Traditional Scaffolding

Despite decades of continuous presence in Iran’s construction industry, Traditional Scaffolding—also known as the Tube and Coupler Scaffolding System—remains the most widely used, most flexible, and most recognized method for providing access at height. This system, which stands as a symbol of strength and adaptability, relies on two simple yet fundamental elements—tubes and couplers—to empower engineers and skilled scaffolders to accommodate the most complex geometries and gain access to the most difficult and hard‑to‑reach locations. It should also be noted that the modern, prefabricated version of this system is H‑Frame Scaffolding.

Zaman Company, as one of the leading manufacturers of scaffolding equipment in Iran, takes pride in producing the highest‑quality standard scaffolding tubes and couplers. In this comprehensive guide, the company aims to share its full knowledge and practical experience regarding this fundamental system—from component introduction to erection principles and safety requirements.

Traditional Scaffolding

What Is Traditional Scaffolding? The Philosophy of Unlimited Flexibility

Traditional tube and coupler scaffolding is more than a collection of steel components; it is a shared language and a craftsmanship deeply rooted in the construction industry. This system, recognized worldwide as the cornerstone of safe access to height, is built upon a simple yet powerful philosophy: creating a robust and secure structure by connecting two fundamental elements—tubes and couplers—at any point and at any angle required by the project. This simple principle opens the door to virtually unlimited flexibility.

Why Is It Still Widely Used Despite Modern Systems?

Although traditional (tube and coupler) scaffolding remains widely used in many construction projects due to its high flexibility, modern systems are often better alternatives for high‑rise structures and projects where execution speed and modular safety are the top priorities. If you are considering safer and prefabricated systems, we strongly recommend reviewing the technical specifications and advantages of H‑Frame Scaffolding on its dedicated page to better understand its performance differences compared to traditional systems.

One might ask why, despite the availability of fast and safe modular systems, traditional scaffolding remains the first choice for many projects. The answer lies in its unparalleled flexibility. In projects with highly complex geometries—such as scaffolding around a mosque dome, the façade of a historic building with intricate ornamentation, or access to interwoven pipelines in a refinery—modular systems face significant limitations. In such scenarios, only the tube and coupler system allows skilled scaffolders to tailor the structure like a custom‑fitted garment, adapting it precisely to the irregular and unique form of the main structure and providing access to every required point.

Traditional scaffolding is assembled using scaffolding tubes with an outer diameter of 48.3 mm, supplied in various lengths, and fixed and swivel couplers with four bolts. This type of scaffolding is the most common system for scaffolding and formwork support applications; however, it does not inherently provide sufficient safety when compared to modern systems. The scaffolding tubes are typically welded (seamed) steel pipes with various wall thicknesses, and the couplers are manufactured from ductile (nodular) cast iron.

Technical Definition: A Skill‑Based, Non‑Modular System

From an engineering perspective, traditional scaffolding is classified as a non‑modular system. What does this mean? Unlike modern scaffolding systems (such as wedge‑lock or omega systems) that feature predefined and standardized connection points, tube and coupler scaffolding has no preset nodes. The exact location of each connection, its angle, and the type of coupler used are determined entirely on site by a skilled execution team (professional scaffolders). This characteristic elevates human expertise to the highest level of importance, as the strength and safety of the entire structure are directly dependent on the knowledge, precision, and experience of the personnel erecting it.

In‑Depth Breakdown of Tube and Coupler Scaffolding Components: The System’s Beating Heart

The final quality and safety of traditional scaffolding are directly dependent on the quality of each individual component. At Zaman Company, we focus on the standardized production of every one of these critical parts.

1. Scaffolding Tube: The Structural Lifeline

The most important component of the system is the scaffolding tube. A standard scaffolding tube must meet specific criteria:

- Outside Diameter:

The global standard for scaffolding tubes is an outside diameter of 48.3 mm, commonly referred to as a “Size 5” tube. This diameter ensures optimal compatibility with all standard couplers. - Wall Thickness:

One of the most critical parameters. Scaffolding tubes are typically produced in thicknesses of 2.0, 2.3, and 2.5 mm. Heavy‑duty tubes with a 2.5 mm wall thickness provide the highest load‑bearing capacity and safety margin and are the preferred choice of professionals. At Zaman Company, our focus is on producing true heavy‑duty tubes with verified thickness. - Tube Weight:

The tube weight is directly related to its wall thickness. For example, each meter of a 2.5 mm thick scaffolding tube weighs approximately 2.4 kg. Knowing the exact weight is essential for load calculations and transportation planning. - Tube Type:

Tubes may be seamed (welded) or seamless. Seamed tubes are more common and economical for scaffolding applications, provided that they are manufactured with proper, standard welding quality.

