The Correct Method for Waffle Slab Formwork Removal

Introduction to Waffle Slab Formwork Stripping

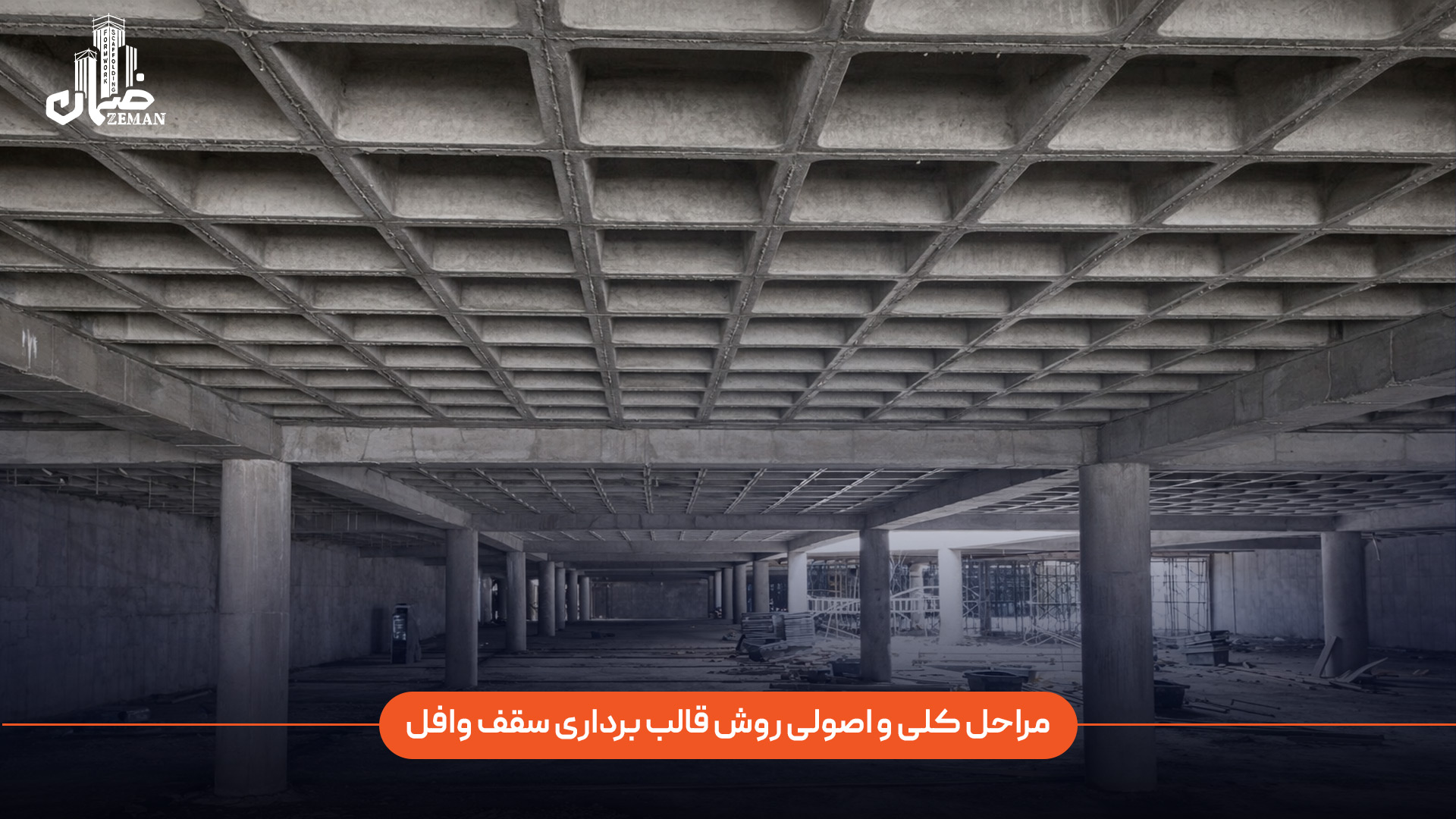

The waffle slab, as one of the most advanced and cost-effective floor systems in modern civil construction projects, plays a significant role in reducing structural weight, optimizing concrete consumption, and increasing achievable spans. This type of slab, which is executed as a grid of intersecting concrete ribs, requires precise and engineered formwork; accordingly, waffle slab formwork stripping is considered one of the most sensitive stages of its execution. Any error in the timing or method of stripping can lead to cracking, reduced strength, or even serious structural damage.

