Formwork Soldier

Key Features of Concrete Formwork Soldiers: A reinforcing structural member designed to stabilize formwork systems and transfer loads from wall and column formwork to props or bracing elements.

- Manufactured from heavy-duty steel profiles such as box sections, U-channels, or I-sections

- Equipped with purpose-designed perforations for fast connection to props, bolts, and other formwork accessories

- Controls and distributes the pressure of fresh concrete in vertical formwork systems

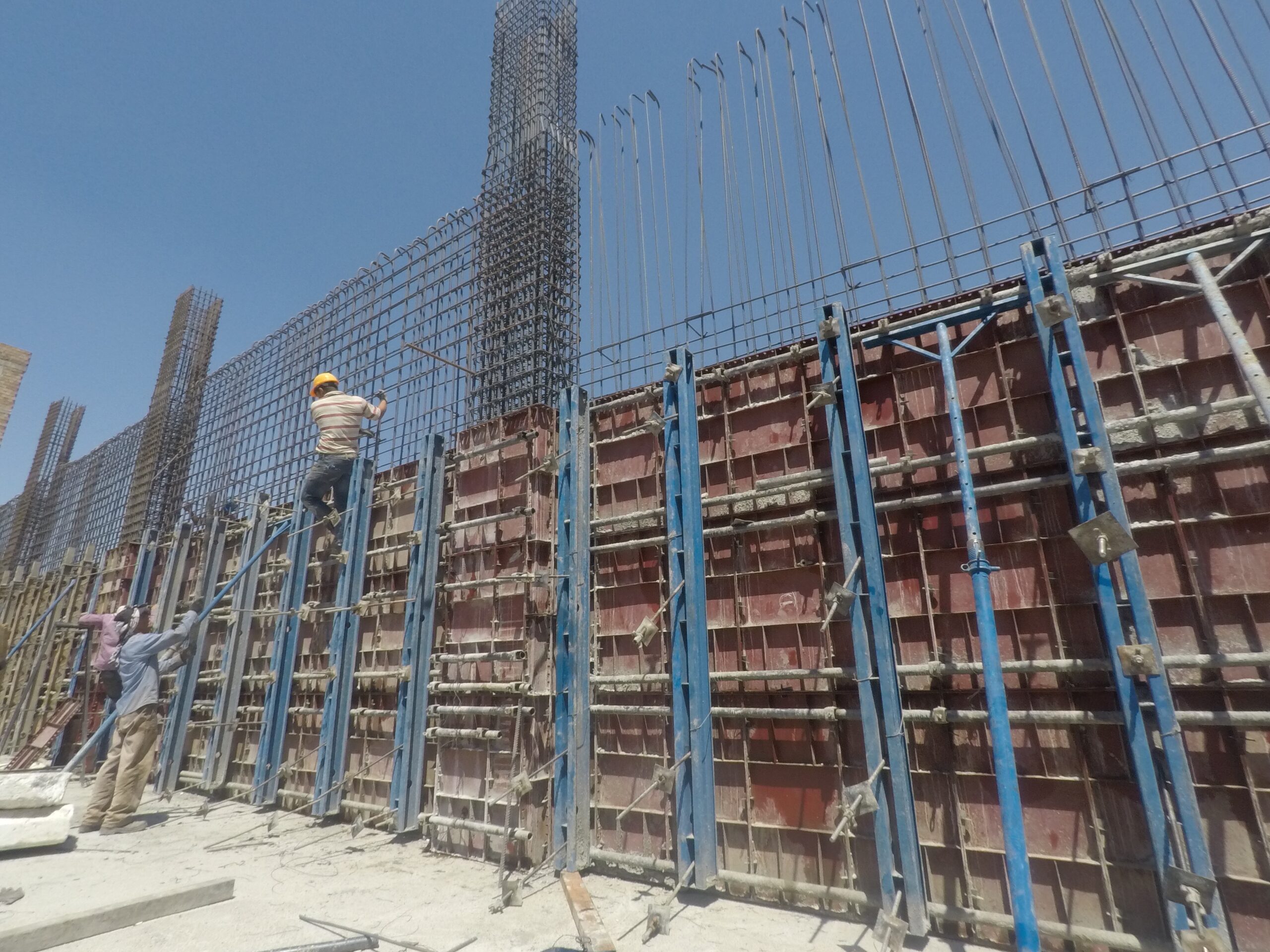

- Suitable for large-scale projects such as tunnels, bridges, shear walls, and special structural applications

