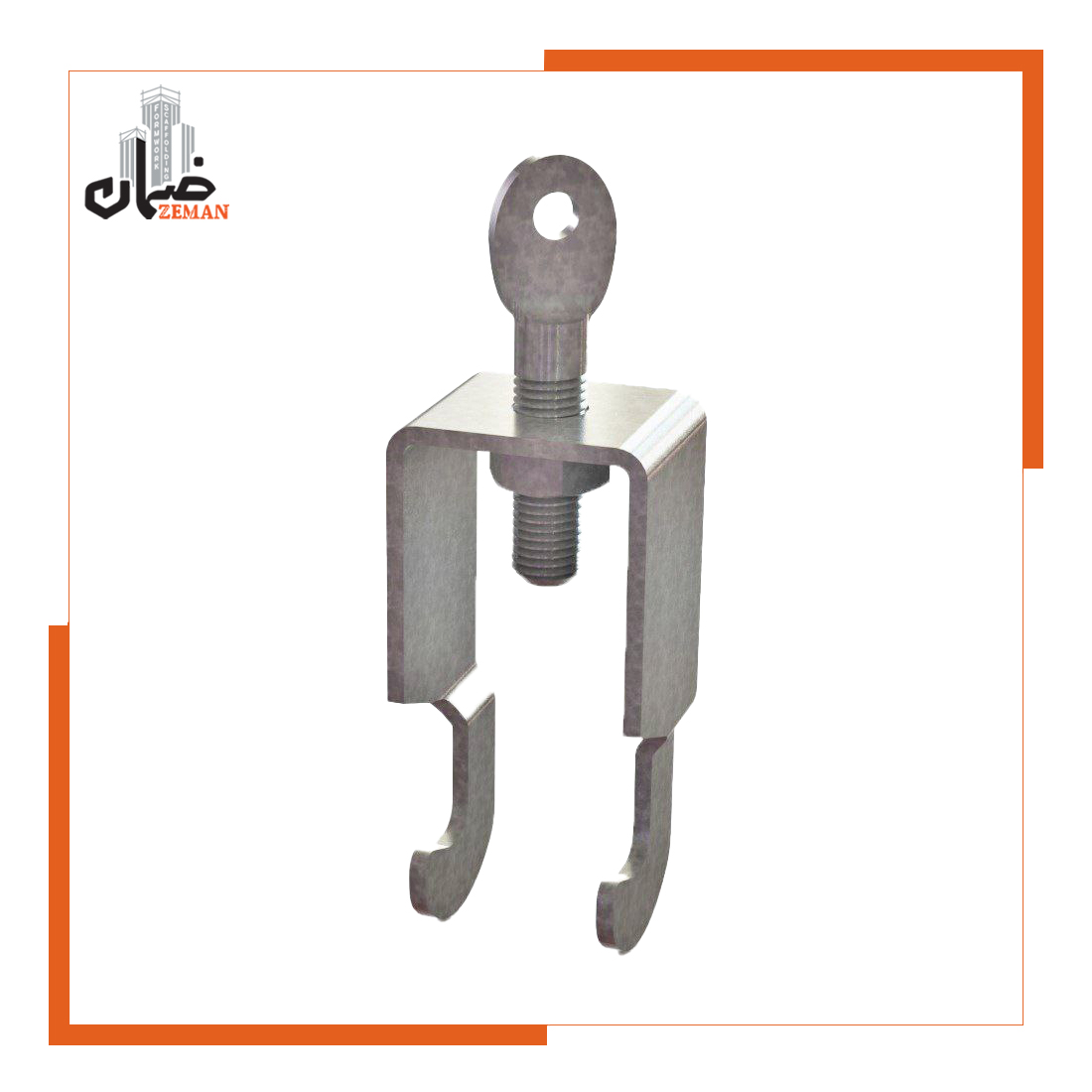

Formwork Clamp

The formwork clamp is one of the essential and widely used components in concrete formwork systems, designed to connect and secure metal formwork panels to one another. These clamps are commonly used to increase structural rigidity, prevent formwork separation, and significantly accelerate the assembly of formwork operations.

Types of Formwork Clamps

- The wing‑nut formwork clamp is the most commonly used type of formwork clamp. It is employed to create a secure connection between the soldier and the formwork panel, or between the formwork and the waler. This type is manufactured in two standard sizes: medium and heavy‑duty.

- The bull‑head clamp (U Clamp) is used to connect the soldier to the formwork panel or to the shoring jack. It offers high resistance against lateral concrete pressures.

Formwork Clamp

Introduction: The Silent Guardian of Concrete Structures

At the core of every major concrete structure—from urban skyscrapers to heavy-duty bridges—there are unsung components that ensure strength, accuracy, and long-term stability. The formwork clamp is one of these critical elements. Known in the construction industry by various names such as formwork clip, formwork clamp, goat-horn clamp, or double-leg clamp, this component is regarded as one of the key connections in metal concrete formwork systems.

The primary challenge during concrete placement is restraining the massive hydrostatic pressure of fresh concrete—a force capable of deforming or separating formwork panels. The formwork clamp serves as a vital connector, firmly fastening formwork panels to walers and braces (horizontal and vertical reinforcing members), thereby controlling this destructive pressure. This comprehensive guide assists contractors, project engineers, and procurement managers in selecting, purchasing, and properly using the most suitable formwork clamp to ensure safety, quality, and productivity across their projects.

Engineering the Formwork Clamp: Functional Performance and Strategic Importance in Project Safety

The role of a formwork clamp extends far beyond that of a simple fastener; it is an engineered component designed to resist substantial physical forces. Its U-shaped body combined with an adjustable screw provides an efficient mechanical system that generates the compressive force required to lock walers securely against the formwork panel. This function becomes critically important when resisting concrete hydrostatic pressure.

