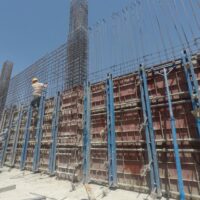

At first glance, the strength of a massive concrete structure appears to be the result of concrete quality and the resistance of reinforcing steel. However, experienced engineers and contractors know that another critical factor plays a decisive role even before a single cubic meter of concrete is poured: the concrete formwork system.

The stability, accuracy, and integrity of this temporary structure directly affect the quality, durability, and safety of the final concrete structure. At the heart of this system lies a collection of small yet vital components known as “formwork connections.” These connections are the unsung heroes that join, restrain, and secure steel panels against the enormous pressures exerted by fresh concrete. Without flawless performance of these components, even the most precise structural calculations and highest-quality materials become ineffective.

Showing all 14 results

Precise Definition of Formwork Connections

Formwork connections comprise a comprehensive set of components, tools, and mechanical mechanisms used for assembling, connecting, stabilizing, bracing, and integrating concrete formwork panels—whether steel, timber, or polymer-based.

The primary function of these components is to withstand forces applied during concrete pouring. The most significant of these forces is the hydrostatic pressure of fresh concrete, which tends to separate formwork panels and distort the intended geometry of the structure.

This system includes components for direct panel-to-panel connections (such as pins and wedges), elements for restraining double-sided formwork (such as tie rods), and accessories for connecting the formwork system to reinforcing bracing members (such as clamps).

Risk Analysis: The True Cost of Low-Quality Connections

Selecting formwork connections is not merely a procurement decision; it is a critical risk assessment. The use of non-standard, low-quality, or worn connections can lead to catastrophic consequences whose costs far exceed any initial savings. These risks include:

Formwork Bulging or Failure

Failure of a clamp or breakage of a nut can result in sudden formwork opening during concrete placement. This not only causes significant concrete loss but also compromises the final geometry of the concrete element.

Concrete Slurry Leakage

Weak connections—such as pins and wedges that do not fully tighten panels—allow cement slurry to leak through joints. This results in honeycombed, porous concrete surfaces with reduced strength, requiring costly repairs.

Serious Safety Hazards

Formwork failure can cause worker falls, flying components, and concrete collapse, directly endangering lives on the jobsite.

Project Delays and Cost Escalation

Any defect in formwork execution requires work stoppage, demolition of defective sections, re-forming, and re-pouring. This leads to significant increases in project duration and total cost.

Therefore, investing in high-quality, standard-compliant connections is not an operational expense but rather “project insurance.” Such investment reduces financial and safety risks while ensuring the final quality of the structure. Selecting a reputable supplier offering precise technical specifications and premium raw materials is the first and most critical step in effective risk management.

Comprehensive Breakdown of Formwork Connection Systems

Formwork connection systems include a diverse range of components, each designed for a specific function. Understanding their performance, technical specifications, and applications is essential for safe and accurate formwork execution. Below, these systems are categorized and analyzed based on their function.

Panel-to-Panel Connection Systems: The Core of Formwork Integrity

These connections are responsible for joining modular steel formwork panels together on flat surfaces or at corners.

Pin and Wedge

The pin-and-wedge system is considered the most fundamental, widely used, and cost-effective connection in modular steel formwork systems. It consists of two components: a pin (male) and a wedge (female).

Operating Mechanism

The connection mechanism is straightforward. The pin passes through the punched holes along the edges of two adjacent panels. The wedge is then hammered into the slot of the pin, locking it firmly in place and drawing the panels tightly together.

Key Technical Specifications

- Material: Typically manufactured from high-quality steel sheets such as ST37 to withstand hammer impact and applied loads.

- Thickness: Commonly produced in 3, 4, and 5 mm thicknesses. The 4 and 5 mm variants are the most durable and widely used.

- Dimensions and Weight: Pin length usually ranges from 9 to 9.5 cm, wedge length approximately 8.5 cm, with a standard pair weighing about 100–110 grams.

- Execution Guidelines: Depending on panel size and engineering judgment, approximately 8 to 16 pin-and-wedge pairs are used per square meter of formwork.

- Advantages and Limitations: High installation speed, very low cost, and ease of worker training are key advantages. Due to their small size, however, there is a risk of loss on site.

