Waterproof Tie Rod

The Water Stop Tie Rod is one of the most critical components in concrete formwork systems, particularly for concrete structures that are exposed to water, such as reservoirs, swimming pools, dams, and underground foundations.

What Is a Water Stop Tie Rod?

A water stop tie rod is a component installed between two threaded tie rods and is designed to prevent water or moisture penetration through the residual formwork holes left after concrete casting.

Main Components of a Water Stop Tie Rod

- Main Body (Sleeve or Core):

Typically manufactured from cast iron, steel, or reinforced plastic. Both ends are threaded and connected to the tie rods. - Central Sealing Ring (Water Stop Ring):

Made of rubber or PVC and positioned at the center of the tie rod. Its function is to permanently block water passage through the joint between the two tie rod sections. - End Tie Rods (Half Rods):

After concrete placement, the outer ends of the tie rods are cut and removed, while the water stop tie rod remains embedded inside the concrete.

Types of Water Stop Tie Rods

Water stop tie rods are classified into several main categories based on material, operating mechanism, and application. The most common types are outlined below:

- Metal Water Stop Tie Rod

Material: Cast iron or electroplated steel.

Features: Exceptionally resistant to concrete pressure and water penetration. Equipped with a central rubber or PVC sealing washer for permanent waterproofing. Ideal for large hydraulic structures such as dams, wastewater treatment plants, tunnels, swimming pools, and underground foundations. - Plastic Water Stop Tie Rod

Material: Reinforced ABS or PVC.

Features: Lightweight and more economical than metal types. Easier installation and suitable for lighter structures or temporary projects. Provides moderate waterproofing performance, appropriate for low to medium pressure conditions. - Mechanical Threaded Water Stop Tie Rod (Three‑Piece System)

Structure: Two threaded half tie rods plus a central internally threaded water stop sleeve.

Features: Allows separation of the half tie rods after concreting. Precise length adjustment is possible. High durability with the ability to reuse the external tie rods. - Single‑Use Water Stop Tie Rod

Material: Typically plastic.

Features: Remains permanently within the concrete after casting. The external tie rods cannot be recovered or reused. Suitable for low‑cost or fast‑track construction projects. - Reusable Water Stop Tie Rod System

Configuration: The central water stop element remains embedded in the concrete, while the outer tie rods are removed and reused after execution.

Features: Usually manufactured from metal or composite materials. Cost‑effective for repetitive and large‑scale projects due to reusability.

Advantages:

Prevents water leakage through tie rod penetration points. Capable of resisting high concrete pressure in cast‑in‑place walls. Allows easy removal of external tie rods after concreting while maintaining permanent waterproofing.

Waterproof Tie Rod

In the complex world of civil engineering, water penetration into concrete structures has long been a persistent and costly challenge. This phenomenon, particularly in structures that are in direct contact with water—such as tanks, pools, dams, and water conveyance channels—can lead to structural erosion, reinforcement corrosion, and a significant reduction in the service life of a project. Complete and flawless waterproofing is not an option, but an engineering necessity. In this context, the “waterproof tie rod (water stop bolt)” plays a dual and indispensable role as a critical engineered component: it not only maintains the precise spacing between concrete formworks during casting, but also serves as a permanent, impermeable barrier against water infiltration.

Zeman Company, as one of the pioneers in the production of concrete formwork systems in the Middle East, leverages up-to-date technical expertise alongside state-of-the-art machinery and industrial robotics to deliver comprehensive solutions in this field. With an annual production capacity exceeding 16,000 tons of various steel formworks and accessories, Zeman is a reliable partner for the successful execution of civil projects of any scale. This technical report provides an in-depth review of waterproof tie rods, their types, applications, and selection criteria, assisting engineers and project contractors in achieving durable and fully watertight structures.

What Is a Waterproof Tie Rod and How Does It Prevent Water Leakage?

