Prop Removal Timing for Joist Block Ceilings

In the realm of modern construction, the timing for removing props under joist block ceilings is one of the most critical and decisive stages in the execution process of concrete ceilings. This article provides a comprehensive examination of this issue, focusing on Iranian standards, influencing factors, guideline tables, and practical tips. The props beneath the joist block ceiling serve as temporary supports and play a key role in maintaining structural stability; improper removal can lead to serious problems such as cracking or even collapse. At ZemanCo, by offering high-quality products and professional services, we assist engineers and contractors in managing this process optimally.

Understanding the Concept of Props Under Joist Block Ceilings

The operations of concrete formwork and shoring are among the most vital and complex stages in the reinforced concrete construction process. This stage, acting as a temporary structure, holds the fresh concrete in place and gives it the desired shape until it sets. The joist block ceiling is one of the most common ceiling systems in residential and commercial buildings in Iran, consisting of concrete or precast joists, cement blocks, and a top concrete layer.

Props provide essential support for horizontal elements such as ceilings and beams, bearing the weight of fresh concrete as well as subsequent structural loads. “Prop removal,” meaning detaching these supporting members from under the ceiling after concrete pouring, is not merely an operational step but a decision that directly affects the entire structure’s strength, durability, and service life. Failure to adhere to the precise timing and standards can result in severe consequences including cracking, permanent deformation, abnormal shrinkage, and even structural failure.

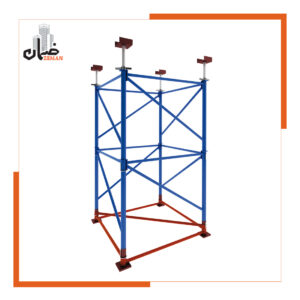

The props under the joist block ceiling, often in the form of metal jacks or safety stands, are indispensable for bearing the weight of fresh concrete until complete curing. The timing for removing these props must be calculated precisely to ensure the safety of the structure. According to Iran’s National Building Regulations, this timing is determined based on concrete strength. At ZemanCo, we provide various types of simple ceiling jacks compatible with high standards for this purpose.

In the construction process, props beneath the joist block ceiling not only provide mechanical support but also aid in uniform load distribution. This importance increases when early removal of props can result in high repair costs. For example, in large projects, advanced systems such as triangular scaffolding can complement the props and enhance safety.

The main objective of this article is to provide a scientific and practical approach to determine “the appropriate time for removing props under joist block ceilings.” Despite its seemingly simple nature, this question has a multifaceted answer that requires careful understanding and analysis of standards, technical factors, and quality control methods. While project managers usually prefer to complete the work faster to shorten the construction cycle, concrete engineers and specialists consistently warn that premature prop removal is one of the leading causes of formwork system failures and structural weaknesses. Therefore, the timing must be based on specialized data and criteria rather than guesswork.

In the following sections, we examine various standards (IS, ACI, BS), factors affecting concrete hardening (including cement type and temperature), reliable methods to confirm concrete strength, and safety principles during prop removal operations. The goal is to empower engineers, contractors, and project managers to make accurate and evidence-based decisions regarding prop removal timing. This study is fully based on internationally recognized standards such as the American Concrete Institute (ACI) and British Standards (BS), with all information verifiable and credible. Join us to explore this crucial construction topic in detail.

International and Local Standards for Prop Removal Timing

Determining the correct time for removal of props and other formwork elements, rather than relying on personal experience or local trade practices, is extensively defined under “Formwork Stripping Times” in concrete engineering standards. These standards, developed through extensive research and testing, specify conditions and requirements for each structural element to ensure overall safety and integrity.

In Iran, the National Building Regulations (Chapter 9) and the Iranian Concrete Code (ACI equivalent) provide explicit standards for the removal timing of props under joist block ceilings. According to these regulations, for joist block ceilings, the prop removal time should not be less than 7 days under ideal conditions. For special cases such as seismic-prone structures, this duration can extend to 28 days. Key related standards include IS 456:2000, ACI 347, and BS 8110, which are reviewed further below.

The Indian Standard IS 456:2000 gives important recommendations for joist block ceilings. It states that for slab ceilings without props, the minimum stripping time is 14 days after concreting, while with props, it is reduced to 7 days. For ceilings with spans longer than 4.5 meters, the stripping time remains 14 days without props and 7 days with props. This standard also emphasizes that these durations apply to Ordinary Portland Cement (OPC) at average temperatures (~27°C), and adjustments should be made when other cement types are used.

