Hammer Scaffolding

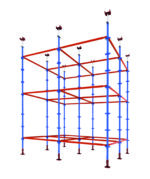

Hammer scaffolding, also known as Star Scaffolding or Ringlock Scaffolding, is one of the most modern and widely used modular scaffolding systems in the world, marking a major revolution in the construction industry. Its popularity stems largely from its exceptional simplicity and speed in assembly and disassembly, which are carried out using only a hammer, eliminating the need for any wrenches or complex tools.

In today’s highly competitive construction environment, time is literally money. Projects completed faster and with higher safety standards naturally yield greater profitability. Hammer scaffolding—also referred to as star scaffolding or ringlock—directly addresses this demand. By eliminating bolts, nuts and time‑consuming fittings, this innovative system allows you to erect even the most complex scaffold structures at remarkable speed using nothing more than a hammer. From the façade of a residential tower to the core of an industrial refinery, hammer scaffolding is the smart, efficient and safe access solution you can rely on.

Hammer Scaffolding

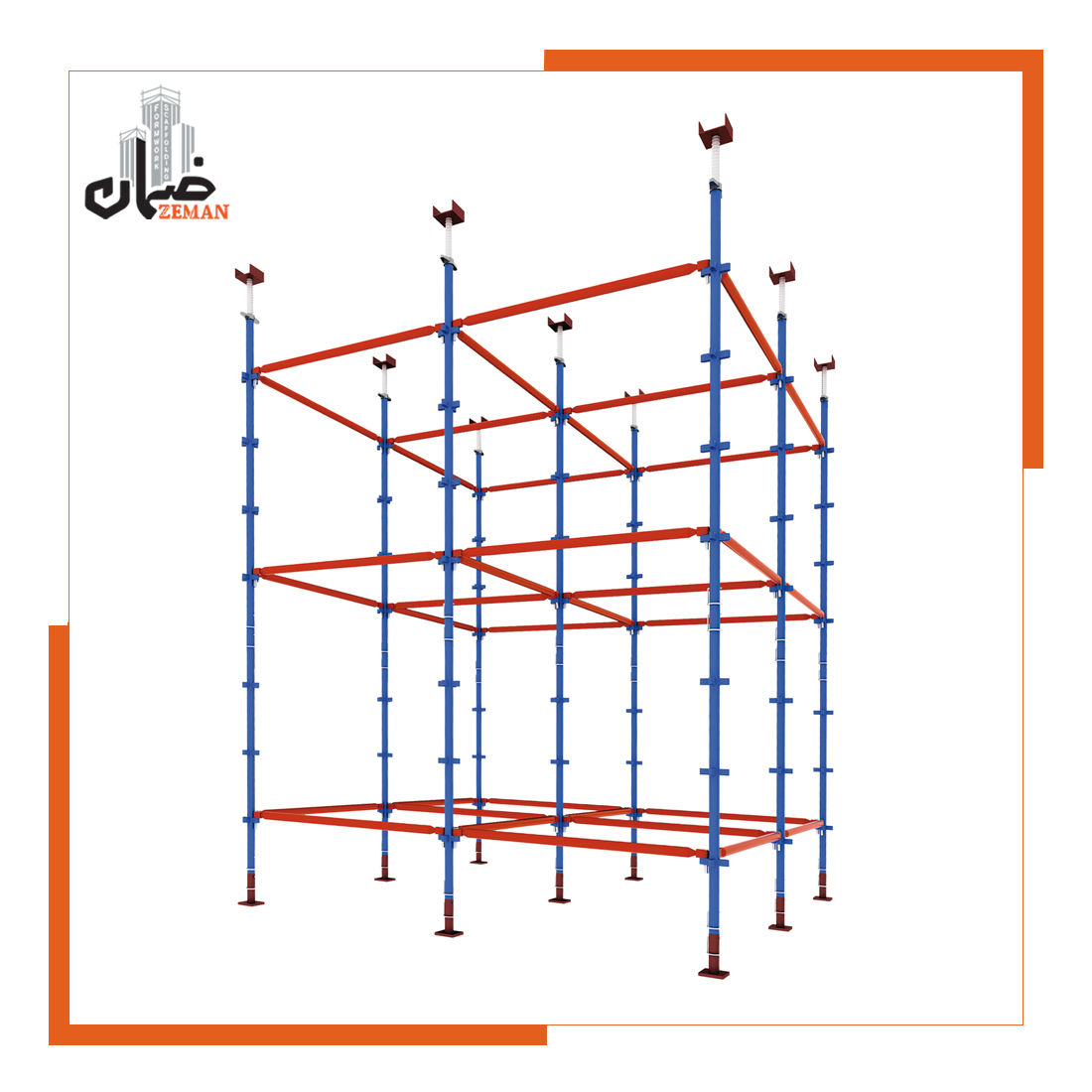

Hammer Scaffolding System

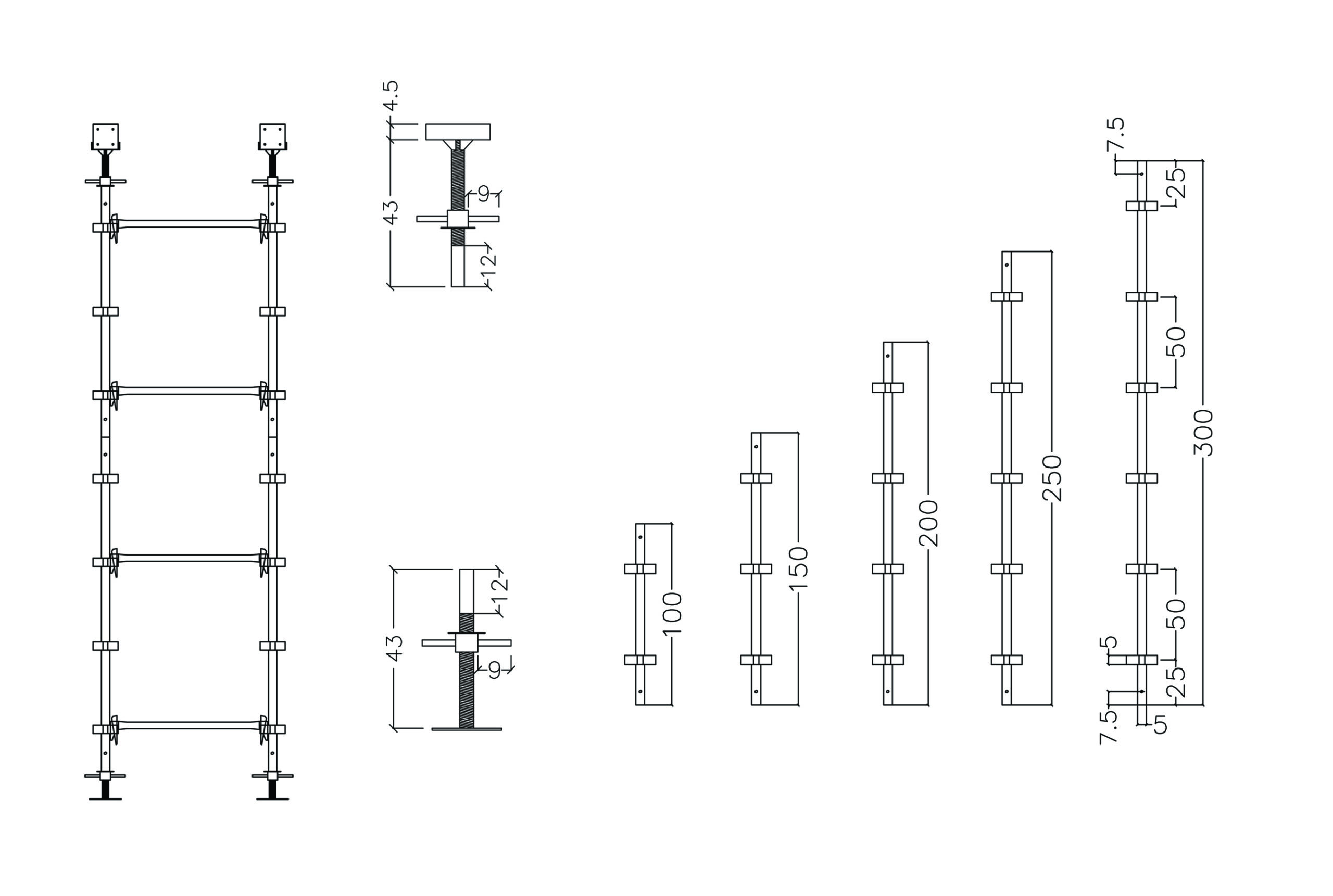

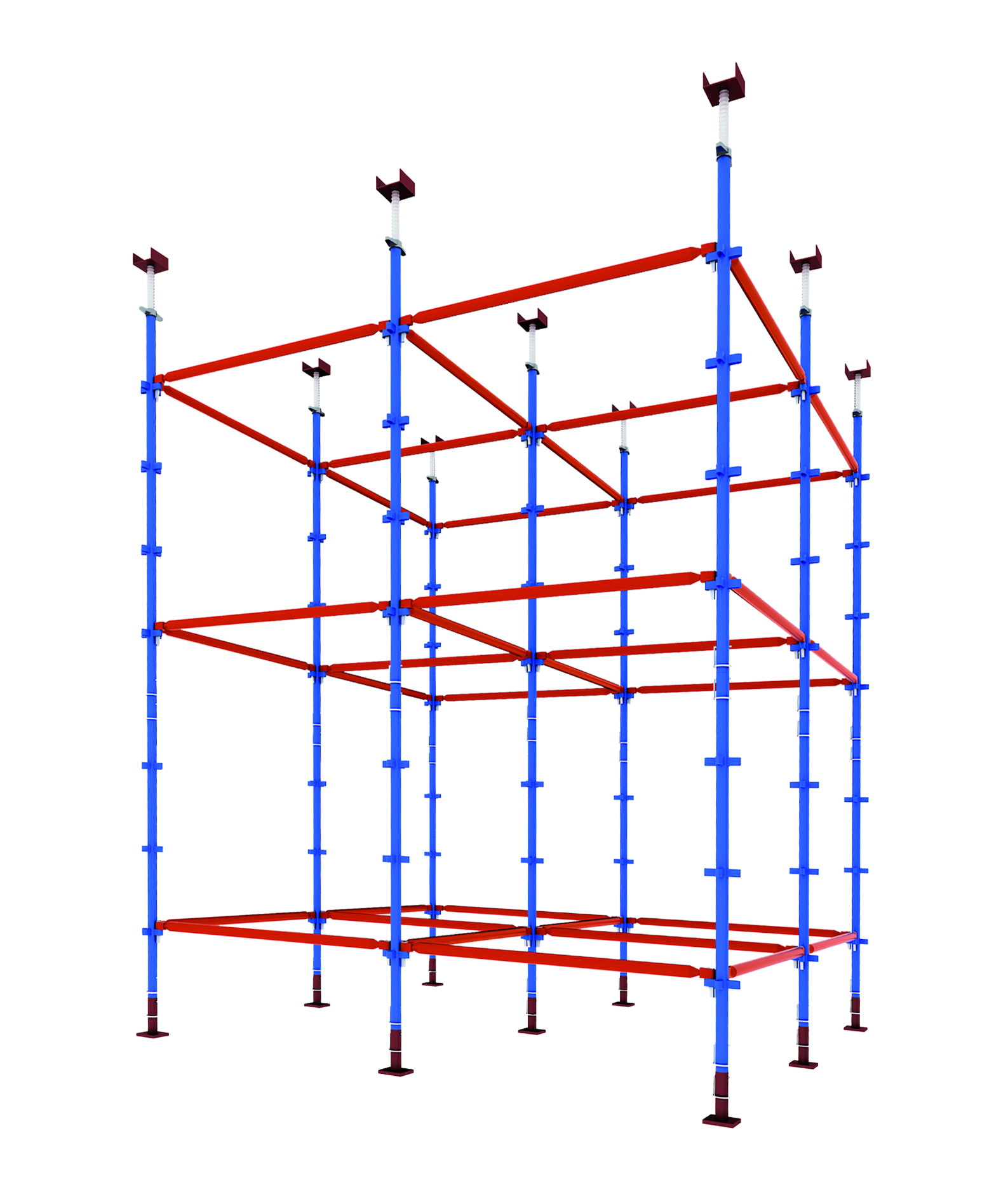

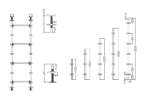

This type of modular scaffolding consists of vertical standards and horizontal ledgers in various sizes. The vertical members are typically produced in lengths of 3 m, 2.5 m, 2 m, 1.5 m and 1 m. Adjustable jack heads at the top and adjustable base jacks at the bottom enable full height and level alignment on uneven surfaces. Installing the horizontal ledgers onto the vertical standards is easily accomplished with a hammer blow, and connecting the standards to each other is achieved using internal spigots and scaffold pins. In industrial and petrochemical projects, depending on structural conditions, either cup‑lock scaffolding or hammer scaffolding is commonly used.

What Is Hammer Scaffolding and Why Is It a Smart Choice?

