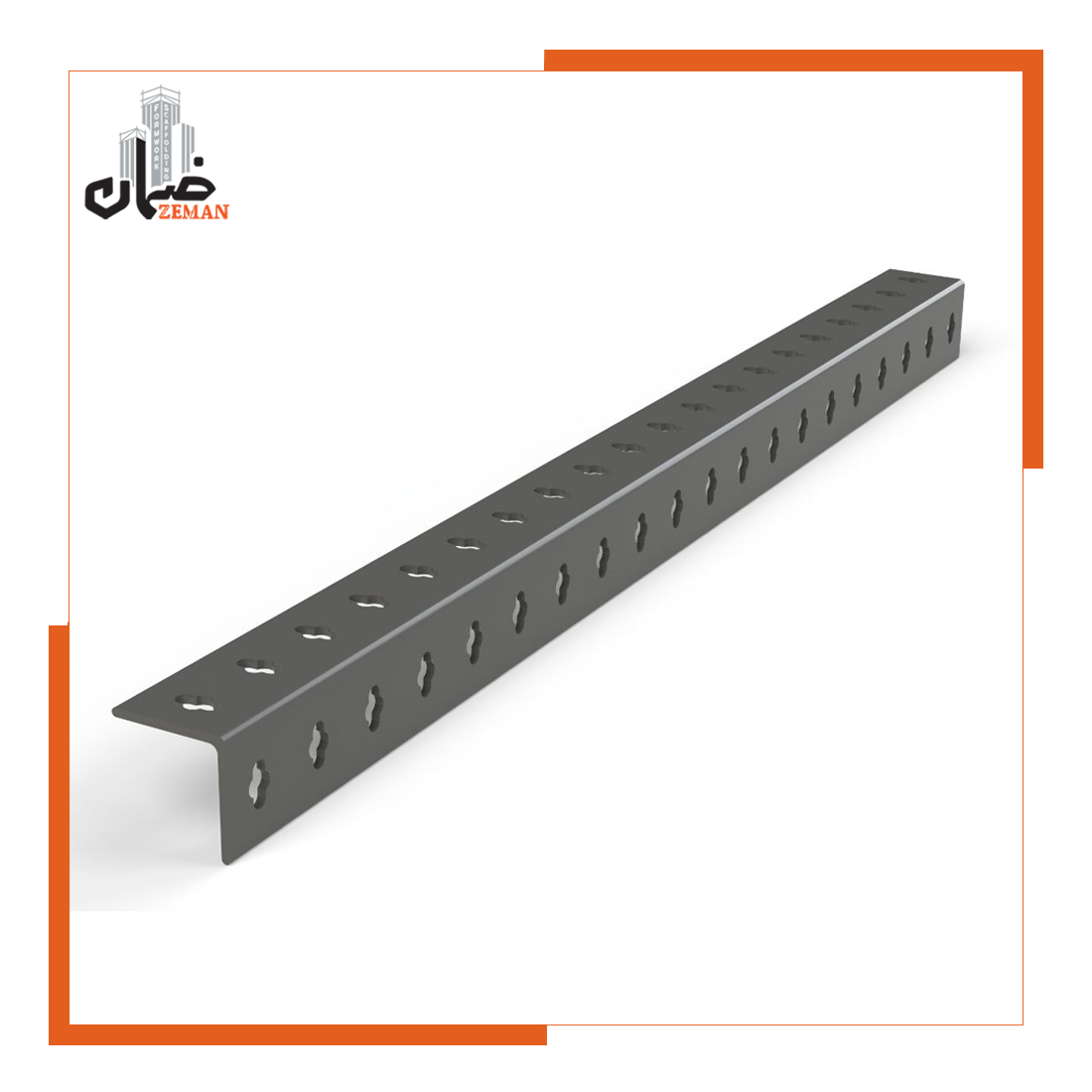

Metal Formwork Zero Corner Angle

Metal Formwork Zero Corner Angle is one of the most essential components in concrete formwork systems, used for connecting and reinforcing formwork panels at corners and edges.

- Definition of Zero Corner Angle: A zero corner angle is a steel angle specifically used at the junction of two formwork panels (typically at internal corners). It ensures panel stability, prevents concrete leakage, and maintains proper alignment of the formwork.

- Application of Zero Corner Angle: Used to connect corner joints of metal formwork in concrete casting applications (such as columns, walls, and foundations). It prevents panel separation or movement under fresh concrete pressure, maintains precise 90‑degree angles at internal corners, and contributes to effective sealing of the formwork system.