The American Concrete Institute (ACI) standards, particularly ACI 347, are among the most authoritative global references and provide comprehensive guidelines in this area.

ACI 347.2R-17 specifically addresses the design and implementation of shoring and reshoring systems in multi-story buildings. It highlights the importance of analyzing construction loads and load transfer to lower floors, stating that props removal is safe only when concrete reaches sufficient strength to carry these construction loads.

ACI 347-04 (now a superseded guideline) emphasized in section 3.7 that formwork should only be removed when the concrete has achieved adequate strength to bear the intended design loads.

ACI 318 requires vertical formworks (such as columns and walls) to be removed after at least 12 hours, provided no damage occurs to the concrete. It also mandates that formwork removal should not be premature and that the concrete should have reached at least 70% of its specified compressive strength before stripping.

The British Standard BS 8110 also provides detailed guidance. According to BS 8110, the typical soffit removal time for horizontal elements like slabs and beams under normal temperature conditions is 7 days. For spans exceeding 6.7 meters, this period extends to 21 days.

| Standard | Element Type | Special Condition | Minimum Formwork/Prop Removal Time | Key Notes |

|---|---|---|---|---|

| IS 456:2000 | Joist Block Ceiling | Without Props | 14 days | For Ordinary Portland Cement at ~27°C |

| IS 456:2000 | Joist Block Ceiling | With Props | 7 days | Provided effective shoring |

| ACI 318 | Vertical Formwork (Columns & Walls) | Provided no damage to concrete | At least 12 hours | Concrete must achieve initial strength |

| ACI 347 / 347.2R-17 | Slabs and Beams | Curing and structural load bearing | ≥ 70% of design strength | Removal only after concrete strength confirmation |

| BS 8110 | Slabs and Beams (Span ≤ 6.7 m) | Normal temperature conditions | 7 days | Typical soffit removal time |

| BS 8110 | Slabs and Beams (Span > 6.7 m) | Long span | 21 days | To prevent excessive deformation |

As observed, although these standards differ somewhat in timing, they uniformly emphasize that formwork and prop removal is a process to be carried out carefully and depends on the project’s specific conditions. None provides an absolute fixed date but rather methods to determine the appropriate timing, which will be elaborated in subsequent sections.

Factors Influencing Concrete Hardening Rate and Prop Removal Timing

Research indicates that the timing for removing props under joist block ceilings depends on multiple factors, which can vary the range from 7 to 28 days, influenced by temperature, concrete type, and environmental conditions. Evidence shows that for maximum safety, concrete should achieve at least 70% of its 28-day design strength before props removal—a requirement emphasized in Iran’s National Building Regulations.

Due to technical complexities, colder conditions generally require longer curing times, while warmer climates accelerate the process. Experts recommend consulting engineers to avoid potential hazards.

Although debates exist on the exact timing, the majority of sources highlight the importance of controlling concrete strength gain and avoiding premature removal to prevent cracking or collapse.

Determining the precise time for prop removal is not standardized by a fixed date but should be based on actual project conditions and concrete strength attainment. None of the aforementioned standards prescribe a fixed removal date but provide methodologies to estimate proper timing. Concrete hardening speed and achieving design strength are influenced by a combination of factors discussed below. Hence, the answer to “When to remove props?” must be derived from the question: “What percentage of required strength has the concrete gained?”

Ambient Temperature

The first and most critical factor is ambient temperature, which plays a key role in the cement hydration chemical reaction rate. At higher temperatures, this reaction is faster, and concrete gains strength sooner. For example, at 80°F (about 26.7°C), concrete can reach 89% of its 28-day strength after 7 days, whereas at 40°F (about 4.4°C), it only reaches 49%. This directly affects removal timing. In hot summer conditions, prop removal may occur earlier than normal standards, but in colder winter conditions, it may significantly extend to 10–14 days or more. Low temperatures also increase the risk of rebar corrosion; thus, chloride-free accelerators are sometimes used.

Type of Concrete and Cement

The second factor is cement type. Portland cement is classified into various types, each with different setting and hardening characteristics.

- Ordinary Portland Cement (Type I or OPC): Standards are often based on this type, defining normal timing.

- Rapid Hardening Cement (Type III): Due to higher surface area of its particles, it reacts fastest and can reduce prop removal time to as little as 3 days.

- Low Heat and Sulfate Resistant Cement (Types IV & V): Designed for large-scale projects and mass concrete works with high heat generation; these set more slowly, thus require longer removal times, about 14 days or more.