Clamps / Frog Clamps

Clamps serve as a more advanced and robust alternative to pin-and-wedge systems and are used where higher precision and strength are required.

- Applications: Ideal for connections requiring precise panel overlap and alignment. Commonly used in systems with frequent reuse such as tunnel formwork or precast wall systems.

- Material: Manufactured by casting from ductile (nodular) iron, providing exceptional resistance to tensile and compressive forces without brittleness.

Choosing between pin-and-wedge and clamp systems is a strategic decision based on project requirements. For standard foundations and walls, pin-and-wedge offers an excellent balance between cost and performance. For architectural concrete, watertight structures, or systems requiring millimeter-level accuracy, investment in ductile iron clamps ensures superior final quality and minimizes execution errors.

Formwork Connections: The Hidden Foundation of Durable Concrete Structures

Introduction: Beyond Steel and Concrete

At first glance, the strength of a massive concrete structure appears to result from the quality of the concrete and the strength of the reinforcing steel. However, experienced engineers and contractors know that another critical factor plays a decisive role even before a single cubic meter of concrete is poured: the concrete formwork system.

The stability, accuracy, and integrity of this temporary structure directly influence the quality, durability, and safety of the final structure. At the core of this system lies a set of small yet critical components known as “formwork connections.” These connections are the unsung heroes that connect, restrain, and secure steel panels, keeping them firmly in place against the tremendous pressures exerted by fresh concrete. Without the flawless performance of these components, even the most precise structural calculations and the highest-quality materials would prove ineffective.

Precise Definition of Formwork Connections

Formwork connections comprise a comprehensive range of components, tools, and mechanical mechanisms used to assemble, connect, stabilize, brace, and integrate concrete formwork panels, whether made of steel, timber, or polymer-based materials.

The primary function of these components is to resist the forces applied during concrete placement. The most significant of these forces is the hydrostatic pressure of fresh concrete, which tends to separate the formwork panels and alter the intended geometry of the structure.

This system includes elements for direct panel-to-panel connections (such as pins and wedges), components for restraining double-sided formwork (such as tie rods), and accessories used to connect the formwork system to reinforcing bracing members (such as clamps).

Risk Analysis: The True Cost of Low-Quality Formwork Connections

Selecting formwork connections is not merely a procurement decision; it is a critical risk assessment. The use of non-standard, low-quality, or worn connections can lead to catastrophic consequences, the costs of which far exceed any initial savings achieved through purchasing cheaper components. These risks include the following:

Formwork Bulging or Opening

A malfunctioning clamp or a fractured nut can result in the sudden opening of the formwork during concrete placement. This incident not only causes the loss of a significant volume of concrete but also compromises the final geometry and integrity of the concrete element.

Concrete Grout Leakage

Weak connections—such as pins and wedges that fail to tightly secure the panels—allow cement grout to leak through the joints. This phenomenon leads to honeycombed, porous concrete surfaces with reduced strength, requiring costly repair and remediation.

Occupational Safety Hazards

Failure of the formwork system may result in worker falls, the projection of components, and concrete collapse, directly endangering the safety and lives of personnel on site.

Project Delays and Cost Overruns

Any defect in the formwork system necessitates a halt in operations, demolition of defective sections, re-forming, and re-casting of concrete. This process significantly increases both the project duration and overall costs.

Therefore, investing in high-quality, standard-compliant formwork connections is not an operational expense but rather a form of “project insurance.” Such an investment mitigates financial and safety risks while ensuring the final quality of the structure. Selecting a reputable supplier that offers products with precise technical specifications and high-grade raw materials is the first and most critical step in effective risk management.

A Comprehensive Breakdown of Formwork Connection Systems

Formwork connection systems comprise a diverse range of components, each designed for a specific function. Understanding the performance, technical specifications, and applications of each component is essential for executing safe and accurate formwork. Below, these systems are examined based on their respective applications.

Panel-to-Panel Connection Systems: The Core of Formwork Integrity

This category of connections is primarily responsible for joining modular steel formwork panels together on flat surfaces or at corners.

Pin and Wedge

The pin and wedge system is widely regarded as the most fundamental, common, and cost-effective connection used in modular steel formwork systems. This system consists of two components: a pin (male) and a wedge (female).

Operating Mechanism

The connection mechanism is straightforward. The pin is inserted through the punched holes along the edges of two adjacent panels, after which the wedge is driven into the slot of the pin using a hammer to lock it in place. This action firmly secures the two panels together, ensuring a tight and stable joint.

