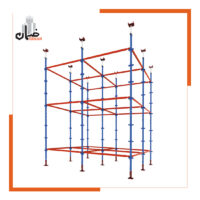

Safe and efficient access to height is the cornerstone of success in any construction project. Modern scaffolding systems, far more than temporary metal structures, serve as the operational backbone of projects, playing a vital role in everything from façade works and high-rise construction to bridge building and industrial facilities.

Selecting the correct type of scaffolding not only guarantees workforce safety but also has a direct impact on project progress speed and cost optimization. At Zaman Company, by offering a complete range of modular and standard scaffolding systems, we help you choose the most suitable and safest solution for your project. In this comprehensive guide, join us as we introduce the various types of scaffolding systems and the applications of each.

Showing all 6 results

What Is Scaffolding?

Scaffolding, also referred to as Scaffolding or Staging, is a temporary structure that allows individuals to stand on a stable platform in order to work at heights or in locations that are difficult to access.

These temporary structures are commonly used in the construction, maintenance, or repair of buildings, bridges, and other man-made structures, providing support for both workers and materials.

You can view the details of scaffold pricing and purchasing on this page.

Comprehensive Introduction and Review of Construction Scaffolding Systems

Choosing the right scaffolding system is a decision that directly affects the safety, speed, and final cost of your project. Each system, based on its unique design and engineering, is optimized for specific applications.

A knowledgeable engineer or contractor, by thoroughly understanding the different types of construction scaffolding and recognizing their key differences, can select the most suitable option for project requirements ranging from a simple residential façade to the most complex industrial structures.

In the following sections, we will thoroughly analyze the four main scaffolding systems and fully examine the features, applications, and technical details of each, enabling you to make the best decision with clarity and complete information.

Comparison of Modern Scaffolding vs. Traditional Scaffolding

One of the first and most important questions every contractor or project manager faces is choosing between modern (modular) scaffolding systems and traditional scaffolding (tube and coupler). These two approaches differ fundamentally in terms of speed, total cost, safety, and required workforce, and understanding these differences is essential for project optimization.

What Is Traditional Scaffolding (Tube and Coupler)?

This system, which has been used in Iran’s construction industry for decades, consists of two main components: steel tubes and connection couplers (right-angle, swivel, and others).

Main Advantage: Exceptional flexibility. This system can accommodate almost any complex geometric shape, from the façade of a historic building to unconventional structures.

Challenges: Heavy reliance on the skill and expertise of the installation team, slower assembly speed, and a higher potential for human error in fastening connections.

What Is Modern Modular Scaffolding (Hammer, Triangle, Cuplock)?

These systems are composed of prefabricated components with standardized dimensions and connections. The precise engineering of these parts allows for much faster and simpler assembly with inherently higher safety.

Main Advantage: Extremely fast installation, assured safety due to pre-engineered connections, and reduced dependence on highly skilled labor.

Challenges: Higher initial purchase cost for components and less flexibility compared to traditional systems when dealing with highly specialized and unconventional shapes.

| Feature | Modern Scaffolding (Modular) | Traditional Scaffolding (Tube & Coupler) |

|---|---|---|

| Assembly and Dismantling Speed | Very High | Low |

| Inherent System Safety | High (Standardized Connections) | Medium (Skill-Dependent) |

| Need for Skilled Labor | Low | Very High |

| Total Project Cost | Lower (Due to Time and Labor Savings) | Higher (Due to Time Consumption and Skill Requirements) |

| Flexibility for Complex Shapes | High | Very High |

| Optimal Application | Standard Construction Projects, Façades, Formwork | Special Structures, Spot Repairs, Historical Buildings |

Comparison Conclusion: For more than 90% of today’s construction projects, the advantages of modern scaffolding—particularly speed and safety—make it a far more economical and efficient option compared to traditional systems.

Smart Scaffolding Selection Based on Your Project Application

The best scaffolding system is the one that precisely matches your project’s needs. Instead of asking “Which scaffolding is better?”, ask “Which scaffolding is better for my job?”. Below, we introduce the best options based on common applications in the construction industry.

