Precast Concrete Foundations (or Ready-Made Footings)_Types and Applications

The origins of precast concrete foundations date back to the early 20th century, when engineers, seeking to accelerate construction following the world wars, turned toward factory-based production. In Iran, this method was introduced in the 1970s through major government projects such as dam construction and industrialized building.

Today, due to population growth and the need for rapid housing development, ready-made foundations have become a necessity. According to reports by the Iran Concrete Association, the use of this method can reduce overall project costs by 20–30%, as it minimizes downtime at the site. Nevertheless, its importance is greater in earthquake-prone regions such as Tehran, where factory‑produced concrete can enhance seismic resistance.

Precast foundations or reinforced concrete foundation beams are solutions that can make the workflow at construction sites faster and simpler. In the following, you will learn in which types of projects these foundations are typically used and what considerations must be taken into account when ordering them.

What Is a Precast Concrete Foundation?

A precast or ready-made foundation consists of concrete elements produced in a factory and then transported to the project site. This method reduces construction time and offers higher quality, although it may involve higher initial costs. This contrasts with traditional foundations, where concrete is cast in place. The term “ready-made foundation” is often used to emphasize its factory-prepared aspect. Key components include:

- High‑grade concrete (typically 300–400 kg of cement per cubic meter)

- Steel reinforcement bars

- Sometimes additives such as superplasticizers to increase durability

This method is designed based on international standards such as ACI 318 (American Concrete Code) and Iran’s National Building Regulations. Producing such components requires precise molds — Zeman Co., with more than 30 years of experience, supplies various welded and pressed metal formwork systems. For more information, visit the page for all concrete formwork equipment.

Types of Precast Concrete Foundations

Precast concrete foundations are categorized according to shape, application, and load-bearing characteristics. Below are details for each type based on industry standards:

Strip Foundations

This type is suitable for buildings with uniform loads such as load-bearing walls. Reinforced concrete strip elements are manufactured in the factory and connected on-site using mechanical or adhesive joints. The typical width is 40–60 cm and the depth 50–100 cm, adjustable depending on the building load.

In traditional methods, these walls are constructed using double-sided wall formwork. However, where access is limited to one side, the single-sided formwork technique is used. In Iranian residential projects, this type is common and can be reinforced using concrete with compressive strengths above 30 MPa.

- Advantages: Uniform load distribution and fast installation.

- Applications: Low-rise buildings and retaining walls.

Modular Concrete Blocks

Precast blocks that interlock like Lego pieces, allowing easy expansion. Ideal for small foundations or adjustable projects. Their compressive strength is usually above 25 MPa, and they can be reinforced with steel bars.

- Advantages: High flexibility and low maintenance cost.

- Applications: Gardens, landscaping, and temporary buildings. In Iran, also used for fencing.

Pad or Point Foundations

Used for individual columns, typically square or rectangular with dimensions of 1–3 meters. In bridge construction, this type is strengthened with prestressing to increase tensile capacity.

- Advantages: Concentrated load bearing and reduced concrete volume.

- Applications: Columns of commercial buildings, bridges, and lighting poles.

- Specifications: Often produced with prestressed concrete and anchor bolts.

Prestressed Foundations

Reinforced with prestressed steel cables for increased resistance to tension and bending. Suitable for seismic regions where, according to Iran’s 2800 seismic code, this type is recommended.

- Advantages: Reduced cracking and improved vibration resistance.

- Applications: High‑rise buildings and high‑risk areas.

- Specifications: Prestressing stress typically 1000–1500 MPa.

Precast Pile Foundations

Concrete piles produced in factories and driven into the ground using pile-driving hammers. Ideal for weak soils and capable of penetrating depths up to 20 meters.

- Advantages: Transfers loads to deeper soil layers.

- Applications: Buildings on soft soil, bridges, and marine structures.

- Specifications: Diameter 30–60 cm with variable length.

In addition to these main types, specialized foundations such as those for lighting poles (3–9 meters), camera towers (cubical, tubular, or modular), greenhouses (for wind and rain protection), and fencing (in steel or concrete) are also widely used in Iranian urban and industrial projects.

For producing these types, special molds are required, which Zeman provides through customized design. See the page for special molds.

The table below compares the types of precast foundations:

| Type of Foundation | Main Application | Advantages | Challenges | Approx. Cost (Toman/m²) |

| Precast Strip | Residential buildings | Fast installation, low cost | Requires strong connections | 500,000 – 800,000 |

| Modular Blocks | Small projects | Flexible | Load limitations | 400,000 – 600,000 |

| Pad (Point) | Industrial columns | Load concentration | Difficult to transport | 600,000 – 1,000,000 |

| Prestressed | Seismic zones | High resistance | Advanced technology | 800,000 – 1,200,000 |

| Precast Piles | Weak soil | High depth | Requires heavy equipment | 700,000 – 1,100,000 |

Applications of Precast Foundation Beams in Industrial Construction

- In large industrial buildings with skeletal structures, foundations are used at ground level as foundation walls to enclose the building perimeter.