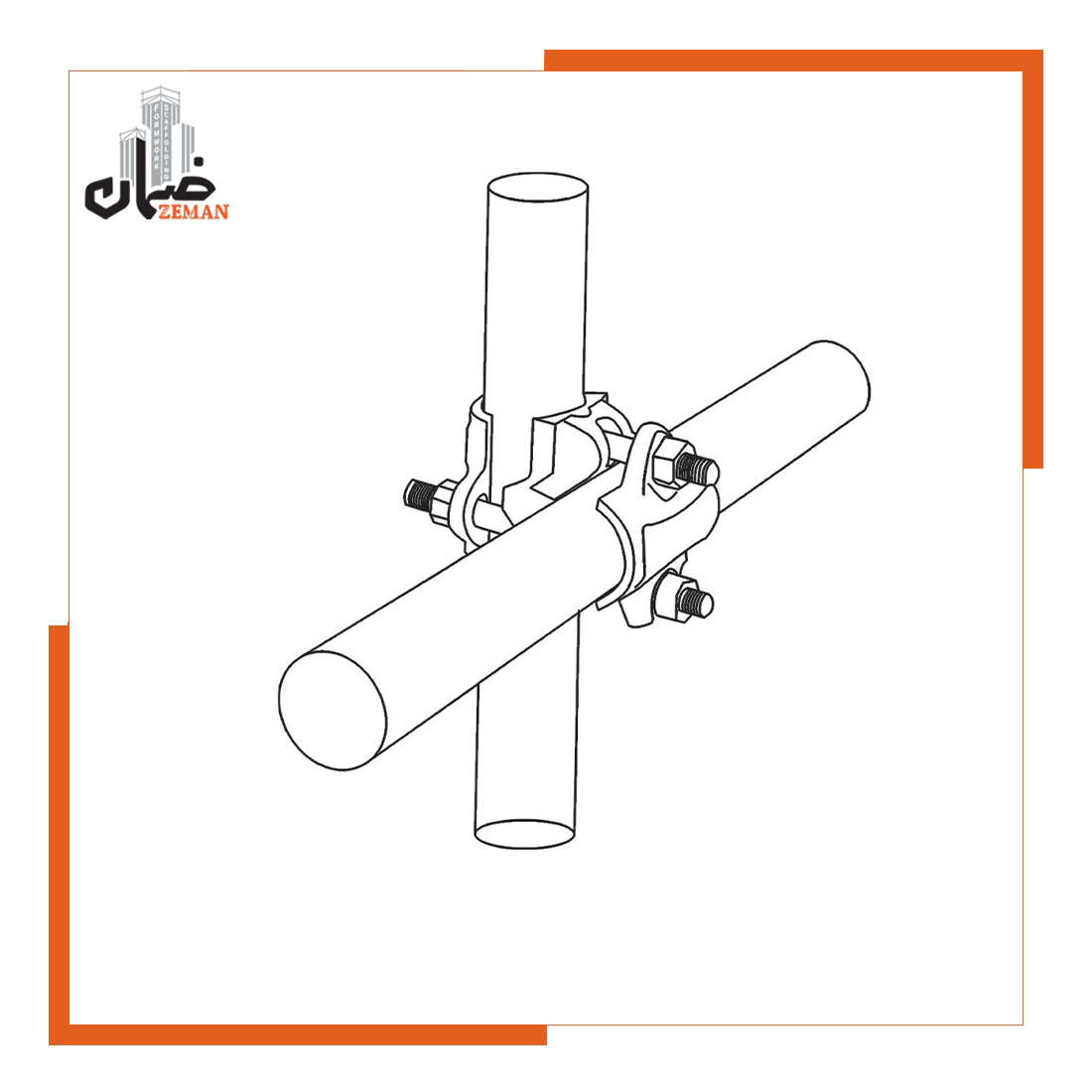

2. Right‑Angle Coupler: The Backbone of Connections

The right‑angle coupler is the most widely used type of coupler, designed to connect two tubes at a perpendicular (90‑degree) angle. A standard right‑angle coupler is manufactured from ductile (nodular) cast iron to provide high resistance against impact and compressive forces. The standard weight of this coupler typically ranges from 1,300 to 1,600 grams. The quality of the bolts, nuts, and washers used plays a critical role in the integrity of the connection.

