabricated scaffolding is a temporary structural system with two vital roles in civil projects: providing safe access for personnel and materials at height, and—more importantly—providing load-bearing support (shoring/formwork support) to carry the weight of primary structures such as concrete slabs, beams, and arches during construction and curing.

Unlike traditional scaffolds (tube-and-coupler), which are mainly access tools and whose stability depends on manual knotting and clamps, modular scaffolding consists of standardized, all-metal components (frames, standards, and braces) that ensure very high strength and load capacity through quick connections. This temporary structure must be subjected to precise structural calculations.

2. Technical Advantages Over Traditional Scaffolding

Choosing modular scaffolding is an engineering decision aimed at optimizing project time, cost, and risk. Advantages over legacy tube systems are as follows:

| Technical Feature | Deep Dive Explanation | Direct Impact on Project and Contractor |

|---|---|---|

| Assembly and Disassembly Speed | Male–female joints (triangular) or hammer couplers (hammer-lock) eliminate the need for clamp fastening. Two trained workers can install up to 1,000 frames per day. | At least 30% to 50% reduction in scaffolding time, translating into savings on ongoing project costs. |

| Geometric Accuracy and Stability | Fixed, standardized frame dimensions ensure plumb and square erection. Adjusting screws enable millimetric leveling. | Enhanced safety during heavy-volume concreting and assured geometric quality of the primary structure. |

| Load Capacity | The triangular (Omega) design and the modularity of hammer-lock systems transfer loads directly and in a standardized manner to the ground. | The load-bearing capacity of a standard scaffolding tower can exceed 14 tons, sufficient for the heaviest slabs. |

| Required Workforce | Ease of assembly eliminates the need for highly skilled workers with years of traditional lashing experience. | Reduced human error and less dependence on a limited pool of specialist scaffolders. |

What Do Experts Say About Zeman Modular Scaffolding?

Specialized Types of Modular Scaffolding and Technical Design Details (Components and Materials)

Comparison of Modular Scaffolding Types: Triangular vs. Hammer-Lock

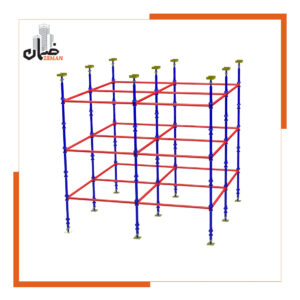

Triangular Scaffolding (Triangle/Omega Scaffolding) — The King of Shoring

Known for triangular Omega (Ω)-shaped frames, this is among the most robust modular scaffolding types. Triangular scaffolding is specifically designed to withstand concentrated, heavy vertical loads in shoring systems.

- Structure and Connection: Frames are produced in standard heights (such as 100, 75, and 50 cm) with a fixed width of 120 cm and quickly stacked via male–female (bush and pin) connections.

- Specialized Application: Shoring for tall concrete slabs, bridges, prestressed slabs, and facilities requiring sturdy, adjustable-height supports.

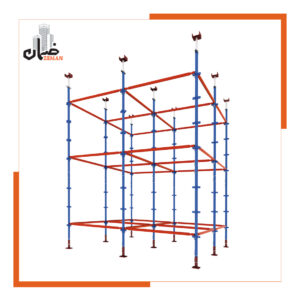

Hammer-Lock Scaffolding (Cuplock/Hammer-lock) — Flexibility at Height

Hammer-lock scaffolding consists of vertical standards and horizontal ledgers with a cup-shaped coupler connection mechanism.

- Structure and Connection: Ledgers have wedges seated in the lower cup of the coupler; a hammer blow drives the upper cup downward, creating a very strong and quick connection. Each coupler can support four ledgers in different directions.

- Specialized Application: Owing to high flexibility and rotatable bracing, this system suits façade works, irregular roofs, curved surfaces, and building industrial and refinery platforms.

Introduction to Cuplock Scaffolding — Modular Flexibility and Speed

Cuplock Scaffolding — A Flexible Modular System and a Flagship of Zeman

Alongside triangular scaffolding—the king of heavy shoring—cuplock (hammer-lock) is recognized as the most widely used multi-purpose modular scaffolding system. In Iran’s industry, it is also known as “cup” and “star” scaffolding. Thanks to its unique connection mechanism, it delivers exceptional speed and flexibility at height.

Analysis of the Cup-lock Mechanism and Its Technical Advantage

The name “cuplock” is derived from “cup-lock,” the core mechanism behind the efficiency of cuplock scaffolding:

- Vertical Standards (Uprights): These vertical tubes have nodal connection points (cups) at defined intervals (typically 50 cm), consisting of a lower (fixed) cup and an upper (movable) cup.

- Horizontal Ledgers: Ledgers, which provide lateral stability and form work platforms, have wedges at both ends.

- Locking: The ledger wedges sit in the lower cup. A simple hammer blow drives the upper cup downward, fully and safely locking the ledgers.

This rapid lock–unlock mechanism, and the lack of separate clamps, is why the system is also known as “hammer-lock.”