- Difference from Standard Angle Sections: The zero corner angle is purpose‑designed for formwork systems and typically features holes or pin slots for fast and secure installation. Standard structural angles are intended for steel frameworks and have no direct application in concrete formwork.

Metal Formwork Zero Corner Angle

In the world of civil engineering and modern construction projects, precision in execution details is what distinguishes an ordinary structure from an engineering masterpiece. One of the most challenging aspects of these details is achieving perfectly sharp, accurate, and true 90-degree corners in concrete elements. This is where a highly specialized yet remarkably efficient component known as the Zero Corner Angle for metal formwork comes into play. This component, also referred to in the industry as a punched angle or zero-radius corner, provides an intelligent solution to this technical challenge.

The use of multiple names for this product can sometimes create confusion among construction industry professionals. This guide aims to serve as a complete and comprehensive reference by thoroughly examining this key component in formwork systems. In this article, Zaman Company, as a leading manufacturer of formwork equipment, introduces the definition, operating mechanism, strategic applications, technical and economic advantages, as well as proper selection and correct usage of the zero corner angle.

Our objective is to provide knowledge that enables engineers, contractors, and project executors to make confident decisions in pursuit of the highest possible quality in their concrete structures. This product is considered an integral part of modern concrete formwork systems.

What Is a Zero Corner Angle and How Does It Differ from Other Corner Connections?

To fully appreciate the true value of the zero corner angle, it is first necessary to understand its nature, functional mechanism, and how it differs from other common connections such as external corners. These differences transform the zero corner angle into a problem-solving tool for specific construction scenarios.

Precise Definition and Operating Mechanism

The zero corner angle, also known as a punched angle, is a metal component manufactured from a steel sheet of specific thickness, bent longitudinally and perforated with accurately spaced holes along its length. The primary function of this component is to connect two perpendicular metal formwork panels at the external corners of a concrete element.

The most significant technical characteristic and key differentiator of the zero corner angle is that it has no contact with the concrete surface. Unlike external corners, which cover part of the concrete surface, the zero corner angle connects and restrains the two formwork panels from the outside at an exact 90-degree angle only. This operational mechanism offers remarkable advantages, as it prevents the formation of any lines, seams, or surface imperfections on the finished concrete. The result is a perfectly smooth, sharp, and flawless corner, which is particularly critical in architectural and façade projects where surface quality is paramount.

Technical Comparison: Zero Corner Angle vs. External Corner

In many references, the zero corner angle is introduced as a substitute for the external corner; however, this represents only part of the reality. Selecting between these two components is a strategic decision based on specific project requirements. The zero corner angle is employed in situations where the external corner is either unsuitable or fails to deliver the desired result. These scenarios include:

- Spatial Limitations: In certain areas of a project, external obstacles or proximity to other structural elements may not allow sufficient space for installing bulkier external corners. The compact design of the zero corner angle effectively resolves this issue.

- Architectural Precision: When architectural drawings require zero-radius (perfectly sharp) corners, standard external corners may be unable to achieve the necessary accuracy due to their structural configuration. The zero corner angle is ideal for creating clean and precise architectural lines.

- Specialized and Complex Applications: One of the most common and critical applications of the zero corner angle is connecting soffit beam formwork (suspended beam formwork) to slab or deck formwork. In such complex connections, the use of external corners is virtually impossible, making the zero corner angle the only effective solution for a strong and accurate joint.

- Logistics and Storage Optimization: For contractors, storing zero corner angles in various lengths can be more logistically efficient than stocking multiple rigid and bulky external corners.

Therefore, the zero corner angle is not merely an alternative component but a specialized solution designed to address challenges that standard corner connectors cannot effectively resolve.

Key Applications of Punched Angle in Formwork Projects

The versatility of the zero corner angle enables it to play a critical role in various stages of the concrete formwork process, from foundations to architectural façades. Some of its most important applications are outlined below.

Concrete Beam Formwork

As previously mentioned, the most vital application of the zero corner angle is in connecting soffit beam formwork to slab formwork. This precise connection ensures the integrity of the beam–slab intersection and prevents the formation of steps or misalignments that could adversely affect both structural performance and visual appearance.