To understand the engineering performance of a waterproof tie rod, one must first analyze the main challenge in concrete wall formwork. During wall concreting, fully threaded tie rods are used to resist the massive hydrostatic pressure of fresh concrete and to prevent formwork separation.

These bolts pass through the form panels and hold the two sides together. After the concrete sets and the formwork is removed, these temporary bolts are extracted, leaving a through-hole in the concrete. In conventional structures such as residential buildings, these holes are easily filled with mortar and typically pose no major issue. However, in hydraulic structures that must resist water penetration, these same holes become critical weak points and primary paths for water leakage.

The waterproof tie rod has been designed as a smart, integrated solution to this problem. Instead of temporary bolts, this component is positioned at the center of the wall thickness between the two form panels and, after concrete placement, remains permanently embedded within the concrete. Its unique structure—particularly the circular flange found in cast iron and steel models—extends and blocks the water path, effectively preventing any form of leakage.

The true value of the waterproof tie rod lies in its dual and simultaneous function. This component is not merely a connector or a water stop; rather, it is an engineered system that performs three critical tasks at once:

- Clamping opposing formworks together: Ensures the stability of the formwork system.

- Maintaining a fixed distance between formworks: Guarantees precise and uniform concrete wall thickness.

- Permanent sealing of the bolt passage: Eliminates the need for any secondary waterproofing operations.

This integrated approach optimizes the construction process. By eliminating time-consuming and error-prone steps such as bolt removal, hole cleaning, and injection of waterproofing materials, the waterproof tie rod becomes a process-optimization tool that significantly enhances both structural integrity and overall project productivity.

Comprehensive Guide to Types of Waterproof Tie Rods (Technical and Comparative Analysis)

Waterproof tie rods are categorized into three main types based on material, manufacturing process, and structural configuration. Selecting the appropriate type depends on technical requirements, budget considerations, and the specific conditions of each project.

Cast Iron Waterproof Tie Rod: The Standard of Strength and Durability

The cast iron tie rod is the most widely used and common type and is frequently employed in sensitive projects due to its superior mechanical properties.

- Material and Manufacturing Process: This component is produced from ductile (nodular) cast iron using a single-piece casting method. This process ensures that the final product is free of seams, welds, or weak points, providing maximum resistance to hydrostatic and mechanical pressures.

- Technical Specifications: These tie rods are typically manufactured in standard dimensions: an overall length of 12 cm and a central circular water-stop flange with a diameter of 7–8 cm. Their approximate weight of 550 grams reflects the high density and quality of the raw material.

- Performance and Installation: During formwork installation, the component is placed at the center of the wall thickness. Two external bolts (usually fitted with plastic sleeves to prevent bonding with concrete) are connected from both sides to the internal threads of the tie rod. After concreting and form removal, the external bolts are removed, while the cast iron tie rod remains permanently embedded in the concrete.

- Advantages and Applications: Extremely high compressive strength, fast and easy installation, and cost-effectiveness relative to its outstanding performance are among its key advantages. Thanks to the high chemical resistance of cast iron, this model is the optimal choice for structures exposed to acidic or corrosive environments. Consequently, it is the first choice of engineers for dams, water and wastewater tanks, and large swimming pools.

Plastic (PVC) Waterproof Tie Rod: An Economical and Flexible Choice

Unlike the cast iron type, this model is not a single component but a modular system composed of several parts, offering high flexibility.

System Components:

- Ribbed PVC Pipe: The main body of the system, made of durable PVC, through which the bolt passes. Its key feature is adjustable length according to wall thickness.

- Connector (Spool): Connects the ribbed pipe to the conical piece. Its surface ribs create strong mechanical interlock with concrete, preventing water penetration at the interface.

- Cones: Located at both ends of the system and in contact with the inner surface of the formwork. After concreting and form removal, these cones can be easily extracted from the concrete.