Key Technical Specifications

- Material: Typically manufactured from high-quality structural steel sheets (such as St37) or ductile steel to withstand hammer impacts and applied loads.

- Thickness: Produced in thicknesses of 3, 4, and 5 mm, with 4 mm and 5 mm being the most common and robust options.

- Dimensions and Weight: The pin length generally ranges from 9 to 9.5 cm, while the wedge length is approximately 8.5 cm. The approximate weight of each standard set is between 100 and 110 grams.

- Installation Guidelines: The required number of pin and wedge sets depends on panel dimensions and the judgment of the site engineer; however, as a rule of thumb, between 8 and 16 sets per square meter of formwork are typically used.

- Advantages and Limitations: The primary advantages of this system include rapid installation, very low cost, and ease of training for workers. Conversely, due to the small size of the components, there is a risk of loss on construction sites.

Clamps / Frog Clamp

Clamps function as a more advanced and robust alternative to the pin-and-wedge system and are used in situations where higher precision and greater structural strength are required.

- Applications: This type of clamp is ideal for connections that require precise overlap of formwork panel edges. It is also preferred in projects where a single set of formwork is used repeatedly over numerous cycles—such as tunnel formwork or precast wall systems—due to its superior durability and efficient fastening and release mechanism.

- Technical Specifications: Clamps are manufactured through casting from ductile (nodular) cast iron. This material offers exceptional resistance to both compressive and tensile forces and, unlike ordinary cast iron, is not brittle. This characteristic ensures that the clamp will not fracture under the high pressures exerted by fresh concrete.

Choosing between pin and wedge or clamps is a strategic decision based on project requirements. For standard projects such as foundations and conventional walls, the pin-and-wedge system provides an excellent balance between cost and performance and is therefore the optimal choice. However, for architectural structures, watertight elements, or systems requiring millimeter-level precision and complete joint sealing, investing in cast iron clamps ensures superior final quality and minimizes the risk of execution errors.

Bracing and Support Systems: Resisting Lateral Pressures

In the formwork of double-sided elements such as walls, columns, and large foundations, merely connecting panels together is insufficient. A dedicated system must be implemented to restrain the lateral pressure of concrete, which tends to force the two faces of the formwork apart.

Bolts / Tie Rods

Bolts, or tie rods, are threaded steel bars that pass through both faces of the formwork, clamping them together in a manner similar to a large mechanical fastener.

Types of Bolts

- Fully Threaded Tie Rod: This type of tie rod is threaded along its entire length, allowing precise adjustment of the spacing between the two formwork faces. These rods are typically installed within a PVC sleeve so they can be retrieved and reused after concrete placement.

- Hook Bolt (Soldier Clamp Bolt): This bolt features one bent, hook-shaped end and one threaded end. Its primary application is connecting heavy vertical bracing members (soldiers) to horizontal walers (typically steel pipes).

- Flat Strap Tie (Strip Tie): A simple and rapid solution for restraining low-height formwork such as foundations. This component consists of a steel strip with holes at both ends, which is connected to the formwork using pins and wedges.

Through-Ties / Water Stopper Tie Rods

These components are a specialized type of tie rod designed specifically for watertight concrete structures.

- Specialized Application: Water-stopper through-ties are used in the construction of water tanks, swimming pools, treatment plants, and any structure where leakage is unacceptable. These ties include a central plate or element that blocks the path of water penetration along the tie rod.

- Types: Through-ties are manufactured in three main types: cast iron, steel (spring type), and plastic. Their key distinction is that after concrete placement, the central section remains permanently embedded in the concrete and cannot be reused. External tie rods attached to both ends are removed once the concrete has cured.

Nuts and Washers

These two components complement the tie rod system and play a critical role in force transfer and load distribution.

- Wing Nut: Owing to its two protruding wings, this nut can be quickly tightened or loosened by hand or with a hammer. It is manufactured from ductile (non-brittle) cast iron to withstand the high tensile forces applied by the tie rod without failure.

- Cup / Plate Washer: Also known as a dish washer, this thick and essential steel component is placed between the wing nut and the waler (typically a soldier). Its primary function is to distribute the concentrated load of the nut over a larger surface area, preventing deformation or damage to the supporting member.