Construction of Columns and Shear Walls

In vertical load-bearing elements such as columns and shear walls, squareness and dimensional accuracy are of utmost importance. By guaranteeing a perfect 90-degree angle at corners, the zero corner angle helps produce columns and walls with precise square or rectangular geometry. This accuracy not only supports structural performance but also facilitates subsequent stages such as drywall installation and other finishing works.

Foundation Formwork

Precision in foundation execution establishes accuracy throughout the entire structure. The zero corner angle is used to create accurate corners for foundation walls, concrete strips, and pile caps, ensuring that the structural base is constructed strictly according to execution drawings.

Architectural Structures and Exposed Concrete Façades

In projects where concrete serves as the final exposed surface (architectural concrete), surface quality and sharp architectural lines are a priority. The zero corner angle is an ideal tool for achieving crisp edges and straight lines in architectural elements, façade walls, and decorative concrete structures.

Strategic Advantages: Why Is the Zero Corner Angle a Smart Investment?

The use of a zero corner angle extends beyond a mere technical choice; it represents a strategic decision that delivers tangible benefits in quality, cost efficiency, and execution time.

Engineering Precision and Superior Surface Quality

The primary advantage of the zero corner angle lies in producing sharp, precise edges. Additionally, since this component does not come into contact with concrete, it results in a smooth and defect-free surface. This significantly reduces costs associated with surface repair, patching, and finishing after formwork removal and produces a final output that meets the most stringent architectural standards.

Enhanced Strength and Stability of the Formwork System

The zero corner angle acts as a reinforcement element within the formwork assembly, enabling it to withstand the high hydrostatic pressure of fresh concrete. The solid joint created by this component prevents joint separation and leakage of cement slurry. Preventing slurry leakage not only improves site cleanliness but also offers an important structural advantage: cement slurry is rich in water and cement, and its loss alters the water–cement ratio at the concrete surface, potentially reducing surface strength and durability.

Improved Installation Speed and Workforce Productivity

The simple design of the zero corner angle allows for rapid and straightforward installation. Furthermore, after concrete curing, this component facilitates easier formwork dismantling. Faster formwork cycles (installation and removal) directly contribute to accelerated project schedules and significant savings in labor costs.

Flexibility and Reusability

Due to its straightforward design, the zero corner angle provides high flexibility in connecting formwork panels. Manufactured from durable steel, it offers excellent reusability. This reduces the cost per use and makes it a cost-effective long-term investment across single or multiple projects. To form a robust formwork system, the zero corner angle is used alongside other connectors such as pin and wedge and soldier.

Technical Specifications and Complete Weight Table of Zaman Zero Corner Angle

To correctly select and order the appropriate zero corner angle, access to precise technical data is essential. Zero corner angles are typically manufactured in lengths of 0.5, 1, 1.5, and 2 meters, with flange widths of 5 and 6 centimeters and steel sheet thicknesses of 3 and 4 millimeters. These components are compatible with both bent-edge and flat-edge formwork systems. Zaman Company provides the comprehensive table below to assist you in selecting the exact product required for your project.

Comprehensive Technical Specifications and Weight Table of Zaman Zero Corner Angle

| Product Code | Length (m) | Flange Width (cm) | Sheet Thickness (mm) | Compatible Formwork Type | Approx. Weight (kg) | Recommended Application |

|---|---|---|---|---|---|---|

| ZC-0553 | 0.5 | 5 | 3 | Bent-edge / Flat-edge | 0.8–1.0 | Short connections, stair formwork |

| ZC-1053 | 1.0 | 5 | 3 | Bent-edge / Flat-edge | 1.6–2.0 | Standard wall and column formwork |

| ZC-1553 | 1.5 | 5 | 3 | Bent-edge / Flat-edge | 2.4–3.5 | Tall wall and column formwork |

| ZC-1063 | 1.0 | 6 | 3 | Flat-edge | ≈3.2 | Enhanced coverage and strength for 6 cm formwork panels |

| ZC-0554 | 0.5 | 5 | 4 | Bent-edge / Flat-edge | 1.0–1.4 | High concrete pressure in short spans |

| ZC-1054 | 1.0 | 5 | 4 | Bent-edge / Flat-edge | 2.0–2.8 | Heavy-duty projects, high-speed concrete pouring |

| ZC-1554 | 1.5 | 5 | 4 | Bent-edge / Flat-edge | 3.0–4.3 | Tall walls with very high concrete pressure |

| ZC-1064 | 1.0 | 6 | 4 | Flat-edge | ≈4.0 | Maximum strength for 6 cm flat-edge formwork systems |

This table goes beyond a simple listing and functions as a decision-making tool. Through the “Recommended Application” column, users can quickly identify the most suitable model for their specific project requirements—for example, selecting 4 mm thickness angles for heavy-duty projects with high concrete pouring rates.