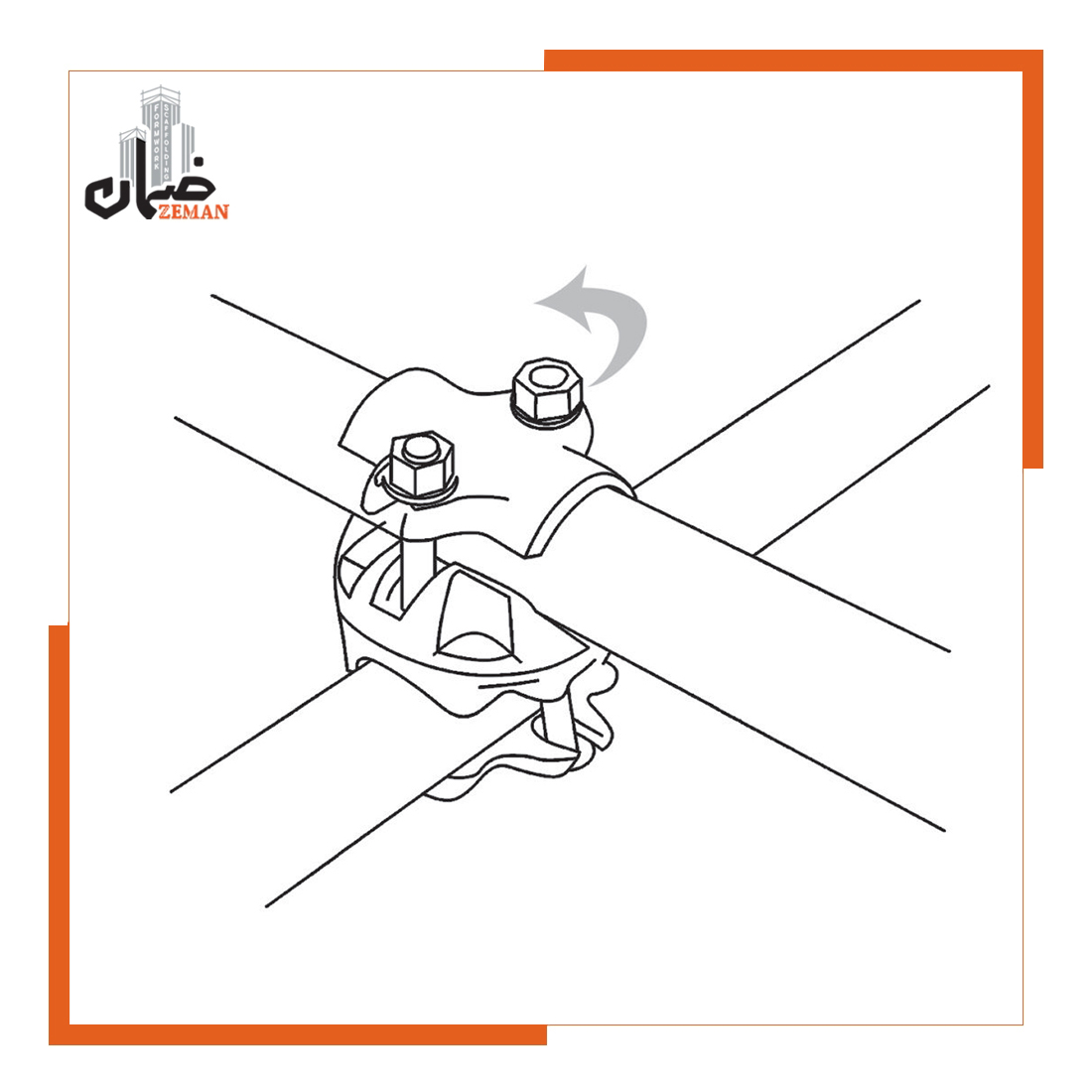

3. Swivel Coupler: The Key to Flexibility

Whenever two tubes need to be connected at angles other than 90 degrees, the swivel coupler comes into play. This coupler is essential for installing diagonal braces and ensuring overall structural stability. Its 360‑degree rotational capability allows scaffolders to adapt the structure to virtually any geometric configuration.