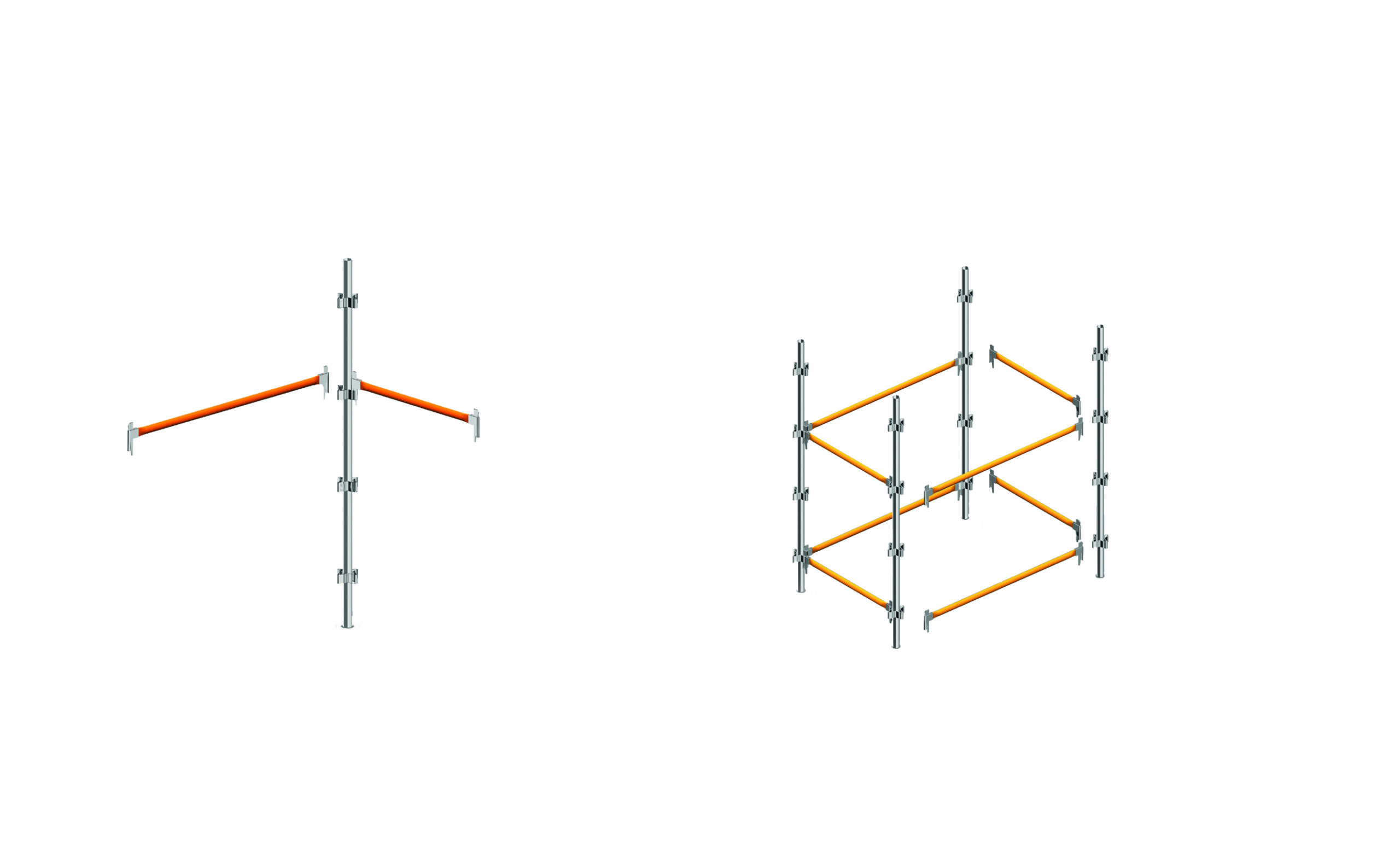

Hammer scaffolding is an advanced modular system whose strength lies in its unique locking mechanism:

• Rosette (Star Fitting): A steel disk with 8 connection points welded at fixed intervals along the vertical standards.

• Locking Pin: Located at the ends of the horizontal and diagonal braces.

To connect the components, the pin is placed into the corresponding slot on the rosette and locked with a single hammer blow. This positive, play‑free connection delivers exceptional rigidity and safety. The simplicity of this design reduces dependency on highly skilled labor and dramatically accelerates project execution.

Anatomy of the Main Components of Hammer Scaffolding

The efficiency of this system comes from its intelligently engineered components:

Vertical Standards:

The main load‑bearing elements, equipped with welded rosettes at regular intervals (typically every 50 cm), each containing eight connection openings.