Step-by-Step Guide to Proper Installation and Use of the Zero Corner Angle

Correct installation of the zero corner angle is essential to fully benefit from its advantages. The following steps provide a practical on-site installation guide:

- Select the Appropriate Angle: Based on the technical specifications table, choose the correct length and thickness according to formwork height and anticipated concrete pressure. For taller walls and faster pouring rates, thicker angles (4 mm) are recommended.

- Preparation and Positioning: Ensure that the formwork edge surfaces are clean and free from any debris. Position the zero corner angle precisely at the external joint of two perpendicular panels.

- Connection and Fixing: Align the holes of the zero corner angle with the slots on the formwork edges. Secure the connection using pin and wedge. Insert the pin through the aligned holes and drive the wedge firmly with a hammer to create a rigid, play-free connection.

- Final Inspection: Prior to concrete pouring, inspect all connections to ensure wedges are fully secured and that the corner formed is perfectly square and plumb.

Important Note: Do not confuse the zero corner angle used in formwork with wall posts or permanent structural angle bracing. The zero corner angle is a temporary component used exclusively in formwork systems and is removed after concreting. In contrast, wall posts or permanent angle bracing are structural elements installed permanently to restrain non-structural walls against lateral forces such as earthquakes and are fixed to the main structure by welding or bolting. These applications are entirely different and must not be mistaken for one another.

Zaman Zero Corner Angle: Superior Quality for Long-Lasting Projects

Leveraging extensive technical expertise and long-standing industry experience, Zaman Company manufactures zero corner angles that guarantee quality and durability for your projects.

- High-Quality Raw Materials: We use premium steel sheets, including Mobarakeh Steel, to ensure maximum durability and reusability.

- Precision Manufacturing: Our advanced production processes ensure dimensional accuracy, precisely punched holes, and a perfect 90-degree angle in every product.

- Full Compatibility: Zaman zero corner angles are fully compatible with the complete modular metal formwork system of the company as well as other standard formwork systems available on the market, ensuring flawless connections and optimal performance.

For expert consultation on selecting the most suitable formwork connectors for your project and to receive current pricing, please contact our specialists at Zaman Company.

Frequently Asked Questions About Zero Corner Angle

This section addresses the most common questions regarding metal formwork zero corner angles to make selection and usage easier for you.

What is the main difference between a zero corner angle and an external corner?

The main difference lies in contact with concrete. External corners cover part of the concrete surface, whereas the zero corner angle has no contact with concrete, resulting in a sharper and smoother corner. Additionally, zero corner angles are used in specific conditions such as limited space or complex connections (e.g., beam-to-slab joints).

How should I choose the appropriate thickness (3 mm or 4 mm)?

Thickness selection depends on concrete pressure. For standard-height formwork and normal pouring speeds, a 3 mm thickness is sufficient. For tall walls, high-speed pouring, or heavy-duty projects with elevated pressure, a 4 mm thickness is recommended for greater resistance.

Is the zero corner angle compatible with all metal formwork systems?

Yes, the zero corner angle is designed for use with standard modular formwork systems that feature consistent hole/slot patterns. It is compatible with both bent-edge and flat-edge formwork types.

What factors affect the price of zero corner angle?

The price of the zero corner angle is primarily influenced by global steel prices as the main raw material, as well as product dimensions including length, flange width, and thickness.

How can I place an order with Zaman Company?

The ordering process is straightforward. Simply contact our sales experts via phone or email, receive professional consultation, obtain your official quotation, and finalize your order upon confirmation.

Conclusion: Zero Corner Angle—A Smart Investment in Precision and Structural Quality

In conclusion, this comprehensive review demonstrates that the metal formwork zero corner angle goes far beyond a simple connector; it is a critical engineering tool for achieving architectural precision, ensuring structural quality, and optimizing execution processes in concrete projects. Its key advantages—ranging from flawless corner formation and enhanced formwork stability to time and cost savings—make it a smart investment for any contractor or developer who values quality and durability.

At Zaman Company, we are committed to providing solutions that help you construct precise, robust, and long-lasting structures. The zero corner angle is just one of the many formwork connection solutions we offer to elevate the standard of your projects.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.