4. Girder (Beam) Coupler: Connecting to the Main Structure

To securely connect the scaffolding structure to steel beams and profiles of the main building, a girder coupler is used. Its specialized design allows it to firmly grip the beam flange, providing a reliable anchorage point for tying the scaffold to the main structure.

5. Other Essential Components

- Connecting Pin / Spigot:

Used to vertically connect two tubes and increase the overall height of the scaffold. - Base Plate:

A steel plate installed beneath vertical standards to distribute the load evenly across the ground surface. - Adjustable Base Jack:

Used for precise leveling of the entire structure on uneven or sloped ground, which is critical for initial stability.

Key Features of Traditional Steel Scaffolding

- Manufactured from scaffolding tubes with a diameter of 48.3 mm in various lengths

- Connections made using fixed and swivel four‑bolt couplers made of ductile cast iron

- The most common scaffolding and formwork support system in traditional construction projects

- Use of welded tubes with different wall thicknesses based on project requirements

- Fast and highly flexible execution for a wide range of building structures

- Lower inherent safety compared to modern systems such as modular or triangular scaffolding

- Suitable for projects with limited budgets or temporary applications

The Craft of Scaffolding: Step‑by‑Step Principles for Safe Erection

Erecting traditional scaffolding is a specialized skill that requires strict adherence to engineering and safety principles. The main steps include:

- Ground Preparation:

The supporting surface must be firm, level, and stable. On soft soil, sole boards must be installed before placing base plates. - Base Lift Installation:

The first row of standards and ledgers is installed with precision, and vertical alignment is verified using a spirit level. This stage forms the foundation of the entire structure. - Installation of Diagonal Bracing:

Cross bracing must be installed immediately after each lift. These braces prevent lateral movement and buckling of standards, ensuring structural rigidity. - Installation of Working Platforms:

Working platforms, typically made of timber boards or standard steel decks, must span the full width of the scaffold, be securely fixed, and be equipped with toe boards. - Tying to the Main Structure:

One of the most critical safety steps. At standard horizontal and vertical intervals, the scaffold must be securely tied to structurally sound parts of the main building to resist wind and lateral loads.

Advantages and Challenges: A Realistic Assessment of Traditional Scaffolding

Advantages: Why Traditional Scaffolding Remains Popular

- Unmatched Flexibility: Can be erected in virtually any geometry and for any type of project.

- Wide Availability: Components are readily available throughout the country.

- Lower Initial Component Cost: The cost of individual tubes and couplers is lower compared to modular system components.

- Ease of Repair and Replacement: Damaged couplers or bent tubes can be easily replaced individually.

Challenges: What You Should Know Before Choosing

- High dependency on workforce skill: the overall safety of the system relies heavily on the expertise of the erection team.

- Slower erection speed: tightening each individual bolt is time‑consuming and reduces project speed.

- Higher labor costs: the need for skilled scaffolders increases workforce expenses.

- Large number of small components: risk of loss or falling parts on site is relatively high.

The Zaman Gold Standard: Why Source Your Tubes and Couplers from Us?

Although traditional scaffolding is an established system, its production can be thoroughly modern and standardized. At Zaman Company, we redefine quality:

- Commitment to True Wall Thickness: We manufacture scaffolding tubes with actual, verified wall thicknesses (2.5 mm heavy‑duty). This commitment guarantees structural strength and safety.

- Superior Ductile Cast Iron Couplers: Our couplers are produced from ductile cast iron, providing the highest resistance to impact and compressive loads.

- Industrial‑Scale Production and Quality Control: All products undergo strict quality inspections before leaving the factory.

- Direct Purchase and Competitive Pricing: By buying directly from Zaman, you eliminate intermediaries and receive factory‑direct pricing for scaffolding tubes and fittings.

Frequently Asked Questions (FAQ) About Traditional Scaffolding

In this section, we provide comprehensive answers to key technical questions that contractors, engineers, and scaffolding equipment buyers commonly ask. Our goal at Zaman Company is to offer transparent information to support informed decision‑making.

1. What Is the Exact Weight per Meter and per 6‑Meter Length of Scaffolding Tube?

This is one of the most important questions for logistics and load calculations. Tube weight is directly related to wall thickness. At Zaman Company, we focus on producing standard heavy‑duty tubes:

Heavy‑Duty Tube (2.5 mm thickness):

- Weight per meter: approximately 2.42 kg.