- Pozzolanic Cement (Type II, PPC, PSC): These cements harden slower than OPC and need 1.4–1.7 times longer duration for prop removal than OPC.

Water-Cement Ratio

The third factor is the water-to-cement (w/cm) ratio and use of admixtures. Lowering w/cm ratio and using additives such as silica fume or polymer resins can enhance early concrete strength, indirectly shortening prop removal time. Accelerating admixtures can reduce removal time to 2–3 days for ceilings but may decrease final concrete strength.

Furthermore, climatic conditions like humidity affect curing time. In humid areas, removal timing may extend to 14 days or more.

Concrete Curing Method

Finally, the concrete curing method significantly impacts the process. Proper curing means maintaining suitable moisture and temperature in the concrete until adequate strength is achieved. Using polyethylene covers or keeping the concrete surface moist improves ultimate strength, while poor curing causes uneven drying and weakens the structure.

Concrete Volume and Ceiling Height

Concrete volume and ceiling height also matter. Larger concrete volumes increase the time to reach sufficient strength before prop removal. Thick sections like columns and walls, which dissipate heat better, may also require longer hardening times. Thin, wide elements such as ceilings harden faster because of higher surface-to-volume ratio.

Therefore, precise timing for prop removal should not rely solely on a single standard or simple assumption. A combination of ambient temperature, cement type, element dimensions, w/cm ratio, and curing method must be considered. This multivariate analysis mandates a dedicated removal timing plan for each project.

Reliable Methods to Confirm Concrete Strength Before Prop Removal

Since prop removal timing depends on actual project conditions and cannot rely on a fixed value, reliable methods have been developed to evaluate and confirm sufficient concrete strength prior to removal. These techniques enable engineers and site supervisors to make accurate, scientific decisions and avoid consequences of premature removal. They mainly fall into two categories:

- آزمایش های مخرب (Destructive Tests)

- آزمایش های غیرمخرب (Non-Destructive Tests).

Testing Concrete Cube or Cylinder Samples (Cylinder/Cube Test)

This traditional and fundamental method evaluates concrete strength. In this technique, after pouring concrete on site, standard samples (cubes of 15x15x15 cm or cylinders with 15 cm diameter and 30 cm height) are taken from the same concrete mix. These samples are typically cured under laboratory conditions, but to ensure precise accuracy, additional samples are cured under conditions simulating the actual site environment (such as ambient temperature, humidity, wind, and direct sunlight). After various curing durations (e.g., 3, 7, 14, and 28 days), these samples are compressed in a vertical press to measure their compressive strength. When the strength of site-cured samples reaches the minimum specified in the design documents or technical specifications (for example, 75% of the 28-day strength), this condition is considered suitable for prop removal. This method, also known as the “Maturity Method,” is especially important in large and critical projects. Simply put, it is based on the principle that concrete cured under the same conditions exhibits similar strength, so samples poured simultaneously and in identical environmental conditions can represent the status of the main structural element.

Utilizing the Concrete Maturity Method

This is a more advanced technique than traditional sampling. In this method, wireless sensors (such as SmartRock®) are placed inside the formwork to continuously monitor the concrete temperature over time. These data, combined with strength versus time data for the specific concrete mix, are transmitted to a device that calculates and displays real-time concrete strength via an algorithm. This approach enables continuous and precise concrete performance monitoring and significantly reduces errors related to laboratory conditions by relying on real-site data. Not only does this system optimize the timing for prop removal, but it also saves time and costs by permitting removal at the exact right moment rather than adhering to a generalized fixed time.

Non-Destructive Tests (NDT)

This group of methods assesses concrete properties without damaging it and is especially useful where cube testing is infeasible or avoided.

Ultrasonic Pulse Velocity Test (UPV)

This method is based on the principle that ultrasonic pulse waves travel faster through sound, high-strength concrete. By measuring the time these pulses take to pass through the concrete, information about density, crack formation, and overall concrete integrity can be obtained.

Rebound Hammer Test (Schmidt Hammer)

This test evaluates surface hardness by measuring the rebound distance of a spring-loaded mass impacting the concrete surface. Surface hardness correlates inversely with compressive strength. It is a quick and simple method to perform a rapid preliminary strength assessment.

Testing Control Samples

If control samples are prepared on-site, their strength can be used to ensure concrete condition, provided the samples are cured under conditions reflecting the most severe curing environment on-site.