- The surface quality of the foundation depends on investor requirements and can be produced using architectural concrete technologies to achieve smooth or washed textures.

- Reinforced concrete foundation beams are produced based on the project’s plans, and their dimensions are always determined according to the project’s needs. Typically, maximum lengths reach 7 meters and heights reach 2 meters.

- Foundation beams can be produced in single-layer form (requiring insulation on-site) or multi-layer form incorporating insulating materials such as expanded polystyrene, Styrodur, PIR/PUR foam, or mineral wool. Multilayer structures can be manufactured with various thicknesses according to investor needs.

Precast Concrete Foundations

- If foundations are to be placed on footings, required notches and projections are built according to plan. Similarly, openings required for doors or gateways are incorporated during the precast stage. These foundations are often equipped with metal fittings to protect the edges of precast elements.

- In addition to metal fixtures, precast foundations can be equipped with system accessories such as corrugated conduits, anchor rails, and lifting hooks to facilitate connection with other structural components.

- The installed foundation must be protected with a moisture-resistant membrane.

Precast Foundations in Road Construction

- In road construction, precast foundations are typically used as bases for sound barriers, whether along highways or railways.

- Reinforced concrete foundation beams are installed beneath sound panels and serve as the first structural layer on which acoustic walls are mounted. These beams are positioned between steel or reinforced concrete columns, with dimensions defined by design plans. Typically, modules are produced in lengths of 2, 3, 4, or 5 meters. For easier installation, foundations are equipped with appropriate connectors and lifting hooks.

Precast Foundation Beams

- The use of precast elements is becoming increasingly common not only in industrial construction but also in large-scale and even residential projects.

- The use of precast slabs, balconies, or staircases has become very common in residential construction. For industrial projects, we offer comprehensive solutions for precast walls and load-bearing roof structures.

Advantages of Using Precast Foundations

A precast concrete foundation can reduce project duration by up to 50% because on-site concrete casting is eliminated. This method is also environmentally friendly as it generates less waste.

One of the biggest advantages is installation speed. In traditional projects, foundation casting may take weeks, whereas precast methods reduce this to the minimum possible time. Furthermore, factory quality control is superior, as compressive, tensile, and flexural strength tests are performed regularly. Environmentally, this method reduces concrete waste by up to 40%, thanks to controlled production conditions.

In Iran, where challenges such as water scarcity persist, this method is beneficial as it reduces water consumption at the site. Additionally, labor costs decrease because fewer skilled workers are required on-site — an important economic advantage compared with the cost of erecting complex scaffolding systems such as Cuplock or Omega triangular shoring for in-situ construction.

At Zeman, using advanced machinery such as automated welding, we have a daily production capacity of more than 20 tons of concrete formwork, facilitating the production of ready-made foundations. However, the advantages are not absolute; in remote areas, transportation costs may increase. To compensate, it is recommended to use modular elements for easier transport.

Key Considerations for Selecting and Installing Foundations

- Before selection, soil testing must be performed. Installation typically requires cranes and secure fastening. Given Iran’s diverse climate, moisture-resistant types are recommended.

- Precast or ready-made concrete foundations are one of the key innovations in modern construction, especially in countries like Iran, where there is a high demand for rapid infrastructure development.

- Zeman Company, as one of the leading manufacturers of concrete formwork systems in the Middle East, plays a major role in facilitating the production of such foundations. For example, our bent and strap metal molds can be used in producing precast elements.

Challenges and Limitations of Precast Foundations

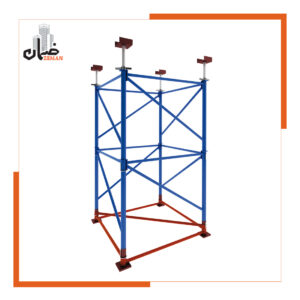

Despite the numerous advantages, challenges such as the need for heavy cranes during installation exist. In addition to cranes, temporary support structures sometimes must be erected using roof and support jacks and precisely adjusted using alignment jacks. If the initial design is incorrect, on-site correction becomes difficult. In Iran, due to sanctions, accessing high-quality raw materials such as premium cement may be challenging, but companies like Zeman mitigate some of these issues by importing materials such as plywood and wooden beams for formwork.

Types of Precast Foundations by Application and Structure

Precast foundations are categorized based on their final application and structural characteristics. Understanding this classification helps determine the optimal option for each project.

1. Classification by Application

Foundations for Vertical Structures

These form the most common category of ready-made foundations, designed to withstand vertical loads and overturning forces.

