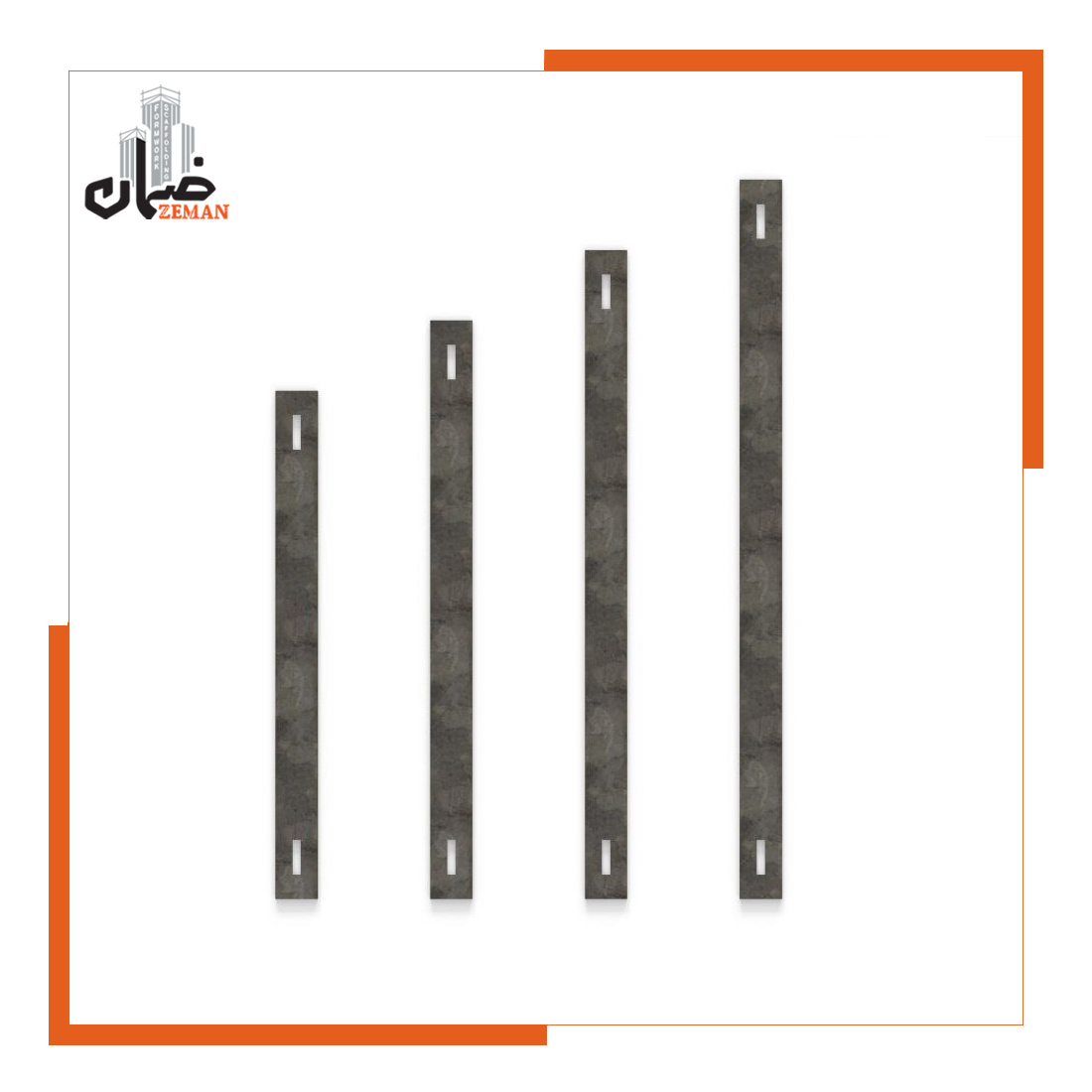

Strap Bolt

Formwork strap bolt is one of the essential components in concrete formwork systems. It is used to distribute the pressure of the formwork bolt evenly across the panels, thereby increasing the safety and structural integrity of the connection.

Definition of Strap Bolt: A strap bolt is a flat metallic component (made of steel) that is installed on both sides of the concrete formwork, through which the formwork tie bolt passes. This strap ensures that the force applied by the nut and bolt is evenly distributed over the surface of the formwork panels.