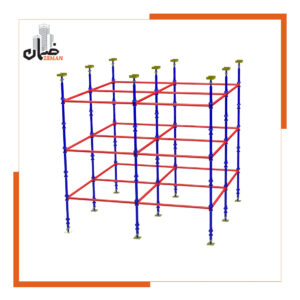

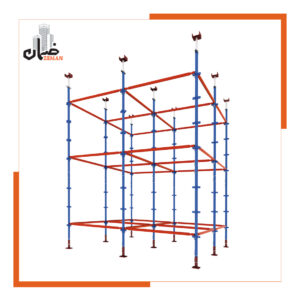

Waffle slab formwork stripping does not merely mean removing the forms; rather, it is a fully technical process dependent on parameters such as concrete strength, climatic conditions, formwork type, shoring arrangement, and the supporting systems beneath the slab. In this context, the use of standard formwork and scaffolding equipment plays a decisive role in project safety and final quality. For example, utilizing systems such as cuplock scaffolding or cuplock scaffold, due to their high load-bearing capacity and rapid assembly, significantly increases the safety factor during the stripping phase.

In projects where the waffle slab is executed at height, adherence to proper stripping principles becomes even more critical. Under such conditions, the use of specialized formwork equipment for work at height, standard props, and appropriate bracing systems prevents potential hazards. Moreover, maintaining shores and slab props until the concrete reaches the required strength is an indispensable technical requirement. Equipment such as simple slab props or more advanced systems available through the purchase of slab and support props play a key role at this stage.

On the other hand, the type of forms used in a waffle slab directly affects the stripping method and timing. Waffle molds may be plastic, composite, or hybrid, each with its own specific stripping instructions. In many projects, the simultaneous use of modular formwork systems in different parts of the structure requires precise coordination between the formwork installation and stripping teams to ensure that structural loads are properly transferred.

Another important point is the relationship between waffle slab stripping and other formwork sections of the structure. For instance, if formwork operations for the foundation or concrete wall formwork are being carried out simultaneously, the schedule for slab formwork stripping must be planned in such a way that it does not disrupt the overall project workflow. This coordination requires an accurate understanding of concrete behavior and the supporting systems beneath the slab.

In this content, we have attempted to provide a comprehensive review of waffle slab formwork stripping based on a fully practical approach and on-site experience. From the appropriate stripping time to safety considerations, the waffle slab structure, and the proper steps for removing the forms, all topics will be explained step by step and in a practical manner so that contractors, engineers, and project executors can manage this sensitive stage with full confidence.

Timing of Waffle Slab Formwork Stripping

One of the most important and sensitive issues in waffle slab execution is determining the appropriate time for formwork stripping. Contrary to the belief of some executors, waffle slab stripping is not based solely on experience or project speed; rather, it is entirely dependent on concrete strength, environmental conditions, the type of supporting system, and technical standards. If the forms are removed prematurely, the risk of deflection, cracking, and even localized slab failure increases; if stripping is carried out too late, it results in wasted time and increased project costs.

In general, the timing of waffle slab formwork stripping is divided into two main parts:

- Side forms and waffle molds (permanent or non-permanent forms)

- Shores, props, and supporting systems beneath the slab

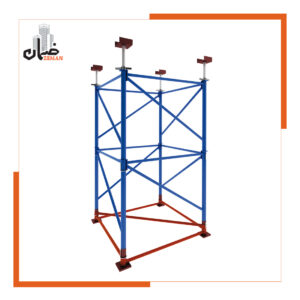

Waffle molds can usually be removed after the concrete reaches its initial strength; however, the shores and props beneath the slab must remain in place until the concrete achieves the strength specified in the drawings or codes. At this stage, the use of safe shoring systems such as triangular scaffolding or triangular shoring plays a very important role in maintaining slab stability.

&

Effect of Concrete Strength on Formwork Stripping Time

The most important technical criterion for determining the time of formwork stripping is the percentage of concrete compressive strength achieved. It is generally recommended that formwork stripping be carried out when the concrete has reached at least 70% of its final strength. Depending on the type of cement, mix design, ambient temperature, and curing conditions, this period can range from 7 to 14 days. In cold weather, this duration increases, while in hot and dry conditions it may be slightly reduced, provided that proper curing is performed.

In projects where modern scaffolding systems are used, such as hammer scaffolding or H-frame scaffolding, controlling the loads applied to the slab becomes easier and the safety of formwork stripping increases. Due to uniform load distribution, these systems allow for gradual removal of the formwork.

The Role of Props and Supporting Equipment

Slab props are an integral component of waffle slab formwork and stripping operations. The use of standard equipment such as U-head slab props or slab and support props ensures that load transfer from the slab to the ground is carried out safely. During formwork stripping, props must be released gradually and in a controlled manner to prevent sudden shock loads being applied to the structure.