- Lighting poles and high-mast towers: The most widely used precast foundations, installed for lighting poles in streets, parks, stadiums, and open areas. These are engineered to resist wind loads and often include conduits for power cables. Standard dimensions exist for different pole heights.

- Telecommunication and camera towers: These structures require extremely high stability and minimal vibration. Their foundation design must account for wind and seismic loads to ensure proper operation of the mounted equipment.

- Flagpoles and urban structures: Similar to lighting-pole foundations but with specific structural or aesthetic requirements for urban applications.

Foundations for Linear Structures

- Fence and enclosure bases: Used to provide security around military zones, industrial sites, agricultural lands, and gardens. Fast installation along long distances and sufficient stability are critical advantages.

Special Foundations

- Greenhouse structures: These foundations provide a level and stable base for greenhouse frames and resist uplift forces caused by wind.

- Prefab and modular buildings: Used as single or strip foundations for modular building installations. Dimensional accuracy is vital to ensure proper module alignment.

2. Classification by Structure and Material

Plain and Reinforced Concrete

- Plain concrete foundations (without reinforcement) are suitable for very light loads such as small signs. However, the predominant type is reinforced concrete, strengthened using rebar mesh to withstand heavy loads.

Heel-type Foundations

This type features a wider bottom section (heel) that increases soil contact and significantly enhances resistance against overturning moments. It is ideal for tall and slender structures such as high-mast lighting towers or poles in windy and seismic regions.

Composite Foundations

These foundations combine precast concrete elements with structural steel components. They are used for specialized applications requiring very high load-bearing capacity and fine adjustment during installation.

Steel and Fiberglass Foundations

These two represent special options for extraordinary conditions. Steel foundations are lighter and more suitable for soft soils. Fiberglass foundations exhibit exceptional corrosion resistance and are used in chemically aggressive environments such as petrochemical facilities.