Application of Strap Bolt: Used on both sides of the formwork (typically in wall or column formwork). It prevents the nut or washer from penetrating into metal or wooden formwork panels. The strap bolt increases the strength of the connection area and reduces stress concentration. It is used in combination with: hook bolt or fully threaded tie rod, bolt nut and washer, and waterproof mid‑bolt (for water‑retaining walls).

Types of Strap Bolts:

- Flat Plate: Suitable for general‑purpose applications.

- Cornered or Curved Type: Designed for better adaptation to special or corner formwork systems.

- Galvanized Type: Provides increased resistance against corrosion and rust.

Strap Bolt

Introduction: A Revolution in Speed and Precision of Formwork with Zaman Strap Bolt

How can the execution speed of shear wall formwork be significantly increased without the slightest compromise in quality? This question represents one of the major concerns of contractors and construction project managers who constantly face tight schedules and financial pressures. The modern construction industry is built on three core principles—speed, productivity, and cost reduction—and despite their effectiveness, traditional formwork methods often become a bottleneck in achieving these objectives.

In response to this critical need, the strap bolt has emerged as an engineered solution and an intelligent alternative to conventional fully threaded tie-rod systems. This seemingly simple yet essential component has transformed the philosophy of formwork from a complex, labor‑intensive process dependent on numerous accessories into an integrated, fast, and efficient system. The use of strap bolts is not merely a technical choice; it is a managerial strategy aimed at risk reduction, resource optimization, and faster return on project investment.

Zaman Company, as one of Iran’s leading manufacturers of concrete formwork equipment, has developed and supplied high‑quality standard strap bolts based on a deep understanding of on‑site execution challenges. These products not only dramatically accelerate formwork operations but also reduce total project costs and deliver smooth, exposed concrete surfaces. This article serves as a comprehensive guide to understanding, selecting, and properly using this key product.

What Is a Strap Bolt? A Technical Breakdown of a Key Component in Concrete Structures

A strap bolt is a flat, elongated metal component resembling a belt or strap, manufactured from high‑strength steel plate. At both ends of the strap, precisely punched holes are provided for connection to formwork panels. The primary and fundamental function of this component is to connect the two faces of concrete formwork externally (at the panel edges) and resist the significant hydrostatic pressure induced by fresh concrete.

This connection method completely eliminates the need for tie rods to pass through the formwork panels. As a result, strap bolts are considered the ideal solution for formwork systems without through-holes, particularly in shear wall construction.

One Component, Multiple Names: Common Market Terminology

The rapid adoption of this technology across construction sites has led to the product being known under various names. Rather than indicating confusion, this diversity reflects the proven performance and widespread acceptance of the strap bolt among contractors and craftsmen. Familiarity with these terms is essential for professionals in the construction industry:

- Tightening Strap: Refers to the primary function of tightening and holding the two formwork faces together.

- Formwork Strap / Formwork Belt: Highlights its primary application in concrete formwork systems.

- Strap-Type Bolt: Describes its dual nature—flat like a strap, while performing the function of a bolt.

- Shear Wall Strap: Directly refers to its most common use in shear wall formwork.

Operating Mechanism: Why Formwork Drilling Is Eliminated

Unlike fully threaded tie rods, which must pass through pre-drilled holes in the formwork and penetrate the concrete section, the operating mechanism of the strap bolt is fundamentally different. The strap bolt passes through the gap between two adjacent formwork panels and clamps their edges together. Using a simple yet extremely secure connection—pin and wedge—it locks onto the panel edges through the punched holes at both ends.

This process secures the opposing panels in a perfectly parallel alignment with a fixed and accurate spacing. Consequently, no holes are required in costly metal formwork panels, which represents one of the most significant advantages of this system.

Main Applications Beyond Shear Walls

While shear wall formwork is the most recognized application, the flexibility of strap bolts allows their use in other structural areas as well:

- Large-Section Columns: Suitable for restraining large rectangular column formwork where concrete pressure is substantial.

- Internal Foundations and Complex Slabs: In special designs, strap bolts are used to fix metal lath to beams and columns in multi‑level slab foundations.

- Non‑structural Applications: In limited cases, they may be used to secure fence bases or similar temporary installations.