- Stoppers: These components complete the final stage of waterproofing. After cone removal, a U-type stopper (plain, without flange) is pressed into the center of the ribbed pipe to create an internal barrier. Then, two T-type stoppers (flanged) are installed from both sides to fully seal the external surface.

Advantages: The primary advantage of this system is its very low cost, which can reduce waterproofing expenses by up to five times. Light weight, ease of transport and installation, high flexibility in length adjustment, and chemical inertness to concrete are additional benefits.

Applications: This model is ideal for projects where budget optimization is critical, such as private swimming pools and small to medium-sized concrete tanks.

| Component | Function | Quantity per System |

|---|---|---|

| PVC Ribbed Pipe | Spacing and bolt passage; variable length | 1 |

| Connector (Spool) | Connects pipe to cone; concrete interlock | 2 |

| Cone | Form contact and cavity creation | 2 |

| U Stopper (Plain) | Internal pipe sealing | 1 |

| T Stopper (Flanged) | Final external surface sealing | 2 |

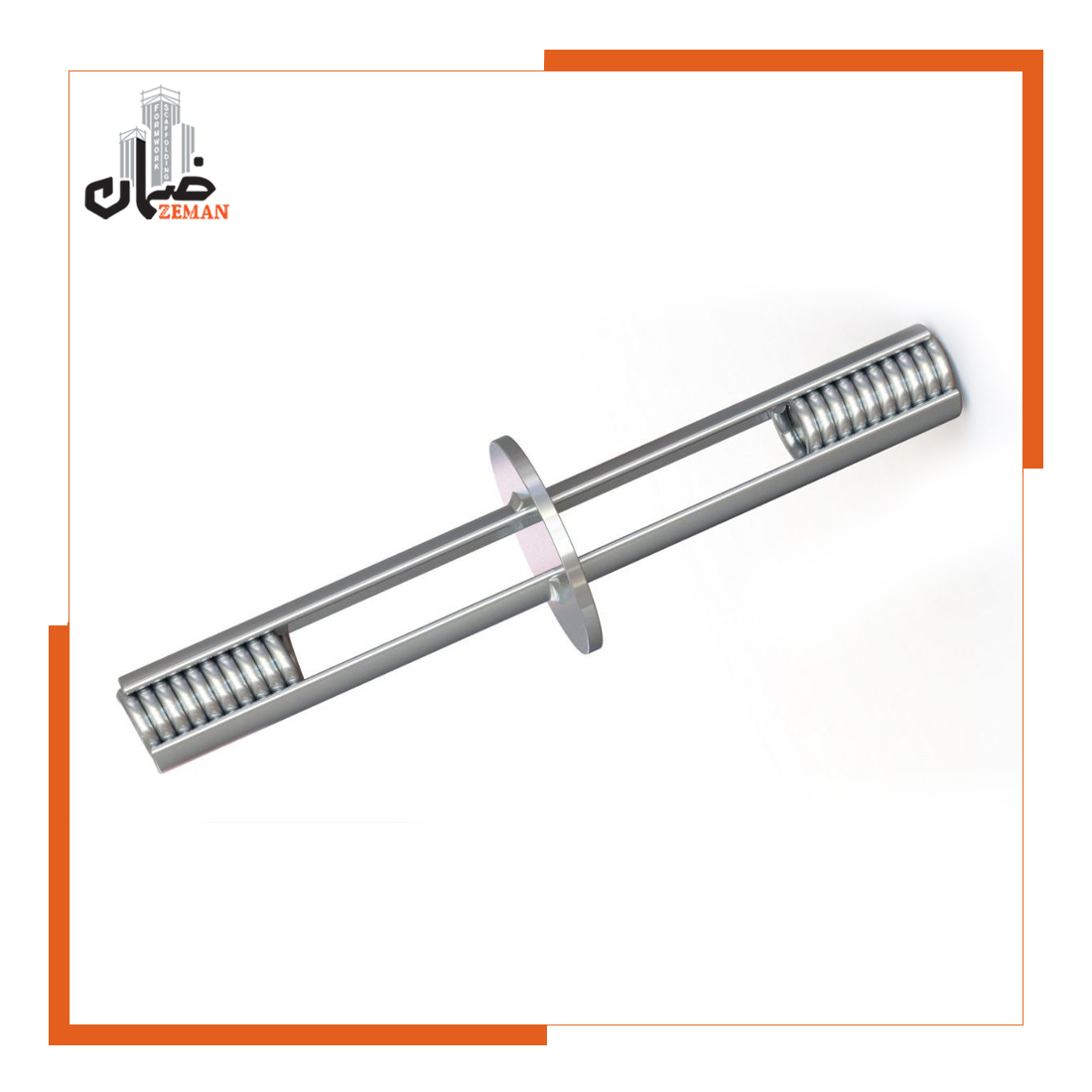

Metal (Spring-Type) Waterproof Tie Rod: Engineered for Special Projects

This type is designed for projects requiring adaptation to non-standard wall thicknesses and high tensile strength.

- Structure and Types: The main body consists of a metal element (flat bar for lengths under 50 cm and rebar for greater lengths), with two spring nuts welded at both ends. These nuts are manufactured in fine-thread and coarse-thread types to match various formwork bolts.

- Technical Specifications: Similar to the cast iron model, this type features a central circular steel water-stop plate, typically 3 mm thick and 7 cm in diameter. The spring length (5–10 cm) and overall body length are fully customizable according to wall thickness and concrete pressure.

- Key Measurement Note: A critical technical consideration is required when ordering this product. The length of the metal tie rod must be ordered 6 cm shorter than the final wall thickness, due to the addition of two plastic cones (3 cm each) at both ends during installation.

- Advantages: The primary advantage of this model is precise custom length manufacturing for non-standard wall thicknesses. It also offers very high tensile strength and exceptional stability within the formwork system.