Engineer Approval and Consultation with Concrete Supplier

Ultimately, no testing method replaces the expertise and supervision of a structural engineer. Before any action, the engineer must issue final approval by consulting with the concrete supplier and considering project-specific conditions. Suppliers generally hold detailed information about their concrete mix performance under various conditions and can offer precise recommendations for optimal prop removal timing. Additionally, the engineer’s skill and experience in visual inspection (checking for the absence of surface moisture, adequate stiffness, and no cracking) are integral to decision making.

Consequently, rather than relying solely on a standard table, it is best to combine these methods within the project. Initial estimates may use standard tables, but ultimately, site-cured cube tests or intelligent sensors combined with final engineer approval should determine the prop removal timing. This integrated approach guarantees structural health and minimizes risks related to premature prop removal.

Execution Cycle and Safety Procedures for Prop Removal Operations

Removing props and concrete formwork is a cyclical process requiring systematic sequencing and high precision. This process generally comprises three main stages:

- Removal of vertical formwork

- Removal of horizontal formwork

- Then removal of supporting props.

This execution order corresponds to the way loads are distributed in the structure.

The first priority is removing vertical formworks such as walls and columns, since these elements naturally bear lateral loads and transfer their weight down to the foundation system; hence, their side formworks can be stripped earlier.

The second stage is removing horizontal formwork covering slabs or beams. This should occur only when the concrete has hardened sufficiently to bear its own weight plus temporary additional loads (such as workers and construction materials) without deformation or damage. Extreme caution is required here because slabs and beams are subject to bending, and their instability can cause serious consequences.

Finally, the third stage is the removal of props. This should only be done once the concrete attains enough strength to carry the loads imposed by upper floors without permanent deformation. Generally, the sequence is:

- Removal of side formworks for walls and columns (24 to 48 hours after pouring concrete).

- Removal of horizontal formwork (floor slab) at the appropriate time (typically 3 to 7 days).

- Removal of supporting props at the final appropriate time (usually 7 to 21 days, depending on the span of the structure).

Safety Measures

More important than execution order is ensuring safe execution. Safety measures in formwork and shoring are critically important. Premature formwork removal can cause structural collapse and endanger workers. Key safety procedures include:

- Regular inspections: Conduct systematic inspections before, during, and after concrete pouring to ensure all formwork and scaffold components are properly tightened and free from distortion or damage.

- Compliance with safety standards: Use safety equipment like safety nets, toe boards, and adhere to OSHA regulations and local building codes. The use of quality materials and adjustable support systems such as ceiling jacks and modern scaffolding systems is essential for safety and stability.

- Use of appropriate tools: Avoid metal tools (like hammers) during formwork stripping that could damage concrete; instead, use wooden tools such as wooden nail guns.

- Recycling and reuse of formwork (Cycling Formwork): Recycling formwork systems not only offers economic and time benefits but also reduces resource consumption.

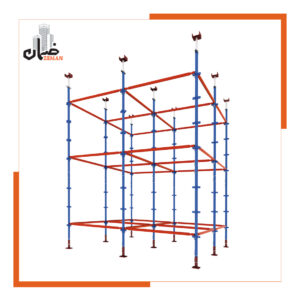

In practice, formwork removal may be phased. For instance, in multi-story buildings, after removing formwork from floor A and installing temporary shores underneath, these shores must remain until concrete reaches final strength. This procedure, called “reshoring,” is widely used in high-rise construction. It prevents excessive load transfer from upper floors to lower floors immediately below, ensuring structural safety throughout construction. According to ACI 347.2R-17 guidance, this method is vital for construction safety. If the concrete lacks sufficient strength, additional support systems or backshores can be applied at the pour strip or when strength issues arise. Should concrete bear greater loads than its capacity, support systems (Reshores) must be installed.

Additionally, using release agents before concrete pouring facilitates formwork removal and prevents damage to the concrete surface. The fundamental principle is that formwork and props should only be removed once the supervising engineer confirms the concrete has attained adequate strength to support its own and any applied loads. This principle is the ultimate goal of all evaluation methods. As a result, execution must be coordinated, careful, and technically approved to ensure structural safety and quality.

Impact on Construction Cycle and Role of Professional Equipment in Precise Execution

Deciding the timing for prop removal has widespread implications on the construction cycle and ultimately the project’s cost and schedule. Timely prop removal is recognized as one of the best methods for optimizing the construction cycle. This choice returns input costs such as jacks, scaffolding, and labor in a cyclic manner, allowing other construction activities to proceed quickly. This directly reduces transportation, installation costs, and, consequently, the total project cost. Conversely, premature prop removal can cause undesirable outcomes like cracking, excessive deformation, costly repairs, and in extreme cases, structural collapse, resulting in project delays, unforeseen costs, and legal liabilities. Therefore, balancing construction speed and structural safety is the key to success.