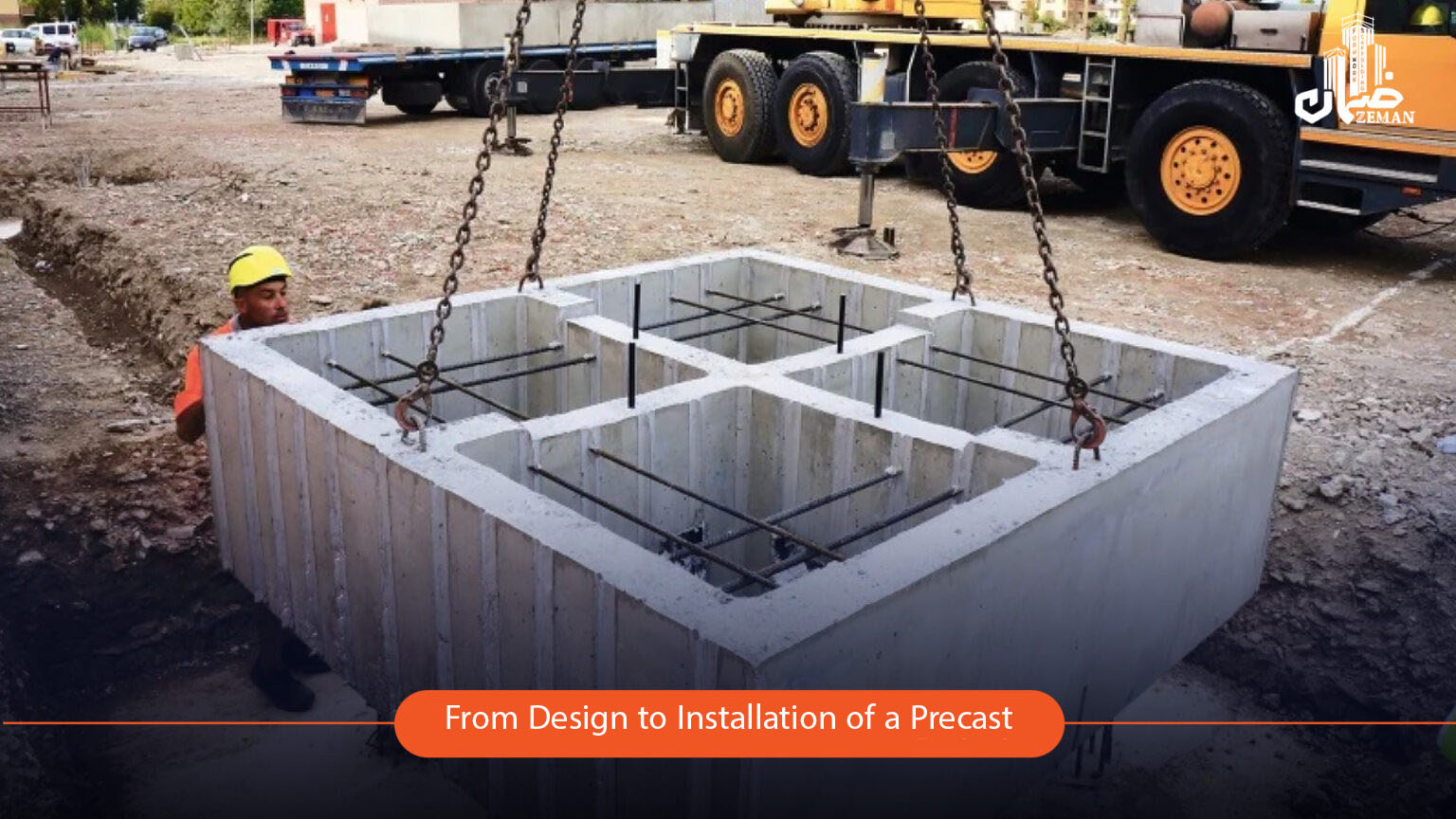

From Design to Installation of a Precast Foundation

- Factory production begins with CAD design, followed by formwork preparation using Zeman metal molds (20‑ton daily capacity). Concrete is poured, vibrated, and cured (typically 28 days), after which components are tested.

- Installation includes transportation by truck, placement using a crane, and connection using mortar or bolts. Engineering supervision is essential. In Iran, ISIRI standards are observed.

The production and installation of a precast foundation involve two distinct stages: precise factory manufacturing and rapid on-site installation.

Production Process – Engineering Precision in the Factory

- Structural design and geotechnical analysis: The process begins with engineering design. Dimensions and specifications are determined based on loads from the superstructure, wind data, seismic conditions, and most importantly, soil bearing capacity obtained from geotechnical investigations.

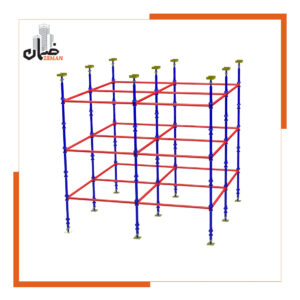

- Formwork design and preparation: This stage is the core of the production process and ensures the final quality. To achieve exact dimensional tolerances and repeatability, precision-engineered steel molds for precast elements must be used. For standardized shapes and high-volume projects, modular metal formwork systems are also applicable.

- Rebar cage assembly: Reinforcement bars are cut, bent, and tied according to structural drawings to form the rebar cage with high accuracy.

- Concrete casting, compaction, and curing: Concrete with a specified mix design is poured into the molds and compacted using internal or external vibrators to eliminate air voids. The element is then cured under controlled conditions (e.g., steam curing or immersion) to achieve the required strength in the shortest possible time.

High‑Efficiency Installation on Site

- Site preparation and excavation: The installation location is laid out according to the plans, and the trench is excavated with precise dimensions and depth.

- Transportation and handling: Heavy foundation elements are transported from the factory to the project site using carefully planned logistics and appropriate transport equipment.

- Positioning and leveling with a crane: Using a crane, the foundation is gently placed in the excavation and leveled accurately for the installation of the superstructure.

- Backfilling: The space around the foundation is filled with suitable soil or materials specified in the drawings and compacted layer by layer to fully secure the foundation.

Key Factors Influencing the Cost of a Precast Foundation

The price of a precast foundation is determined by several factors that help project owners estimate costs:

- Dimensions and weight: Directly affect material consumption (concrete and steel) as well as transportation and installation costs.

- Concrete grade and technical specifications: Using higher-strength or special types of concrete (e.g., self‑compacting or sulfate‑resistant concrete) increases production costs.

- Rebar complexity: Quantity, diameter, and complexity of reinforcement are major cost determinants.

- Number and type of anchor bolts: Their quantity, diameter, length, and coating impact the final price.

- Order volume: Large projects benefit from economies of scale, reducing the cost per unit.

A Solid Future with Precast Foundations

The shift toward industrialization and prefabrication is not a choice but an intelligent and inevitable response to the growing demands of modern construction. Precast concrete foundations, as a core component of this transformation, offer undeniable advantages in speed, guaranteed quality, safety, and cost optimization (in a holistic analytical framework).

It must be emphasized that all these advantages rest on one fundamental principle: precision in production. The quality of the final product reflects the quality of the tools and processes used to create it. Achieving the highest levels of quality and accuracy in precast elements depends on engineered formwork systems that form the backbone of the process. A precise foundation is born from precise formwork.

For expert consultation regarding the design and selection of formwork for your precast foundation projects — and to ensure compliance with the highest quality standards — contact the technical experts at Zeman Company.

Conclusion and Recommendations

Precast concrete foundations represent the future of construction, especially in Iran where speed and quality are essential. Zeman Company is ready to collaborate on custom production — contact us or visit our About Us page. Always consult an engineer for your projects.