1. What Is the Best Scaffolding for Tall and Large Building Façades?

For façade scaffolding, speed and safety are the top priorities.

Primary Recommendation: Cuplock scaffolding. Due to its exceptional assembly speed, ability to cover large surfaces, and high connection safety, this system is the gold standard for high-rise and residential building façades.

Why? Vertical standards and horizontal ledgers quickly form a stable grid that provides safe working platforms across all levels.

2. Which Scaffolding Should Be Used for Heavy Concrete Slab Formwork?

The most critical factor in slab formwork or under-concrete scaffolding is load-bearing capacity.

Primary Recommendation: H-frame scaffolding. This system is specifically designed to تحمل extremely heavy vertical loads. Its frames efficiently transfer the weight of fresh concrete to the ground.

Why? Fast frame assembly combined with outstanding load-bearing capacity makes it the first choice for concrete slabs, bridge decks, and heavy ceilings.

As you can see, the world of scaffolding goes far beyond a simple choice. Each system was developed to solve a specific engineering challenge. Now that you are familiar with the general approaches and specialized applications of each system, you can more confidently review the scaffolding systems offered by Zaman Company in the next section and, by clicking on each one, explore the technical details of the product.

3. Which System Is Preferred for Industrial, Refinery, and Petrochemical Projects?

In industrial scaffolding, resistance to harsh environmental conditions, vibration, and flexibility for accessing complex areas are critical.

Primary Recommendation: Cuplock (Cup-Lock) scaffolding or Hammer scaffolding.

Why? The robust locking mechanism of Cuplock provides high resistance to industrial vibrations. Both systems, due to their modular nature, allow the creation of complex access platforms around pipes, tanks, and industrial installations.

Comparison Table of Scaffolding Systems

| Feature | Modern Scaffolding (Hammer / Cuplock) | Traditional Scaffolding (Tube & Coupler) |

|---|---|---|

| Assembly Speed | Very High | Low |

| Load-Bearing Capacity | High and Engineered | Medium (Execution-Dependent) |

| Flexibility | High | Very High |

| Inherent Safety | High (Standardized Connections) | Medium (Skill-Dependent) |

| Main Application | Façades, Industrial Use, Heavy Formwork | Complex Shapes and Repair Works |

Frequently Asked Questions About Scaffolding Systems

In this section, we clearly and accurately answer common questions that may arise for you as a specialist or project manager. Our goal is to provide information that supports better decision-making.

What Is the Main Difference Between Cuplock and Triangle Scaffolding?

The main difference lies in their design philosophy and specialized applications. Simply put:

- Triangle scaffolding is a vertical load-bearing specialist. Its entire design is optimized to تحمل extremely heavy loads in a single (vertical) direction, such as the weight of concrete slabs. Its structure consists of strong, simple frames ideal for creating wide, integrated load-bearing grids (formwork). This system is like a powerful weightlifter whose specialty is lifting extremely heavy loads.

- Cuplock scaffolding is a versatile and adaptable access system. Thanks to its locking cups, it allows connections in multiple directions and can easily adapt to complex geometries, curved façades, and industrial structures. This system is like a decathlete who performs exceptionally well across multiple disciplines (façades, industrial access, load-bearing scaffolding).

Summary: For heavy slab formwork, triangle scaffolding is the first choice. For façade scaffolding and complex three-dimensional access, Cuplock scaffolding is the optimal solution.

Are Modular Scaffolding Systems Suitable for Any Height?

In theory, yes—but this “yes” is conditional upon three critical principles: precise engineering design, proper anchoring to the structure, and strict adherence to load standards.

As height increases, lateral forces—especially wind load—become a decisive factor. A tall scaffold without proper anchoring can act like a sail and become extremely unstable.

Therefore, for high elevations, a structural engineer must determine exact anchoring intervals based on standards. Additionally, the quality and strength of components must fully comply with standards to withstand increased loads at lower levels.