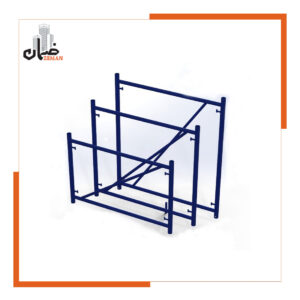

In this balance, the role of professional, high-quality equipment is vital. Selecting suitable products for formwork and shoring not only facilitates precise and safe execution but also directly influences removal timing. For example, steel formworks, due to their reusability and manufacturing precision, provide higher accuracy during execution. Among your product range, concrete wall formworks, round column formworks, and foundation formworks can be introduced as systems that optimize concrete pouring and curing times. These formworks, with their high manufacturing precision and strength, ensure requisite conditions for concrete curing and thus allow more accurate determination of prop removal timing.

Furthermore, customized scaffolding systems and jacks play a central role in precise prop removal operations. Hammerhead scaffolding or H-frame scaffolding can serve as primary shores within the structural system.

However, during removal, selecting the appropriate supportive jacks and scaffolding is critical. Simple ceiling jacks or wall and column support jacks allow precise height adjustment post-concrete pouring. This enables concrete to support its own load at earlier ages (e.g., after 3 days), after which initial props can be removed and supporting jacks (reshoring) maintain load transfer to lower floors. This method, extensively recommended by ACI 347.2R-17, requires scaffolding and jacks capable of fine and accurate adjustment.

U-head jacks (U jacks) serve as temporary, high-precision load-bearing tools. These products facilitate precise reshoring implementation and significantly reduce execution risks. Choosing quality, certified ZemanCo products not only eases advanced reshoring methods but also ensures concrete strength test results align more accurately with standards. With reliable scaffolding and support jacks, early removal of initial props can be confidently undertaken to accelerate the construction cycle.

Additionally, modular formwork systems such as modular steel formwork or ECO ceiling formwork impact the overall process. Due to their lightness, fast installation and stripping times, and geometric precision, these systems reduce formwork execution time, allowing engineers and laborers to advance quickly to the next stage (curing and removal). Their precise design optimizes stresses induced in concrete and prevents structural defects.

Ultimately, using professional equipment such as high-quality plywood formworks, scaffolding, and certified jacks increases construction efficiency. This means the construction team can focus more time on other activities, while precise support systems ensure the structure remains safe and sound throughout the construction cycle. Therefore, investing in quality equipment is a strategic investment enhancing both productivity and project safety and quality.

The Importance of Props Under Joist Block Ceilings

Props under joist block ceilings play a vital role in supporting the structure during concrete pouring. These temporary elements bear the weight of fresh concrete and prevent deformation of the ceiling. Timely removal of these props not only assures safety but also helps optimize project costs and schedule. At ZemanCo (zemanco.com), we provide quality products such as ceiling jacks to facilitate this process.

Main Influencing Factors

Several factors affect the timing of prop removal under joist block ceilings. Ambient temperature is among the most critical: at lower temperatures, concrete setting slows down, requiring longer time before props can be removed. Cement type and additives also alter this timing; for example, rapid-setting cements accelerate the process.

Safety Recommendations

Always verify concrete strength with standardized tests before removing props. Avoid sudden removal and perform the process gradually. ZemanCo offers free consultation services to help select the best props for joist block ceilings to ensure safe and efficient project progress.

The Influence of Concrete Strength on Removal Timing

Concrete compressive strength is the key criterion for determining the timing of prop removal under joist block ceilings. According to the Iranian Concrete Code, concrete must attain at least 70% of its 28-day strength before props can be removed. This strength is measured through testing concrete samples. For instance, if the 28-day strength is 25 MPa, a minimum of 17.5 MPa should be achieved. In sensitive projects, it is recommended to use modular steel formwork compatible with joist block ceiling props.

Conclusion: Why Choose ZemanCo?

Determining the correct time for removing props under joist block ceilings requires technical knowledge and quality equipment. By selecting ZemanCo products, you not only ensure your project’s safety but also benefit from expert consultation and competitive pricing. We invite you to visit the ZemanCo website to place your orders.