Wall Mesh_ A Comprehensive Guide to Modern Seismic Restraint Systems for Walls in Building Construction

In this comprehensive article, we provide an in-depth review of wall mesh: from its definition and history to its types, advantages, disadvantages, applications, execution method, and comparison with other systems. Our goal is to deliver fluent, clear, and evidence-based information so that audiences such as civil engineers, architects, builders, and even homeowners can make informed decisions.

In today’s construction industry, where safety and structural stability are more critical than ever, modern strengthening systems such as wall mesh play a key role. Iran, as an earthquake-prone country, has always faced seismic challenges, and the need for efficient methods to protect non-structural walls has been strongly felt. Wall mesh, as an economical and effective alternative to traditional methods such as metal wall posts, has attracted the attention of engineers, contractors, and building owners.

Zeman Company, with over 30 years of experience in manufacturing construction equipment such as concrete formwork and scaffolding systems, can be considered a reliable source for strengthening-related equipment. To view Zeman’s successful projects, visit the projects page: Zeman Concrete Structure Company Projects

Definition and Fundamentals of Wall Mesh

Wall mesh, as a modern method in civil engineering, is based on the use of composite materials. This system typically consists of fiberglass mesh and a mineral coating layer applied to the wall surface.

Wall mesh is a modern seismic restraint system for non-structural walls, composed of fiberglass mesh and mineral plaster, and is considered a suitable replacement for traditional metal wall posts. This method increases wall resistance against earthquakes, has lower weight, and is faster and more economical to execute. According to research conducted by Iran’s Road, Housing, and Urban Development Research Center, wall mesh can significantly control wall movements and prevent their collapse, especially in earthquake-prone regions of Iran.

Key points:

- Simple definition: Wall mesh is a network of glass fibers (fiberglass mesh) that is installed on the wall with a layer of plaster (gypsum or cement-based) to increase its strength.

- Main advantages: Increased seismic resistance, reduced execution cost and time, lightweight nature, and prevention of wall cracking. Evidence indicates that this system can extend the service life of a building by up to 30 years.

- Applications: Mainly used for strengthening internal and external walls in residential, commercial, and historical buildings, particularly against lateral forces such as earthquakes and wind.

- Challenges: Requires precise execution to avoid potential issues such as weakness in humid environments if alkali-resistant mesh is not used.

- Recommendation: For proper selection, consulting specialists and using standard products is essential; for example, reviewing strengthening-related products on websites such as Zeman can be helpful.

Execution of Wall Mesh

Its execution includes stages such as installing angle profiles, placing the mesh, and applying plaster. Further details will be provided in the following sections.

For more information about related construction equipment, visit the Concrete Formwork Equipment page of Zeman Company.

What Is Wall Mesh? Review of Fundamentals and Structure

Wall mesh (Wall Mesh) is a composite system used to reinforce and restrain non-structural walls. These walls, which do not carry the primary structural loads (such as internal partition walls or façade walls), are vulnerable to movement, cracking, or even collapse during earthquakes or other lateral forces such as wind. Wall mesh strengthens these walls by using a network of glass fibers (fiberglass mesh) and a mineral plaster layer (gypsum or cement-based).

The structure of wall mesh includes the following main components:

- Fiberglass mesh: A strong network of glass fiber strands with high tensile strength. This mesh is typically available in weights ranging from 120 to 160 grams per square meter.

- Plaster: A thin layer (approximately 5–10 mm) of mineral mortar applied over the mesh to fix and stabilize it.

- Angles and connections: Galvanized L-shaped profiles used to connect the mesh to the structural frame (beams and columns).

Unlike metal wall posts that use heavy profiles, this system is lightweight and does not require complex equipment for execution. According to reports by the Road, Housing, and Urban Development Research Center, wall mesh can reduce wall displacement by up to 50% and prevent seismic damage. For related equipment such as modern scaffolding systems that are useful in wall mesh execution, visit the scaffolding page of Zeman Company.

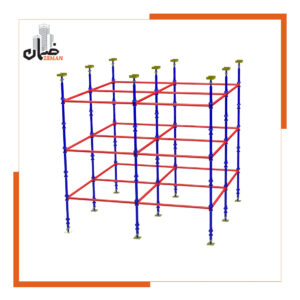

1. Cup Lock Scaffold: This system is mainly used for tall structures and load-bearing applications and does not directly play a role in wall mesh execution; however, it is highly suitable for safe access when installing wall mesh at height.