- Weight per 6‑meter length: approximately 14.5 kg.

Semi‑Heavy Tube (2.3 mm thickness):

- Weight per meter: approximately 2.25 kg.

- Weight per 6‑meter length: approximately 13.5 kg.

Key note: When purchasing, always check the weight of a single tube. A weight lower than these standard values indicates reduced wall thickness and, consequently, lower quality and safety.

2. What Is the Difference Between Forged Couplers and Pressed (Stamped) Couplers, and Which Is Better?

These two coupler types differ significantly in manufacturing process and structural strength:

- Pressed (Stamped) Coupler:

Made from steel plates that are pressed into shape and welded together. This type is lighter (approximately 900–1,200 g) and more economical but offers lower resistance to impact and heavy loads. - Forged Coupler:

Manufactured by heating ductile cast iron and forging it under heavy hammers, creating a dense and integrated molecular structure. Forged couplers are heavier (approximately 1,300–1,600 g) and provide significantly higher resistance to impact, pressure, and deformation.

Technical Conclusion:

For high‑risk, high‑rise, and heavy‑load projects where safety is the top priority, forged couplers are the unequivocal choice of professionals. Zaman Company specializes in the production of standard forged couplers.

3. Is It Acceptable to Use Second‑Hand Scaffolding Tubes?

Using second‑hand equipment involves considerable risk and must be approached with extreme caution. Second‑hand tubes may only be acceptable if all of the following conditions are met:

Free from any bending or deformation along the tube length.

Free from cracks, splits, or severe corrosion. Surface rust is acceptable, but corrosion that reduces wall thickness is highly dangerous.

Tube ends must be intact and not crushed, ensuring proper insertion of connection pins.

However, as a manufacturer, we strongly recommend investing in new, certified equipment. The full load history and stress exposure of second‑hand tubes can never be reliably verified.

4. What Is the Standard Spacing for Tying Scaffolding to a Wall?

Tying scaffolding to the main structure is the most critical factor in ensuring stability against wind and lateral loads. According to international standards, the general guideline is:

- Horizontal spacing: ties should be installed at a maximum of every two bays (approximately 4–5 meters).

- Vertical spacing: the first tie should be installed at a height not exceeding four times the scaffold width, followed by ties every two to three lifts (approximately 6–8 meters).

- Important note: these values are general guidelines. For sheeted scaffolds or wind‑exposed locations, tie spacing must be reduced based on structural engineering calculations.

5. Approximately How Much Tube and How Many Couplers Are Needed for 100 m² of Façade Work?

This is an estimate and exact quantities should be determined based on project drawings and details. However, as a rule of thumb for a relatively simple façade:

- Tubes:

Approximately 2.5 to 3 meters of tube length is required per square meter of façade. For 100 m², this equals about 250–300 meters of tube (roughly 40–50 pieces of 6‑meter tubes). - Couplers:

Approximately one coupler is required for every 1.5 to 2 meters of tube (including right‑angle and swivel couplers). This results in approximately 150–200 couplers for the project.

Again, this is only an approximation. To avoid excess cost or shortages, consulting with our technical experts is the most accurate approach.

6. In Which Situations Does Traditional Scaffolding Clearly Outperform Modular Systems?

Despite all the advantages of modern systems, traditional scaffolding remains unmatched in specific scenarios:

Extremely complex geometries: scaffolding around domes, statues, historic buildings with elaborate ornamentation, and complex industrial pipe racks where modular systems lack adaptability.

Small, localized repair projects: when access to only a specific point is required, erecting a small tube and coupler scaffold is often faster and more economical than transporting and installing a modular system.

Limited initial capital: when contractors face financial constraints, purchasing tube and coupler components gradually may be more feasible than the upfront investment required for modular systems.

7. What Technical Factors Should Be Considered When Purchasing Tubes and Couplers?

To ensure a smart and safe purchase, pay close attention to the following points:

Weigh the tube: compare the weight of a single tube with standard values (approximately 14.5 kg for a heavy‑duty 6‑meter tube). This is the most reliable way to verify actual wall thickness.

Inspect weld quality: for seamed tubes, the weld seam must be uniform, free from cracks, and without excessive buildup.

Check coupler material and weight: choose forged couplers and verify their weight (no less than 1.3 kg). Examine bolt threading quality and smooth operation.

Buy from a reputable manufacturer: purchasing directly from a trusted factory such as Zaman ensures certified products with full traceability.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.