Conclusion: Scaffolding at significant heights should never be erected without detailed engineering drawings and accurate calculations.

What Are the Most Important Safety Considerations When Working with Scaffolding?

Scaffold safety is a process that begins before installation and continues through dismantling. The key points can be categorized into three groups:

Pre-Work Measures:

- Daily inspection: All components, couplers, platforms, and connections must be inspected before each work shift by a qualified person.

- Ensuring a proper base: Scaffold bases must be placed on a level, firm, and stable surface. The use of adjustable base jacks and proper groundwork, when necessary, is mandatory.

Measures During Work:

- Full use of Personal Protective Equipment (PPE): Safety helmets, work shoes, and especially safety harnesses connected to a secure anchorage point are mandatory for all personnel working at height.

- Adhering to load capacity limits: Never place loads (materials, equipment, or personnel) exceeding the designed capacity on platforms.

- Using standard planks and platforms: Working platforms must cover the full width of the scaffold and be securely fixed.

General and Critical Rules:

- No unauthorized modifications: No one other than the responsible team is allowed to alter or move scaffold components.

- Work stoppage in adverse weather conditions: Working on scaffolding during strong winds, rain, or storms is strictly prohibited.

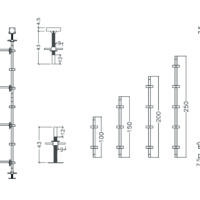

How Can I Calculate the Exact Quantity of Scaffolding Components Needed for My Project?

Accurately calculating component quantities is an engineering process that goes far beyond rough estimates. It requires specific input data:

- Exact structure dimensions: Length, width, and precise height of the area requiring scaffolding.

- Selected scaffolding type: Component types and quantities differ completely between hammer and triangle systems.

- Architectural and structural drawings: To identify obstacles, anchoring points, and applied loads.

- Number of simultaneous working levels: Determines how many working platforms are required.

Based on this information, a precise Bill of Materials (B.O.M) is prepared using specialized software or by technical experts. The best, fastest, and safest approach is to use the free consultation services of reputable companies. Our experts at Zaman are ready to perform these calculations accurately upon receiving your project details.

Does Zaman Company Also Provide Scaffolding Consultation and Design Services?

Yes. This is one of our core services and value propositions. We believe that selling scaffolding is complete only when accompanied by a comprehensive engineering solution. Our consultation and design services include:

- On-site project visits to gain a precise understanding of your execution needs.

- Expert consultation to select the most optimal and cost-effective scaffolding system.

- Designing detailed scaffolding execution drawings using engineering software.

- Providing a complete and accurate Bill of Materials (B.O.M) to prevent over-purchasing or shortages during the project.

Our goal with these services is to enhance safety, optimize costs, and accelerate the execution of your project.

One Step Away from a Smart Choice: Get Expert Consultation and Instant Price Inquiry

Selecting and implementing a scaffolding system is a critical investment in the safety and success of your project. Do not let technical complexities or unanswered questions prevent you from making the best decision.

Our team of technical experts and sales engineers at Zaman, with years of experience in diverse construction and industrial projects, is ready to share their knowledge with you. We stand by your side to help reduce costs and increase productivity through engineered solutions.

To get started, simply choose one of the following options:

Immediate Call: Call [+98 912 844 1055] and speak directly with one of our experts.

WhatsApp Message: Send a quick message to [+98 912 844 1055] to share your initial questions or request. You can also contact us anytime via WhatsApp through the support section, wherever you are.

Complete the Online Form: Fill out our short form at the link below. We will contact you within a few working hours and arrange a free consultation session for you.

Zaman Contact Form

What Happens After You Contact Us?

Free Consultation: Our expert will speak with you and carefully assess your project requirements.

Solution Proposal: The most suitable scaffolding system for your project will be recommended.

Transparent Quotation: A complete and transparent pro forma invoice, including a detailed list of components and pricing, will be provided.

We are not just a supplier; we are your partner in building a safe and sustainable future.