Additionally, in projects where formwork for other parts of the structure is being executed simultaneously, such as concrete wall formwork or circular column formwork, the stripping schedule of the waffle slab must be arranged in a way that prevents execution interference and avoids transferring additional loads to the freshly poured slab.

Ultimately, it must be emphasized that the formwork stripping time for waffle slabs is not a fixed number and must be determined based on actual project conditions, concrete test results, and the opinion of the supervising engineer. Observing these principles guarantees the durability, safety, and proper performance of the waffle slab throughout the service life of the structure.

Waffle Slab Formwork Stripping Time Based on Form Layout

The layout of formworks in a waffle slab is one of the most influential factors affecting the time and method of formwork stripping. Unlike solid slabs or beam-and-block systems, waffle slab formworks are arranged in a grid pattern at regular intervals, causing the load of fresh and hardened concrete to be transferred in a concentrated and linear manner to the waffle ribs and the under-slab support systems. Therefore, the more precise and uniform the form layout, the safer and faster the formwork stripping process will be.

In waffle slabs, the formworks are typically supported by a shoring system consisting of props, beams, and scaffolding. If the spacing between forms, secondary beams, and props is not properly observed, localized stresses are generated in the concrete, increasing the stripping time. In such cases, the use of stable systems such as cuplock scaffolding helps distribute loads evenly and reduces the risk of slab deformation during form removal.

Effect of Form Layout Direction and Regularity

In projects where waffle forms are arranged with full regularity and aligned with the structural spans, load transfer to props and scaffolding is carried out in a fully controlled manner. This allows the forms to be removed earlier compared to slabs with irregular or modified layouts. Conversely, if due to architectural constraints or execution changes some forms are installed with gaps or cut sections, the stripping time for those areas must be determined with greater caution.

In such projects, the use of modular formwork systems and modular metal formwork helps achieve more accurate form layouts and enables form removal and installation without damaging the concrete. These systems also allow for staged stripping, whereby central forms are removed earlier and edge forms are removed later.

Relationship Between Form Layout and Shoring Type

The waffle form layout is directly related to the type of shoring system beneath the slab. For example, in large spans or thicker slabs, stronger systems such as triangular omega scaffolding or cuplock hammer scaffolding are typically used. These systems allow the forms to be placed closer together, resulting in more uniform load transfer to the ground.

Furthermore, the use of standard props beneath critical slab points plays a significant role in stripping time. Equipment such as U-head props or adjustable props allows for gradual adjustment during form removal, preventing sudden shock loads on the structure.

Role of Side and Perimeter Forms in Stripping Time

In many projects, the waffle slab is connected to walls or columns. If the side forms of walls or columns are removed simultaneously with slab forms, the likelihood of stress concentration at slab edges increases. Therefore, in projects utilizing double-sided wall formwork or single-sided wall formwork, it is recommended that waffle slab formwork stripping be carried out independently and with appropriate time intervals.

In conclusion, proper layout of waffle forms is the key to reducing formwork stripping time and increasing project safety. The more accurate the design and execution of this layout, the faster, more economical, and damage-free the stripping process will be.

Structure and Main Components of the Waffle Slab

To correctly understand the waffle slab formwork stripping method, it is first necessary to become familiar with the structure and main components of this type of slab. A waffle slab is a two-way concrete slab system that reduces the dead weight of the structure by creating regular voids beneath the slab while simultaneously providing desirable structural strength and performance. This grid-like structure enables uniform load transfer to columns and load-bearing walls and allows for the execution of larger spans.

Concrete Slab and Intersecting Beams

The core of a waffle slab system consists of the upper concrete slab and the intersecting beams. These beams are arranged in two perpendicular directions, forming a regular grid that transfers the slab loads to the supports. In fact, these beams are the elements whose geometry is created by the waffle molds. Therefore, precision in formwork execution and the use of standard molds have a direct impact on the final quality of the slab.

In many projects, to achieve better coordination between different structural components, tunnel formwork or precast concrete molds are used in areas adjacent to the waffle slab. This coordination results in more uniform structural behavior of the entire system and allows formwork removal to be carried out with reduced risk.