Standard Technical Specifications: Zaman’s Commitment to Quality and Safety

Quality and safety in formwork operations directly depend on the technical specifications and standardization of components. A non‑standard strap bolt may lead to severe incidents such as formwork blowout. Fully aware of this responsibility, Zaman Company manufactures its products using premium raw materials and strict technical criteria.

| Technical Parameter | Zaman Standard | Description |

|---|---|---|

| Steel Grade | ST37 Mobarakeh Steel (Hot‑Rolled Black Plate) | High‑quality steel ensures superior tensile strength and long‑term durability under extreme concrete pressure. |

| Thickness | Minimum 2 mm (up to 2.5 mm available) | This thickness is the safety benchmark for resisting concrete pressure. Thinner plates are strongly discouraged. |

| Width | 25–30 mm | Provides sufficient contact area with formwork edges, preventing stress concentration and panel damage. |

| Length | 30–100 cm (5 cm increments) | Wide length range allows use in different wall thicknesses; custom lengths are also available. |

2 mm Thickness: The Safety Red Line in Formwork

The lateral pressure exerted by fresh concrete—especially near the bottom of walls—is extremely high. Insufficient strap thickness can result in elongation or rupture. Failure of a strap bolt during concreting leads to localized loss of restraint and can trigger a chain reaction causing panel deformation or complete blowout. Such incidents not only incur significant financial losses but also pose serious safety risks to on‑site personnel.

For this reason, Zaman Company strictly adheres to a minimum thickness of 2 mm as a non‑negotiable safety standard, ensuring adequate resistance to both dynamic and static concrete loads.

Key Advantages of Strap Bolt Systems: Beyond a Simple Connection

Significant Increase in Execution Speed

The most tangible advantage of strap bolts is the dramatic increase in formwork installation speed. Time-consuming steps such as panel drilling, tie‑rod installation, sleeve placement, and nut tightening are completely eliminated. Each strap is installed simply by positioning it between the panels and locking it with a pin and wedge—a process that takes only seconds.

Cost Optimization: Direct and Indirect Savings

- Direct Cost Reduction: The need for secondary accessories such as tie rods, wing nuts, washers, sleeves, and spacers is eliminated.

- Indirect Cost Reduction: Faster execution reduces labor and overhead costs, extends the service life of formwork panels, and eliminates surface repair work.

Flawless Exposed Concrete Surface and Enhanced Durability

Strap bolts produce perfectly smooth, hole‑free concrete surfaces—ideal for architectural exposed concrete applications—and improve long‑term durability by eliminating potential moisture penetration points.

Engineering Precision and Dimensional Accuracy

Fixed strap lengths ensure precise wall thickness throughout, prevent panel bulging, and result in plumb, dimensionally accurate concrete walls.

Selection and Installation Guide

Correct strap length selection and proper installation are essential to fully benefit from the system.

Strap Length = Wall Thickness + (Edge Width of Panel 1 + Edge Width of Panel 2)

5 cm edge panels: Strap length = Wall thickness + 10 cm

6 cm edge panels: Strap length = Wall thickness + 12 cm

Step‑by‑Step Installation Instructions

- Preparation: After reinforcement and spacer installation, set the first row of panels.

- Initial Placement: Install the first strap approximately 25 cm above the base.

- Vertical Spacing: Reduce spacing in lower zones due to higher pressure.

- Final Row: Install the last strap 25 cm below the top edge.

- Completion: Continue horizontally until the wall is fully formed.

Comparative Analysis: Strap Bolt vs. Fully Threaded Tie Rod

Despite reusability, traditional tie‑rod systems are less economical when considering total installed cost and project impact. Strap bolts clearly outperform tie rods in speed, cost efficiency, surface quality, and structural integrity.

Quality Assurance and Safety Considerations

Selecting standardized, high‑quality strap bolts is essential for site safety and performance. Zaman Company ensures transparency in material quality, dimensions, and manufacturing control.

The Strap Remains Inside the Concrete

After formwork removal, the strap remains embedded in the concrete. Protruding ends are easily broken or ground flush, eliminating the need for deep hole repairs and preserving structural continuity.

Conclusion: Zaman Strap Bolt—A Smart Investment in Project Efficiency

Transitioning from traditional systems to strap bolt technology is not an expense, but a strategic investment in efficiency, quality, and profitability. Zaman strap bolts deliver unmatched speed, lower total cost, and superior concrete surface quality—making them the trusted choice for modern concrete construction projects.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.