Multi-Directional Capability

The most important technical advantage of cuplock scaffolding is the high connection capacity at each node. Each cup node can simultaneously anchor four ledgers in different directions. This enables scaffold structures on multi-faceted and non-rectangular plans.

Technical Features — Expert Description and Practical Advantages of Cuplock Scaffolding

| Cuplock Technical Feature | Specialized Technical Description | Practical Advantage |

| Node Connection Capacity | Each node (cup) can connect up to four ledgers simultaneously. | High flexibility for circular structures and irregular façades. |

| Assembly Method | Hammer-driven cup connection, no clamps or wrenches required. | Faster assembly than triangular scaffolding at great heights. |

| Multi-Purpose Use | Suitable for access and (medium) shoring. | Dual-use in industrial projects, warehouses, and building façades. |

Specialized Applications of Cuplock Scaffolding

Cuplock scaffolding by Zeman, thanks to tube strength (ST37 steel) and precise coupler manufacturing, is ideal for a wide range of projects:

- Tall-building façade works: Easy to create working platforms on each floor with high assembly speed.

- Refineries and power plants: For maintenance in complex facilities where access to various structural points is essential.

- Supporting waffle and U-boot slab formwork: For light-to-medium shoring where rapid erection and striking are critical.

Zeman, by manufacturing and directly supplying cuplock scaffolds with precise weight and dimensional standards, ensures safety and efficiency in your projects.

Critical Components and Material Requirements (ST37 Standard)

Final quality and safety of scaffolding directly depend on components and base materials. Zeman guarantees that all products are manufactured from structural steel grade ST37 with standard thicknesses:

- Vertical standards/frames: These must be produced from standard tubes with 48.3 mm outside diameter and minimum wall thickness of 2.5 to 4 mm (per ISIRI 3454). Thinner walls severely compromise safety.

- Adjusting screw (Adjusting Jack): This component provides precise load leveling. The effective thread length (the travel the screw can extend) is critical and must not be overextended to avoid increasing the risk of buckling.

- Base plate (Sole Plate): Distributes the point load from the tube to a wider surface (ground or sole boards). Plate thickness must not be less than 5 mm, and its area must not be less than 175 cm².

- Cross/Horizontal bracing members: Their primary function is lateral stability and preventing sway and tilt at height.

Load-Bearing Calculations and the Concept of Safe Working Load (SWL)

A supplier’s technical competence is reflected in the ability to provide accurate load-bearing data. Scaffolding load capacity must be calculated based on three main load types:

- Dead Load (DL): Self-weight of scaffolding components, formwork, and secondary beams.

- Live Load (LL / UDL): In shoring, this includes the weight of freshly cast concrete (the dominant load), plus workers, tools, and vibrators.

- Environmental Loads: Such as wind acting on lateral surfaces.

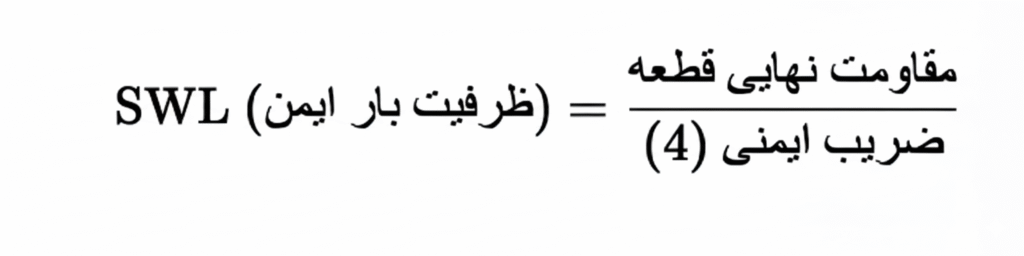

The Golden Rule of Safety Factor (4:1)

Under international and national requirements, all scaffolding components must withstand at least four times (4:1) the maximum expected load. This factor serves as a safety margin against material defects, erection errors, or sudden dynamic loads.

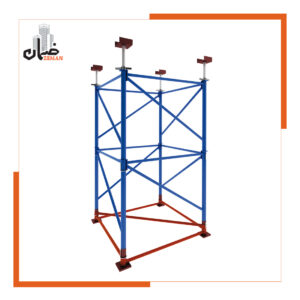

Strategies to Increase Load Capacity

For projects with very high loads:

- Reduce grid spacing: Reducing center-to-center spacing of scaffolding towers from

150×150 cm

to

100×100 cm

increases capacity exponentially. - Use twin systems: In some cases, placing two scaffolding towers side by side doubles robustness and safety against dynamic loads.

Compliance with National Standards and Ministry of Labor Regulations

Technical credibility of Zeman products is ensured by full compliance with national laws:

ISIRI 3454 Standard:

Specifications for tubes, especially the exact 48.3 mm outside diameter and minimum wall thickness.

Work at Height Safety Regulations (Ministry of Labor):

- Anchorage: Emphasis on tying the scaffold to the main building at specified heights using right-angle or special clamps.

- Site preparation (Article 83): Emphasis on inspection and leveling of the foundation before installation, and using sole boards on weak ground.