- Disadvantages: Its cost is generally higher than that of the cast iron model, and its manufacturing process is more time-consuming and complex due to welding requirements.

Key Applications of Waterproof Tie Rods in the Construction Industry

The use of waterproof tie rods is essential in any structure where preventing water penetration is a priority. Key applications include:

- Hydraulic and Water Structures: This is the primary application field. Structures such as dams, potable water and wastewater storage tanks, water conveyance channels, cooling towers, and treatment plants all require complete waterproofing for long-term performance.

- Residential and Commercial Projects: In swimming pools, jacuzzis, emergency water tanks, retaining walls, and basement walls exposed to groundwater pressure, the use of this component prevents future moisture and dampness issues.

- Infrastructure Projects: In urban and intercity tunnels, excavation support structures, and shear walls requiring waterproofing due to their location, waterproof tie rods play a critical role.

How to Choose the Best Waterproof Tie Rod for Your Project?

Selecting the appropriate tie rod is an engineering decision requiring a balance among three key factors: cost, performance, and flexibility. An incorrect choice can lead to increased costs or reduced waterproofing efficiency. The following framework helps engineers and project managers make the optimal decision:

- Define Project Requirements: The first and most critical step is determining whether the structure truly requires waterproofing. For standard shear walls in residential buildings, ordinary bolts and hole filling may suffice, but this approach is unacceptable for water tanks.

- Budget Analysis: When budget constraints are decisive, plastic tie rods are the most economical option due to their very low cost.

- Wall Thickness Review: For standard wall thicknesses, cast iron and plastic models are suitable. For custom or non-standard thicknesses, the metal (spring-type) tie rod is the only viable option due to its adjustable length.

- Structural Pressure Evaluation: In projects with high concrete pouring heights and significant hydrostatic pressure (such as tall dam walls), cast iron and metal models provide greater reliability due to superior mechanical strength.