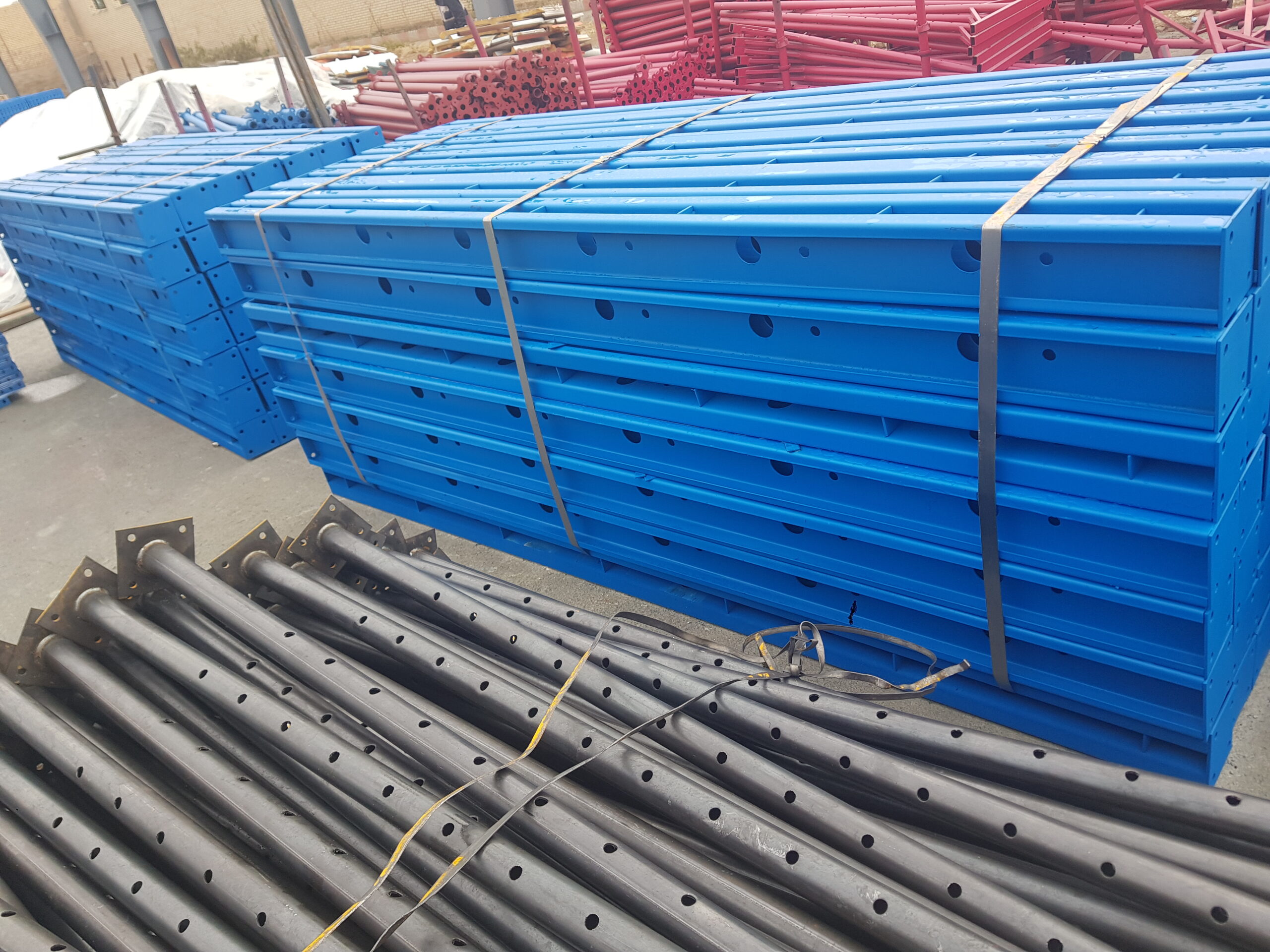

- Fast installation, multiple reuse cycles, and high resistance to concrete pressure

- Improves the dimensional accuracy of finished concrete structures such as walls and columns

Formwork Soldier

Formwork Soldier in concrete forming systems is one of the key components used to strengthen, stabilize, and transfer loads from vertical formwork elements such as walls and columns to props, braces, or shoring systems. Soldiers are typically installed vertically or horizontally behind the formwork panels to control and evenly distribute the pressure exerted by fresh concrete.