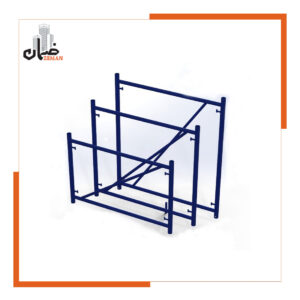

2. H-Frame Scaffold: H-frame scaffolds are mostly used for canopies, façade works, and lighter tasks. During wall mesh execution on building floors, this scaffold is used to create a working platform and provide access to the mesh installation area.

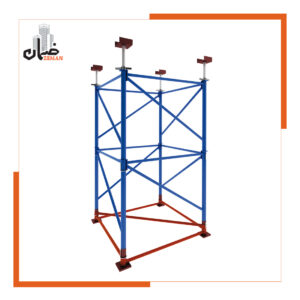

3. Omega Triangular Scaffold: Triangular scaffolding is typically used for slab formwork and the execution of concrete ceilings. Its relation to wall mesh arises when wall mesh is installed near ceilings or concrete beams and requires support or underslab access.

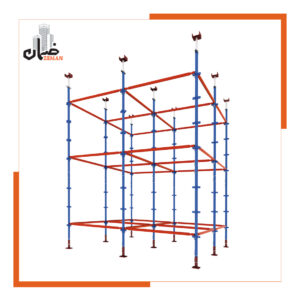

4. Hammer Scaffold: Hammer scaffolding, with its high installation speed, is used for general construction works and masonry. In projects where wall mesh is installed on block or clay brick walls, this scaffold is a common solution for installing meshes at height and supporting the workforce.

5. Traditional Scaffold (Tube and Coupler): The most precise and flexible model for various operations, including installing wall mesh on irregular walls or in confined spaces. Due to its adjustable nature, it is suitable for detailed works, corners, edges, and varying heights.

6. Service Scaffold: This type of scaffold is mainly used to provide access for worker movement, circulation paths, and the simultaneous execution of multiple tasks on projects. In projects where wall mesh is applied on several façades, service scaffolding plays the role of creating access routes and working platforms.

The history of wall mesh dates back to recent decades. This method was initially developed in earthquake-prone countries such as Japan and the United States and was later approved in Iran, in accordance with Seismic Code 2800, as a replacement for wall posts. In recent years, Iranian companies such as Wall Mesh Group and Afzir have introduced standard products compliant with national regulations.

Types of Wall Mesh: Selection Based on Project Requirements

Wall mesh is produced in various types to adapt to different conditions. Selecting the appropriate type depends on the wall type, environment, and seismic risk level. The main types include:

- Standard Fiberglass Wall Mesh: Suitable for dry and interior environments. This type is more economical but has lower resistance to alkalinity (such as cement).

- Alkali-Resistant Fiberglass Wall Mesh (AR-Glass): Ideal for humid environments or exterior walls. With its special coating, this type has higher durability and is used with cement-based plasters.

- Carbon Wall Mesh: Used for high-risk projects such as historical buildings. It offers higher tensile strength but is more expensive.

- Wall Mesh Strips: Supplied in strip form (20–30 cm wide) for small walls or localized repairs.

Comparison table of wall mesh types:

| Wall Mesh Type | Alkali Resistance | Weight (g/m²) | Main Application | Approximate Price (Toman/m²) |

| Standard Fiberglass | Low | 120–140 | Dry interior walls | 50,000–70,000 |

| AR-Glass | High | 140–160 | Exterior and humid walls | 80,000–100,000 |

| Carbon | Very High | 160+ | Historical and sensitive buildings | 150,000+ |

| Strip Type | Medium | 120 | Localized repairs | 40,000–60,000 |

This table is based on Iran market data in 2025. For similar products such as special concrete formwork used in strengthening works, visit Zeman Company’s modular formwork page.

Advantages of Wall Mesh in Construction_Why Is It Engineers’ First Choice?

Wall mesh offers numerous advantages that make it a superior option. According to studies published on specialized websites, these advantages include:

- Increased seismic resistance: Wall mesh strengthens walls against lateral forces and prevents overturning. Research indicates that this system can absorb up to 40% of earthquake energy.