- Double Pipe Washer: In cases where two scaffolding pipes are used as vertical walers instead of soldiers, this specialized washer is employed to secure the tie rod.

Reinforcement and Support Systems (Bracing)

To increase the resistance of formwork panels against bending caused by concrete pressure, horizontal and vertical reinforcing members known as bracing are used. The connections in this section are responsible for attaching these bracing members to the formwork panels.

Clamps / Clips

Clamps are the most important connectors between the formwork panels and the bracing members (such as pipes, rectangular hollow sections, or channels).

Types of Clamps:

- Medium Clamp (Pipe-to-Form Clamp / Goat Horn Clamp): This is the most commonly used clamp and is used to connect a scaffolding pipe, serving as a horizontal bracing member, to the formwork panel. The clamp has two prongs that fit into the holes on the panel edge and secure the pipe to the panel using a bolt. Its standard size is approximately 12 cm and it is suitable for pipes with diameters up to 6 cm.

- Long Clamp: This clamp has a similar structure to the medium clamp but with a larger opening and hooks. It is used when larger bracing sections such as rectangular hollow sections (RHS) or channels are used instead of pipes. Its standard length is approximately 18 cm.

- Pipe-to-Pipe Clamp: As the name implies, it is used to connect two pipes that intersect each other (for example, connecting a horizontal brace to a vertical brace).

- Technical Specifications: Clamps are typically manufactured from steel sheet with thicknesses of 4, 5, or 6 mm, and their adjustment bolts have a diameter of 16 mm.

Soldier

Soldiers are heavy and robust steel profiles used as the main vertical bracing members in the formwork of tall walls and structures subjected to very high concrete pressures. Their connection to the formwork system is typically made through a hook bolt (soldier clamp bolt).

Special Connections and Corners

In addition to the primary connections, special components are used for specific applications such as creating corners, work platforms, and leveling the system.

Punched Angles and Corner Pieces

To connect two formwork panels perpendicular to each other and create accurate and rigid internal and external corners in the formwork of columns and walls, modular corner pieces or punched angle brackets are used.

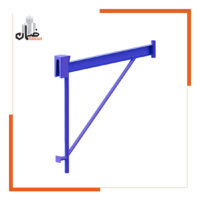

Bracket

This versatile component has a dual function. Firstly, it acts as a base for creating a safe working platform for workers at height. Secondly, it serves as a supporting member for bracing and stabilizing wall formwork.

Prop Jacks and Plumb Jacks

Prop jacks are used to support and adjust the height of formwork for slabs and ceilings. Plumb jacks (or double-arm jacks) are used to vertically align (plumb) and stabilize tall formwork elements such as walls and columns.

Technical Selection Guide: From Material and Thickness to Quality Standards

Selecting the correct formwork connectors goes beyond simply identifying the type of component; it requires a deep understanding of technical specifications, raw materials, and quality standards. An informed buyer can review these details to choose a product that not only meets the immediate project requirements but also offers high durability and reusability, ultimately delivering greater economic value in the long term.

Raw Material Analysis: The Difference in the Core of the Component

The quality of a connector begins with the raw material from which it is manufactured. Two primary materials play a key role in the production of these components:

Steel

For components subjected to tension, bending, and impact—such as pins and wedges, clamps, and washers—the quality of the steel is decisive. Using standard steel sheets such as St37 sourced from reputable suppliers ensures the required strength and ductility of the component. Products made from recycled or low-quality steel may become brittle under impact or permanently deform under pressure.

Ductile Iron

For components that are exposed to high compression and tensile forces and must not exhibit any brittleness—such as wing nuts and frog clamps—the use of ductile iron is essential. The primary difference between ductile iron and ordinary cast iron lies in the graphite structure, which provides enhanced flexibility and impact resistance.

A wing nut made from ordinary cast iron may crack suddenly under the high tension of a tie rod, potentially causing an accident, whereas ductile iron can withstand such loads without failure. This technical characteristic directly translates into improved safety and reliability of the formwork system.

Thickness: The 5 mm Golden Standard

In the connector market, especially for clamps and pins and wedges, various thicknesses such as 4 mm and 5 mm are available. Although the price difference between these options may seem minor, their performance difference is significant.

A thickness of 5 mm has become an industrial standard for heavy-duty and professional projects. This is because the 25% increase in thickness substantially enhances the component’s resistance to bending and deformation.