Soldier Characteristics

- Material: Commonly manufactured from heavy-duty steel box sections or U- / I-shaped channels with high thickness.

- Length: Typically designed in lengths ranging from 1 to 3 meters (custom lengths available).

- Design: Usually provided with perforations to allow connection to props, bolts, or formwork accessories.

Applications of Formwork Soldiers

- Enhancing formwork strength and preventing deformation or opening due to concrete pressure

- Connecting to push-pull props or steel bracing systems

- Distributing concrete pressure in wall, column, and shear wall formwork

- Use in tunnel formwork, bridges, and large-scale infrastructure projects

Advantages: reusable for multiple projects, high resistance to fresh concrete pressure, fast installation and execution, and improved dimensional accuracy of finished concrete walls or columns.

Introduction: The Hidden Force Behind Mega Concrete Structures

At the heart of every massive concrete structure—ranging from soaring skyscrapers to expansive bridges and robust dams—lies a powerful and seemingly uncontrollable force: the hydrostatic pressure of fresh concrete. This pressure, comparable to a restrained flood force, represents a core engineering challenge that ultimately determines the success or failure of any concreting operation. When faced with this immense force, the formwork system becomes the frontline defense of the structure, and within this system, a crucial component plays a vital yet often unseen role—the backbone of the entire setup: the Formwork Soldier.

A soldier is far more than a simple steel member; it is a high-performance engineered component designed to restrain applied loads and ensure overall stability and dimensional accuracy. Without the high strength and bending resistance of soldiers, formwork panels would deform, distort, or even suffer catastrophic failure under the weight of fresh concrete.

This guide serves as one of the most comprehensive technical and commercial references on formwork soldiers for civil engineers, contractors, project managers, and construction professionals. In the following sections, we examine this critical component in detail—from material science and structural analysis to market evaluation, return on investment (ROI), advanced execution techniques, and safety protocols. The objective is to provide deep, practical knowledge that enables informed selection, procurement, and execution of soldier systems to achieve the highest levels of quality, speed, and safety in construction projects.

Dissecting the Formwork Soldier: Definition and Fundamental Principles

To fully understand the role and importance of the formwork soldier, it is essential to define it precisely from an engineering standpoint, distinguish it from similar terms, and understand the physical principles governing its behavior. This section lays the technical foundation for all subsequent discussions.

What Is a Formwork Soldier? A Precise Engineering Definition

In civil engineering and formwork systems, a soldier is a high-strength vertical load-bearing member with a significant moment of inertia, acting as the main vertical support in wall, column, and other concrete formwork systems. Its primary function is to resist bending forces induced by the lateral pressure of fresh concrete and transfer these loads—via horizontal walers—to tie systems or shoring elements. In essence, the soldier prevents deformation, opening, or failure of formwork panels and maintains the integrity of the entire system during concrete placement.

Clarifying the Confusion: Formwork Soldier vs. Soldier Pile

One of the most common misconceptions in the construction industry is confusing the term “formwork soldier” with “soldier pile.” Understanding the distinction between these two entirely different applications is essential and reflects a high level of technical awareness.

- Soldier Pile (Berlin Wall System): A geotechnical solution used to stabilize excavations and retain soil in deep digging operations. It consists of steel or concrete piles installed at intervals, with the space between them filled with timber lagging, precast panels, or shotcrete. In this system, soldier piles function as permanent or temporary structural members resisting earth pressure.

- Formwork Soldier: A temporary works component used exclusively to support concrete formwork and removed after the concrete has gained sufficient strength.

The key distinction lies in their function: one resists soil pressure, while the other resists the pressure of fresh concrete. Confusing these terms can lead to serious design and procurement errors.

The Physics of Formwork: Why Soldier Design Matters

The performance of a formwork soldier is governed by a fundamental physical principle: resistance to hydrostatic pressure. Fresh concrete behaves like a fluid, exerting lateral pressure on formwork panels that increases linearly with pouring height and reaches its maximum at the base. This pressure can reach several tons per square meter, generating enormous bending forces on panels and horizontal walers.

This is where engineered soldier design becomes critical. Soldiers are typically fabricated from two welded U-shaped steel channels, forming a section with a high moment of inertia. The moment of inertia represents a section’s resistance to bending; the higher it is, the lower the deflection under a given load. A high moment of inertia ensures that the soldier can carry heavy loads without excessive bending, thereby preserving dimensional accuracy and surface quality of the final concrete. This engineering feature fundamentally distinguishes a standard formwork soldier from generic steel profiles.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.