Precast Concrete Parts Formwork

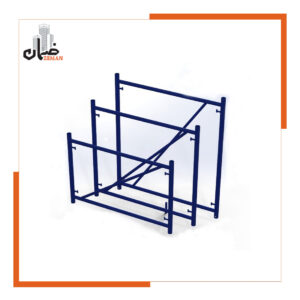

Waffle Molds and Slab Formwork

Waffle molds are typically made of plastic or composite materials and are temporarily placed beneath the slab. After the initial setting of the concrete, these molds can be removed and reused. In some projects, to complete the slab formwork system, ECO slab formwork or a combination of modular formwork systems is used, which both increases execution speed and improves the dimensional accuracy of the slab.

At this stage, the role of formwork connections is extremely critical. Standard connections ensure that the forms remain firmly in place and prevent any unwanted displacement during concrete pouring or form removal.

Shoring and Supporting Systems

Another main component of a waffle slab system is the shoring system beneath the slab. This system is responsible for transferring the load of fresh and hardened concrete to the ground. Props, scaffolding, and beams play a fundamental role in this section. For example, using wall and column support jacks around column areas increases slab stability during formwork removal.

In projects where walls are constructed simultaneously with the slab, coordination between the waffle slab components and special wall formwork systems such as curved wall formwork is of great importance, as uneven load transfer can affect the timing of formwork removal.

The Role of Auxiliary Materials in Waffle Slab Performance

Auxiliary materials such as sole boards, plywood panels, and supporting equipment are also considered indirect yet important components of the waffle slab system. Using high-quality formwork plywood and reviewing the price of sole boards while selecting standard options contribute to increased site safety and easier formwork removal.

Overall, having a precise understanding of the structure and components of a waffle slab is a prerequisite for correct formwork removal. The more accurately these components are selected and executed, the faster, safer, and more damage-free the form removal process will be.

Key Points Regarding the Removal of Waffle Forms

The removal of waffle forms is considered one of the most sensitive stages in the execution of a waffle slab. If carried out without observing technical and safety principles, it can lead to cracking, excessive deflection, or even structural damage. Contrary to the belief of some contractors, formwork removal is not a simple operational task but a fully engineered process that must be performed with proper planning, correct sequencing, and suitable equipment.

Gradual and Phased Formwork Removal

The most important principle in removing waffle forms is that the process must be gradual. Forms should not be removed suddenly or simultaneously over a large area of the slab. Such action introduces sudden shock to the recently hardened concrete and increases the likelihood of deflection or cracking. It is recommended to first remove forms from the mid-spans and then proceed toward the supports to ensure uniform stress distribution.

At this stage, retaining shoring props and jacks beneath the slab is critically important. Even after removing the waffle forms, the supporting systems must remain in place until the concrete reaches its final strength. The use of standard adjustable props such as slab support jacks, shoring jacks, or U-head jacks helps ensure controlled load adjustment when required.

Attention to Environmental Conditions and Concrete Curing

Environmental conditions play a significant role in determining the timing and method of waffle form removal. In cold weather, concrete reaches the required strength more slowly, and formwork removal must be delayed. Conversely, in hot and dry conditions, if concrete curing is not performed properly, early surface cracking may occur. Therefore, before formwork removal, it is essential to ensure proper curing and that the concrete has achieved the required strength.

Additionally, ambient humidity and the level of temporary loading on the slab (such as material stockpiling or worker traffic) must be carefully controlled. Any additional load during formwork removal can increase stress on the waffle slab.

Worker Safety During Formwork Removal

Safety during waffle form removal is of paramount importance. The use of personal protective equipment, proper training of execution crews, and preventing unauthorized personnel from being present beneath the slab are mandatory at this stage. In projects where waffle slabs are executed at height, compliance with working-at-height safety regulations and the use of safe scaffolding and platforms prevent accidents.

It should also be noted that removed forms must not be dropped or lowered in an uncontrolled manner. Form collection should be carried out systematically to prevent damage to the forms and to reduce site hazards.

Inspection of the Slab After Formwork Removal

After removing the waffle forms, a thorough inspection of the underside of the slab is essential. The presence of abnormal cracks, excessive deflection, or concrete separation from reinforcement indicates improper execution or premature formwork removal. If such issues are observed, the opinion of the supervising engineer must be obtained before continuing construction operations.

In general, observing these guidelines during waffle form removal ensures site safety, structural integrity, and an extended service life of the waffle slab.

General and Standardized Steps for Waffle Slab Formwork Removal

The method of waffle slab formwork removal must be carried out based on a phased, controlled process in accordance with technical principles. This process is not merely the dismantling of forms, but rather a series of planned actions aimed at ensuring structural safety, preventing damage to concrete, and guaranteeing the proper performance of the slab throughout its service life.