- Environmental Condition Analysis: In corrosive chemical environments—such as industrial wastewater treatment tanks containing acidic substances—the cast iron tie rod performs better than plastic or metal models due to its inherent chemical resistance.

| Feature | Cast Iron Tie Rod | Plastic (PVC) Tie Rod | Metal (Spring-Type) Tie Rod |

|---|---|---|---|

| Compressive Strength | Very High | Good | High |

| Cost | Medium | Very Low | High |

| Length Adjustability | No (Fixed Length) | Yes (Pipe Adjustment) | Yes (Fully Custom) |

| Installation Complexity | Low | Medium (Multiple Parts) | Medium |

| Corrosion Resistance | Good (Excellent in Concrete) | Very High | Good (Coating Dependent) |

| Best Application | Heavy structures, high pressures, corrosive environments | Economical projects, swimming pools | Custom and non-standard wall thicknesses |

The Zeman Advantage: Quality, Precision, and Reliability in Waterproof Tie Rod Production

Choosing a reputable supplier is as important as selecting the right product. Zeman Company delivers confidence and quality to civil projects through its competitive advantages.

- Production Scale and Technology: With an annual production capacity exceeding 16,000 tons and the use of robotic production lines and modern machinery, Zeman can supply large-scale projects in the shortest possible time with consistent quality. All products are manufactured in compliance with recognized international standards such as DIN.

- Raw Material Quality: Final product performance depends on raw material quality. By using high-grade ductile cast iron and durable PVC materials, Zeman delivers products with predictable and reliable performance under real project conditions.

- International Experience and Credibility: With over two decades of experience (established in 1999) and a successful presence in export markets such as Iraq, Tajikistan, Turkmenistan, Qatar, and the UAE, Zeman’s product quality has been proven on a global scale—demonstrating its ability to compete with leading international manufacturers.

- Technical Support and Professional Consulting: Zeman’s engineering team provides expert consultation to help project executors select the most accurate and suitable product. This support prevents costly errors—such as incorrect sizing of metal tie rods or improper selection for specific environments—transforming Zeman from a mere supplier into a trusted technical partner.

Frequently Asked Questions About Waterproof Tie Rods

Can waterproof tie rods be reused?

No. The main body of the waterproof tie rod—whether cast iron, plastic, or metal—remains embedded in the structure after concreting and becomes part of the permanent waterproofing system. These components are single-use. However, the external bolts used to clamp the formwork can be reused in other projects after dismantling.

What is the main difference between a waterproof tie rod and a standard bolt?

A standard bolt (fully threaded or double-ended) is temporary and removed after concrete setting, leaving a hole that requires secondary waterproofing. In contrast, a waterproof tie rod is a permanent component that remains within the concrete and itself acts as the primary water barrier, eliminating any need for additional operations.

What factors determine the price of waterproof tie rods?

The most important factors include:

- Material: Plastic (PVC) is the least expensive option, while cast iron and metal are priced higher due to material costs and more complex production processes.

- Dimensions: In plastic and metal models, increased length directly increases price.

- Manufacturing Process: One-piece casting for cast iron and precision welding for metal models affect final pricing.

What size metal waterproof tie rod should be ordered for a 40 cm thick wall?

To calculate the correct size, subtract the length of the two plastic cones (3 cm each) from the wall thickness. Therefore, for a 40 cm wall, you should order a 34 cm metal tie rod (40 − (3 + 3) = 34), so that the final installed length is exactly 40 cm.

Price Inquiry and Technical Consultation for Waterproof Tie Rods from Zeman Experts

Choosing the right formwork equipment is the cornerstone of building strong and durable concrete structures. Although the waterproof tie rod may seem like a small component, it plays a vital role in ensuring long-term waterproofing and stability.

Zeman’s technical and sales team is ready to support you with specialized consultation to help you select the optimal type and size of waterproof tie rod for your specific project. To receive additional information, technical product catalogs, and price quotations based on order volume, please contact us through the channels below. Our experts are prepared to respond and deliver engineered solutions for even the most challenging projects.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.