A 5 mm clamp offers greater durability, can be reused across multiple projects, and provides greater confidence during large-scale concrete pours. Therefore, choosing a 5 mm thickness is a smart investment in the longevity and safety of the equipment.

Quality Indicators: How to Identify a Superior Product

A professional buyer should also be able to assess the visual quality of a product. When purchasing, pay attention to the following points:

- Weld Quality: In components such as clamps, welds should be uniform, continuous, and free of porosity. Poor welding is often the primary weakness of a component.

- Thread Quality: The threads on bolts and nuts should be precise, deep, and free of burrs so they can be tightened smoothly and without binding.

- Consistency in Production: All components within a production batch should be identical in dimensions, weight, and appearance. This indicates the use of accurate and controlled manufacturing processes (such as CNC cutting).

- Final Finishing: High-quality components have smooth edges without sharpness, making them safer to handle.

Ultimately, the most reliable sign of quality is purchasing from a reputable and trusted supplier. A company confident in its products will always be ready to provide detailed technical consultation and transparency regarding raw materials and manufacturing processes.

Practical Guide and Field Calculations

Selecting and purchasing the appropriate formwork connectors is only half the task. Correct usage and estimating the required quantities constitute the second, crucial half of the process, ensuring the success of formwork operations. This section provides a practical table and rule-of-thumb formulas to help contractors plan their projects with greater confidence.

Quick Selection Table for Formwork Connectors by Application

Different construction projects require different combinations of connectors. The table below serves as a quick reference, helping users rapidly identify the key connectors needed based on the type of structure being executed. This table reduces the complexity of choosing from dozens of components and simplifies the decision-making process.

| Application | Primary Panel Connector | Primary Tie System | Bracing System and Its Connectors | Key Notes |

|---|---|---|---|---|

| Standard Concrete Wall | Pin and wedge (for speed and economy) or frog clamp (for precision) | Full-thread tie rod + wing nut + plate washer | Horizontal bracing (pipe) with medium clamp + vertical bracing (soldier) with bent tie rod | Using tie rod sleeves is essential to enable reuse of the rods. |

| Square Column | Pin and wedge + internal and external corners (or punched angle) | Full-thread tie rod or strap tie (for short columns) | Pipe or profile ties with medium/long clamps | Plumb alignment of the column using leveling jacks is essential. |

| Waterproof Tanks and Structures | Frog clamp (for maximum joint sealing) | Water-stopper tie rod (cast iron or metal) + external tie rods | Similar to standard walls, with greater bracing density | Selecting water-stopper tie rods is vital to prevent water leakage. |

| Concrete Slab and Ceiling | (Usually not applicable) | (Usually not applicable) | Formwork props (cross or U-shaped) + adjustable head jacks | Accurate calculation of the number and spacing of props is essential to prevent slab deflection. |

| Strip Foundation | Pin and wedge | Strap tie or full-thread tie rod | Pipe bracing with medium clamps at height | Due to low height, a simpler tie system is usually sufficient. |

Correct and Safe Installation Principles

- Pin and Wedge: Always use controlled hammer strikes. After inserting the wedge, ensure it is securely locked.

- Tie Rods: Tie rods should be tightened alternately and in stages so that pressure is distributed evenly across both sides of the formwork. Avoid overtightening, which can damage the formwork.

- Clamps: After positioning the pipe or profile bracing, tighten the clamp bolt until the bracing is fully secured to the formwork with no movement.

Rule-of-Thumb Calculations for Quantity Estimation

Accurate estimation of connector quantities depends on execution drawings and the project engineer’s judgment. However, the following rules of thumb can be used for preliminary estimates:

- Pin and Wedge: On average, 8 to 16 pairs of pins and wedges are required per square meter (m²) of formwork surface. The higher number applies to smaller panels and more complex designs, while the lower number applies to larger panels and flat surfaces.

- Tie Rods (for two-sided walls): On average, one tie rod of suitable length is required for every two square meters (2 m²) of wall surface. This corresponds to an approximate spacing of 1 meter between tie rods in both horizontal and vertical directions.

These calculations help project managers gain better visibility of the required volume of connectors during the estimation and procurement phase. For precise calculations, consultation with technical experts is always recommended.

Why Source Formwork Connectors from ZamanCo?