Stage One: Verification of Concrete Strength and Approval by the Supervising Engineer

The first and most critical step in waffle slab formwork removal is ensuring that the concrete has reached the allowable strength. This is usually determined through the results of concrete test specimens or based on the time specified in relevant codes and the supervising engineer’s judgment. Without this approval, starting formwork removal can pose a serious risk to structural safety.

At this stage, it must also be ensured that no additional loads from other construction activities—such as simultaneous formwork of other structural components—are imposed on the waffle slab, especially if operations like column or wall formwork are being carried out on upper floors.

Stage Two: Gradual Release of Waffle Forms

After confirming the concrete strength, the waffle forms are released gradually, starting from lower-stress zones. Typically, formwork removal begins at mid-spans and proceeds toward the supports. This sequence allows stresses to be distributed uniformly within the slab and ribs, preventing sudden deflection.

At this stage, the forms must be removed without impact or excessive force. The use of trained labor and appropriate tools prevents damage to both the concrete surface and the formwork components.

Stage Three: Retention of Props and Jacks Beneath the Slab

After the waffle forms are removed, the props and jacks beneath the slab must not be dismantled immediately. These elements play a primary role in supporting residual loads and preventing slab deformation. Typically, the jacks remain in place until the concrete reaches its final strength or according to the supervising engineer’s instructions.

In projects using adjustable props, gradual load reduction and step-by-step re-leveling are possible, significantly enhancing safety during the formwork removal process.

Stage Four: Removal of Side and Peripheral Formwork

Once slab stability is confirmed, the removal of side, edge, and formwork around columns or walls can proceed. These forms are usually not primary load-bearing elements; however, their simultaneous removal with waffle forms is not recommended. Observing appropriate time intervals prevents stress concentration along slab edges.

At this stage, care must be taken to avoid introducing any unintended horizontal forces to the slab, particularly in structures where concrete walls are cast simultaneously with the slab.

Stage Five: Final Inspection and Preparation for Subsequent Operations

The final stage of waffle slab formwork removal involves a thorough inspection of the underside of the slab. Checks for deflection, potential cracking, surface quality of concrete, and uniformity of ribs are carried out at this stage. Upon final approval, the slab becomes ready for subsequent operations such as finishing works or formwork installation for the upper floor.

Overall, proper execution of these stages guarantees safety, durability, and correct structural performance of the waffle slab in construction projects.

Final Summary of Waffle Slab Formwork Removal and Frequently Asked Questions

Waffle slab formwork removal is one of the key stages in implementing this structural system and has a direct impact on the final performance, safety, and durability of the structure. As explained in previous sections, success at this stage requires a combination of technical knowledge, proper scheduling, and the use of standard equipment. Any haste or omission of control steps can lead to deflection, cracking, or reduced load-bearing capacity of the slab.

In professional projects, the use of safe scaffolding systems such as service scaffolds or careful evaluation of cuplock scaffolding prices prior to execution plays an important role in cost management and safety enhancement. The choice of scaffolding type should be based on height, slab span, and applied loads—whether in modern systems or in projects that still utilize traditional scaffolding.

Moreover, quality and precision in selecting formwork equipment—especially formwork connections—are highly effective in maintaining form stability and facilitating formwork removal. In some projects, the use of systems such as tunnel formwork or modern solutions like ECO slab formwork improves coordination among structural components and reduces execution errors.

In wall sections and auxiliary elements, coordination between waffle slab formwork removal and systems such as single-sided wall formwork or specialized molds like the ZEMAX variable column formwork is of great importance, as load transfer and execution sequence in these areas directly affect slab performance.

Finally, the use of standard props and supporting equipment, along with evaluating factors such as the price of wall support jacks prior to execution, contributes to better technical and economic decision-making. Selecting an appropriate scaffolding system—considering cuplock scaffolding or reviewing scaffolding prices and purchasing guide—plays a key role in jobsite safety and execution speed.

Frequently Asked Questions About Waffle Slab Formwork Removal

When is waffle slab formwork removal usually carried out?

The timing of formwork removal depends on concrete strength, environmental conditions, and the supervising engineer’s decision. However, in general, phased formwork removal can begin once the concrete reaches at least 70% of its final strength.

Can props and jacks be removed simultaneously with the forms?

No. Props and jacks must remain in place for a specified period after initial form removal to prevent slab deflection and deformation.

Which factors have the greatest impact on formwork removal safety?

Proper removal sequence, use of standard scaffolding and jacks, trained personnel, and control of temporary loads are among the most critical safety factors.

Does the type of waffle form affect the formwork removal method?

Yes. The type of form, its layout, and the supporting system beneath the slab all have a direct impact on the timing and method of formwork removal.

nbsp;