- Reduced structural weight: Unlike metal wall posts that add significant weight, wall mesh is lightweight and does not impose additional loads on the structure, making it ideal for older buildings.

- Speed and ease of execution: Wall mesh installation is completed in only five main steps and requires less specialized labor, reducing project duration by up to 50%.

- Economic efficiency: Its cost is approximately 30–40% lower than traditional methods. Additionally, preventing cracking in finishing layers reduces future repair costs.

- Durability and environmental resistance: Alkali-resistant types perform well against moisture and corrosion, extending the building’s service life.

- Flexibility: Applicable to block, brick, AAC walls, and even historical buildings without damaging appearance.

For example, in large projects such as historical building renovations, wall mesh has significantly reduced costs. For supporting equipment such as adjustable props used in executing such systems, visit the slab and support props page of Zeman Company.

Disadvantages of Wall Mesh: Challenges and Solutions

Although wall mesh has many advantages, several disadvantages should also be considered:

- Need for precise execution: Improper plaster application may cause weaknesses. Solution: use trained teams.

- Environmental sensitivity: Standard types perform poorly in alkaline environments. Solution: select AR-Glass mesh.

- Initial material cost: For small projects, it may seem costly, but it results in long-term savings.

- Height limitation: Walls taller than 4 meters require additional reinforcement.

Table of Wall Mesh Disadvantages and Solutions

| Disadvantage | Potential Impact | Proposed Solution |

| Improper execution | Weak connections | Team training and engineering supervision |

| Moisture sensitivity | Mesh corrosion | Use alkali-resistant type |

| Material cost | Higher initial budget | Compare with long-term costs |

| Height limitation | Inefficiency for tall walls | Combine with traditional wall posts |

These challenges can be effectively managed with proper planning.

Applications of Wall Mesh in Building Strengthening

Wall mesh has wide applications, particularly in Iran, where more than 80% of buildings require strengthening:

- Residential buildings: Restraining interior walls to prevent earthquake damage.

- Commercial and office buildings: Strengthening exterior façades against wind and seismic forces.

- Historical structures: Enhancing strength without damaging the original fabric.

- Renovation projects: Suitable for old block or AAC walls.

- Hospitals and schools: Where safety is a top priority.

According to a report by ILNA, wall mesh can increase a building’s service life by up to 30 years. For similar projects, visit the Solt Hotel Shiraz Project of Zeman Company.

Wall Mesh Installation Method_Step by Step with Execution Tips

Wall mesh installation is simple and consists of five main stages:

- Surface preparation: Cleaning the wall from dust and debris.

- Angle installation: Fixing L-profiles to beams and floors using bolts or epoxy adhesive.

- Mesh placement: Spreading fiberglass mesh over the wall with 1–2 meter spacing.

- Plaster application: Applying the mineral layer with appropriate thickness.

- Curing and inspection: Quality control after 24–48 hours.

To view execution tools such as clamps and bolts, visit Zeman Company’s formwork accessories.

Comparison of Wall Mesh and Traditional Wall Posts

Compared to metal wall posts, wall mesh offers more advantages:

- Lighter (50% less weight)

- More economical (30% lower cost)

- Faster execution (twice the speed)

- However, wall posts are more resistant for very tall walls.

Comparison table:

| Criterion | Wall Mesh | Metal Wall Post |

| Weight | Lightweight | Heavy |

| Cost | Low | High |

| Execution speed | High | Medium |

| Seismic resistance | Excellent | Good |

Important Tips for Selecting and Purchasing Wall Mesh

- Check the weight (grammage) and mesh type.

- Engineering Organization approval.

- Choosing a reputable supplier.

Conclusion

Wall mesh, as a modern, lightweight, and economical system for strengthening non-structural walls, has brought about a major transformation in Iran’s construction industry. By utilizing fiberglass mesh and mineral plaster, this method not only increases the seismic resistance of walls but also eliminates common problems such as cracking, excessive weight of metal wall posts, and high repair costs.

In an earthquake-prone country such as Iran, the use of wall mesh can be a smart, cost-effective, and code-compliant solution. Selecting the appropriate mesh type, precise execution, and the use of standard equipment play a key role in the success of this system.

Ultimately, wall mesh is a modern, practical, and reliable option for engineers, builders, and property owners seeking to enhance safety, durability, and overall structural quality.