To download the Ministry of Labor’s executive safety regulations for work at height, click here.

Why Is Zeman Modular Scaffolding the Final Choice of Engineers?

Optimizing Risk and Return (ROI) in Civil Projects

In the fast-paced construction world, success depends not only on the quality of the final structure but also on smart management of risk, time, and cost during execution. Modular scaffolding, beyond a temporary tool, is an investment-oriented engineering solution balancing safety and performance.

1. Safety Assurance: Investing in the Workforce

The most prominent advantage of modular systems is the safety factor. This is not just a technical number; it is an ethical and legal commitment that brings the risk of catastrophic collapses from heavy concreting near zero. Compared to traditional scaffolding—whose stability depends on worker skill and cast-iron clamp quality—Zeman’s triangular and cuplock systems, with engineered connections and ST37 steel tubes, offer measurable, dependable structural stability. Full compliance with ISIRI 3454 for tube production with standard thicknesses is the foundation of this safety.

2. Cutting the Hidden Cost of Time

Time is money in construction. Cuplock (cup) and triangular systems, thanks to quick connection mechanisms (male–female or hammer-lock), dramatically reduce assembly and striking times. The ability to install over 1,000 frames per day means:

- Lower daily rental costs: Scaffolds leave the site sooner.

- Faster concreting cycles: The project stays on schedule and delay penalties are reduced.

- Reduced need for highly specialized labor: Costs for traditional master scaffolders are eliminated.

3. Flexibility for Any Structural Challenge

With four-ledger connectivity at each cup node, cuplock provides the ultimate solution for complex geometries (circular façades, refineries, or uneven roofs). Conversely, triangular scaffolding, with heavy load capacity, is essential for thick slabs and large bridges. By offering both systems, Zeman serves as your specialist advisor for selecting the optimal structure based on drawings and load demands.

After reviewing scaffolding standards and load calculations, the next step is selecting and pricing and purchasing scaffolding suited to your project’s needs.

Final Conclusion

Choosing Zeman modular scaffolding is not merely purchasing equipment; it is buying confidence and process optimization. With a focus on material quality, 100% regulatory compliance, and proven advantages in speed and stability, Zeman is your reliable technical partner for executing safe, precise, and economical projects.

Specialized Scaffolding FAQs

These questions are designed to cover the widest range of specialized searches and achieve Rich Snippet placement in Google results:

1. What is the principal difference between triangular and cuplock scaffolding?

Answer: The main criteria are vertical load capacity and connection type. Triangular scaffolding with rigid frames has much higher vertical capacity and is used for heavy shoring. Cuplock (cup) with hammer-driven, multi-faceted nodes delivers greater plan flexibility and higher speed for façade work and access.

2. Why must the scaffolding tube be 48.3 mm?

Answer: The 48.3 mm outside diameter (approximately 2 inches) is a global standard and mandated by ISIRI 3454. It provides an optimal balance between the required strength for load-bearing and a manageable weight for handling. All standard clamps and couplers are designed around this diameter.

3. What is buckling in scaffolding and how can we prevent it?

Answer: Buckling is the sudden bending or deformation of vertical tubes under excessive compressive load and is a leading cause of scaffold failure. To prevent buckling:

- Use tubes with sufficient wall thickness (> 2.5 mm).

- Do not overextend adjusting screws (jacks).

- Install lateral bracing at standard intervals.

4. How exactly is SWL (Safe Working Load) calculated?

Answer: SWL is obtained by dividing the ultimate load capacity of each component (determined by laboratory testing) by the safety factor (which is 4). This ensures that the permissible load is four times lower than the onset of potential failure.

5. How thick should the base plate be?

Answer: Per safety regulations, base plates must be at least 5 mm thick with a minimum area of 175 cm² to distribute point loads and prevent standards from punching into the ground.

6. How important is galvanization in scaffolding?

Answer: Galvanization (zinc coating) does not affect mechanical strength (load capacity) but significantly increases service life in humid or corrosive environments (e.g., coastal projects) and prevents premature rusting.

7. What is ST37 steel grade?

Answer: ST37 is one of the most common structural steel grades with a suitable minimum yield strength for temporary load-bearing structures. Zeman uses only this grade or higher to ensure quality.

8. Can cuplock scaffolding be used for very high elevations (e.g., 70 meters)?

Answer: Yes. Cuplock is suitable for high-elevation access due to quick assembly and stable connections, provided that lateral anchorage to the main structure is carefully executed at shorter intervals to ensure wind stability.

9. At what spacing should lateral anchorage be installed?

Answer: Lateral anchorage should be tied to the main structure at specified vertical and horizontal intervals—typically less than 3 meters. For very tall scaffolds or windy regions, the designer must reduce these spacings.

10. Do we need highly skilled traditional scaffolders to use modular systems?

Answer: No. A key advantage of modular (triangular and cuplock) systems is that simple lock-and-cup mechanisms eliminate complex traditional lashing. Workers only need to be familiar with basic assembly and safety principles, reducing costs and dependence on niche specialist labor.