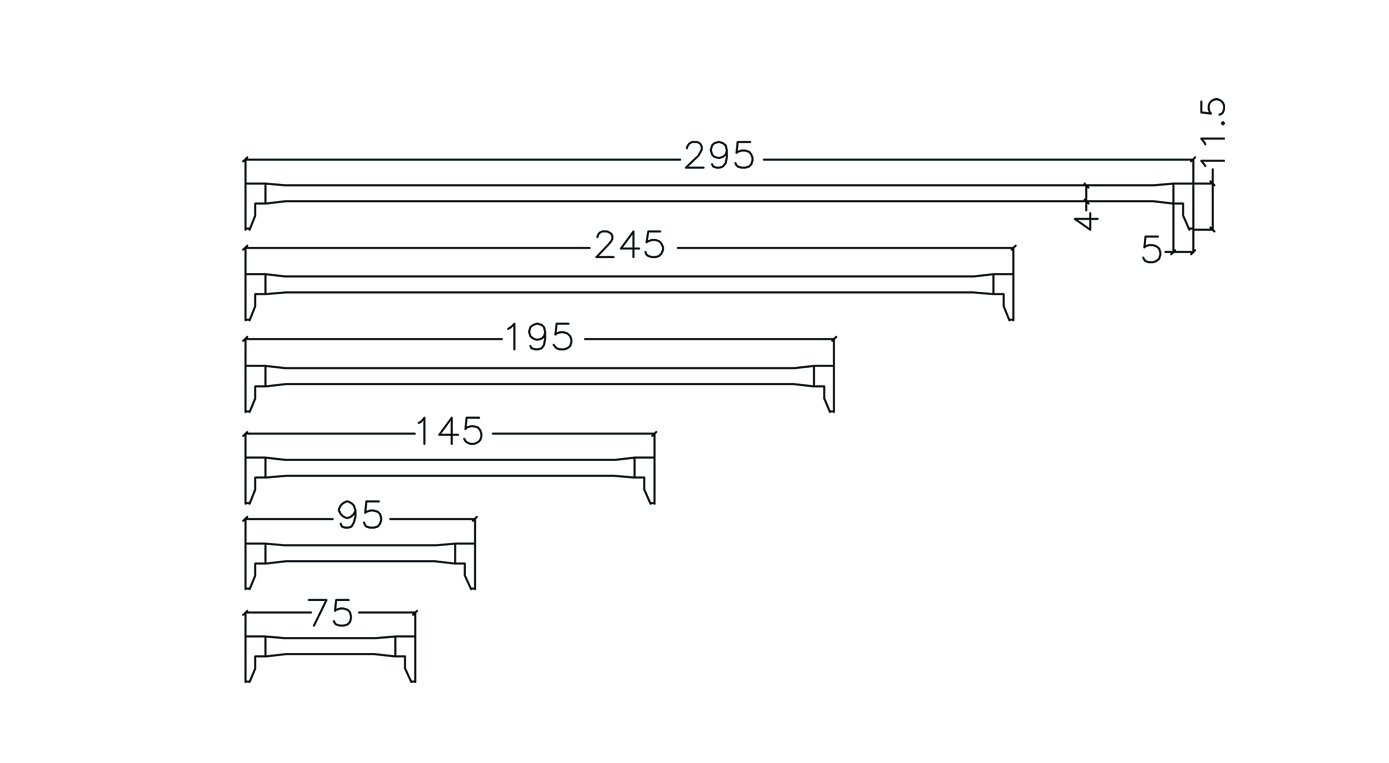

Horizontal Ledgers:

Fitted with locking pins at each end, these members connect the standards, support working platforms, and lock securely into the rosettes with a hammer blow.

Diagonal Braces:

Installed in a cross‑pattern to provide increased rigidity and stability against lateral forces such as wind.

Adjustable Base Jack:

Used under the main standards to achieve precise leveling on uneven or sloped surfaces.

Scaffold Platform:

Perforated, anti‑slip metal planks that rest on the horizontal ledgers to create a safe working surface.

Applications: From Building Facades to Refineries

The versatility of hammer scaffolding makes it suitable for a wide range of projects:

• Façade Scaffolding: The fastest and most efficient solution for building exteriors.

• Industrial & Petrochemical Plants: Ideal for providing complex access around tanks, pipelines and equipment.

• Event Staging: For rapid installation of stages, lighting towers, and exhibition structures.

• Shoring (Load‑Bearing Scaffolding): Can be used as a strong support system in formwork and heavy shoring applications.

Frequently Asked Questions (FAQ)

What is the main difference between hammer scaffolding and cuplock scaffolding?

Both are advanced modular systems, but their locking mechanisms differ. Hammer scaffolding offers faster assembly due to its simplified hammer‑lock connection, while cuplock provides exceptional stability in high‑vibration environments such as marine structures.

Does star scaffolding really require no specialized labor?

Assembly is significantly easier than traditional tube-and-coupler systems and does not require a master scaffolder. However, any scaffolding system—especially at height—must be installed under the supervision of trained personnel and with full adherence to safety standards.

Why is Zeman Hammer Scaffolding a smart investment?

Because quality directly impacts safety and long‑term durability.

• Manufactured to Standard: Produced using heavy‑duty pipes, true wall thickness, and CO₂ welding for maximum strength.

• Factory‑Direct Pricing: Purchasing directly eliminates intermediaries and ensures the best market price.

• Technical Support: Our team assists you in selecting and calculating the exact quantity of components needed for your project.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.