In the competitive construction equipment market, choosing a reputable supplier is a strategic decision that directly affects the quality, safety, and economy of a project. ZamanCo, with a deep understanding of the building industry’s needs and based on professional principles, positions itself not merely as a seller but as a reliable partner for infrastructure projects.

Uncompromising Commitment to Quality

The foundation of ZamanCo’s operations is built on an unwavering commitment to quality. We believe that the durability and safety of your structures depend on the quality of every single component used, including the smallest connectors. Therefore:

- Premium Raw Materials: We use the best available raw materials, including standard steel sheets and ductile cast iron, to manufacture our products. This selection ensures high strength and long service life.

- Precise Manufacturing Processes: By utilizing modern technologies and multi-stage quality control, we produce consistent, accurate products that meet industrial standards and perform flawlessly on site.

Comprehensive Product Range: Meeting All Your Needs

A construction project requires a wide spectrum of connectors. ZamanCo eliminates the need to source from multiple suppliers by offering a complete product portfolio, simplifying the procurement process for you. From common pins and wedges and clamps to heavy-duty soldiers, specialized brackets, and various water-stopper tie rods, everything required for a complete formwork system is available at ZamanCo.

Expert Consultation: Beyond Sales

Our team of technical experts, composed of experienced professionals in the field of formwork, is ready to provide you with free consultation. We assist you in:

- Correct Selection: Choosing the most suitable and economical connectors based on the type of structure and project complexity.

- Accurate Calculation: Precisely estimating the required quantities of each component to prevent over-purchasing or equipment shortages during execution.

This consultative approach transforms ZamanCo from a mere supplier into a technical partner and supporter of your project.

Transparent and Competitive Pricing

While maintaining the highest quality standards, we always strive to offer products at fair and competitive prices. Understanding the fluctuations in the steel market, our pricing is transparent and updated regularly so that you can confidently plan your project budget. Our goal is to deliver the best “value”: a combination of superior quality, long-lasting durability, and reasonable cost that reduces your expenses over the long term.

To build strong, safe, and precise structures, invest in the quality of your connectors.

Contact ZamanCo’s sales experts today to view the complete product list and request current pricing. Take advantage of our free specialized consultation for your project. Let ZamanCo be your partner in building a stable future.

Frequently Asked Questions (FAQ)

This section answers some of the common questions customers have regarding the selection and use of formwork connectors.

1. What is the main difference between light and heavy pins and wedges?

The primary difference is the thickness of the steel sheet used in their production. Heavy pins and wedges are typically made from 4 mm or 5 mm thick steel, whereas the light type may use a thinner sheet (such as 3 mm). The heavy type offers significantly greater strength and durability and is recommended for professional projects and frequent use.

2. Which type of tie rod should be used for pool walls or water tanks?

For any structure requiring complete waterproofing, the use of a water-stopper tie rod is mandatory. This component includes a central plate or washer that remains embedded in the concrete and blocks the potential path of water. Standard tie rods that are removed after concreting are not suitable for this application, as the remaining void can become a leakage pathway.

3. What is the difference between a medium clamp and a long clamp in terms of bracing?

- Medium Clamp (Pipe-to-Formwork / “Goat Horn” Clamp): Specifically designed to connect scaffolding pipes used as horizontal bracing to the formwork panel.

- Long Clamp: Features a larger opening and is used for connecting larger-section bracing elements such as box profiles or channels to the formwork.

4. Are connector prices fixed?

No. The prices of most formwork connectors, especially those made from steel (such as pins and wedges, clamps, and tie rods), are heavily dependent on the current market price of steel sheets. Due to market volatility, prices are not fixed, and it is recommended to request the latest pricing from the supplier before purchasing.

5. How can I calculate the number of pins and wedges required for my project?

A common rule of thumb is to assume approximately 16 pairs of pins and wedges per square meter of formwork surface. This number may vary slightly depending on panel dimensions and hole spacing. For precise calculation, it is advisable to consult technical experts.

6. Is using frog clamps instead of pins and wedges always better?

Not necessarily; it depends on the application.

Frog clamps are superior for applications requiring extremely high precision, perfect panel alignment, and complete joint sealing (such as exposed concrete or water tanks).

Pins and wedges are a very suitable and efficient choice for general projects where execution speed and lower cost are prioritized.