Fresh concrete behaves like a heavy fluid, exerting increasing pressure on formwork walls as the concrete height rises. Acting as the first and most important line of defense, the formwork clamp prevents joint separation, panel deformation, and ultimately, complete formwork failure.

Neglecting the importance of quality in this component can lead to catastrophic consequences. Failure of a single clamp can trigger a chain reaction resulting in multiple risks:

- Technical Risks:

Permanent deformation of the concrete structure, formation of uneven and wavy surfaces requiring costly remediation, and concrete leakage (grout loss) that severely compromises structural and surface quality. - Financial Risks:

Significant costs associated with demolition and re-execution of defective sections, substantial waste of materials (concrete and reinforcement), and serious delays to the overall project schedule. - Safety Risks:

The most critical consequence is sudden and complete formwork collapse, which may result in severe or fatal accidents for personnel on site.

Therefore, a formwork clamp is not a simple consumable item but a vital engineered component essential to ensuring project safety and stability. Selection must be based on sound technical analysis and risk assessment rather than initial purchase price alone. This decision represents a direct investment in the quality and safety of the entire structure.

Types of Formwork Clamps: Selecting the Right Tool for Each Application

Choosing the appropriate clamp is not an isolated decision; it is directly linked to the engineering design of the waling and bracing system. The waler system (including pipes, channels, or box sections) is designed based on applied loads and project requirements, and the clamp must be selected accordingly in order to achieve a safe and efficient connection. The main clamp types and their specific applications are described below.

Medium Formwork Clamp (Pipe-to-Formwork Clamp)

The medium clamp is recognized as the most commonly used clamp type in construction projects.

- Primary Application:

Designed to connect horizontal scaffold pipes used as walers to metal formwork panels. - Technical Specifications:

This clamp has a standard length of 12 cm and is designed to secure pipes with a maximum diameter of 60 mm. - Typical Use Case:

In a concrete wall formwork project, after panels are connected using pins and wedges, scaffold pipes are placed horizontally behind the panels to maintain alignment and resist concrete pressure. The medium clamp firmly secures these pipes to the formwork panels.

Long Formwork Clamp: Designed for Heavy Loads and Specialized Profiles

When higher structural strength is required within the waling system, stronger profiles are used, necessitating a compatible clamp.

- Primary Application:

Mandatory when horizontal or vertical walers are constructed from steel profiles such as channels or box sections rather than pipes. - Technical Specifications:

With a standard length of 18 cm, the long clamp offers a wider opening, allowing it to securely grip larger and heavier-duty steel profiles. - Typical Use Case:

In high concrete walls or heavily loaded structures where concrete pressure is substantial, engineers employ channel sections as walers. In such cases, only the long clamp can provide a proper and safe connection between the formwork and this type of waler.

Pipe-to-Pipe Formwork Clamp: Specialist for Cross Connections and Increased Rigidity

This type of clamp is designed to enhance the integrity and stiffness of the waling network.

- Primary Application:

Intended for connecting two scaffold pipes either parallel or perpendicular (crosswise) to each other. This connection is particularly critical at intersections of pipe walers where a rigid support grid is required. - Technical Specifications:

While similar in overall size to the long clamp (approximately 18 cm), this clamp features elongated hooks with specialized curvature to safely and simultaneously enclose two pipes. - Typical Use Case:

Most commonly used in column formwork and tall wall systems, where connecting horizontal and vertical pipes creates a robust support framework that effectively prevents any displacement or distortion of the formwork system.

To assist in selection, the following table provides a comprehensive comparison of the different clamp types:

| Formwork Clamp Type | Primary Application | Compatible Waler Type | Standard Length | Typical Use Case |

|---|---|---|---|---|

| Medium Clamp | Connects horizontal walers to formwork | Scaffold pipe | 12 cm | Standard wall and foundation formwork |

| Long Clamp | Connects horizontal/vertical walers to formwork | Channel, box section | 18 cm | High walls and high-pressure concrete structures |

| Pipe-to-Pipe Clamp | Connects two pipes together | Scaffold pipe | 18 cm | Improved waler grid integrity in columns and walls |

Decoding Technical Specifications: A Buyer’s Guide to Identifying Quality Formwork Clamps

Evaluating the quality of a formwork clamp requires close attention to technical details that directly affect performance, durability, and safety. Informed buyers can distinguish reliable products from high-risk alternatives by understanding these parameters.

Steel Plate Thickness: Why 5 mm Is the Industry Gold Standard

The thickness of the steel plate used in manufacturing a clamp is the most critical physical indicator of its strength. Three common thicknesses exist in the market: 4 mm, 5 mm, and 6 mm.

- 4 mm Clamp:

Considered an economical option, but offers lower resistance to pressure and a shorter service life. - 6 mm Clamp:

Although extremely strong, it is less commonly used due to higher cost and excessive capacity for most standard construction applications. - 5 mm Clamp:

Regarded as the optimal balance (sweet spot) and the professional standard. Five-millimeter clamps provide sufficient strength to resist concrete pressure in most conventional projects, offer high durability and reusability, and are typically only marginally more expensive than 4 mm alternatives. These advantages have established 5 mm thickness as an informal industry benchmark for quality and reliability.

Material Composition: Steel vs. Cast Iron

- Steel:

High-quality steel is the standard material for formwork clamp production. Its high tensile strength and adequate ductility make it ideal for withstanding construction-site impacts and mechanical stresses. - Cast Iron (Ductile Iron):

While certain formwork components—such as wing nuts—are manufactured from ductile cast iron due to its excellent compressive and wear resistance, steel remains superior for clamp fabrication because of its flexibility and improved resistance to tensile and bending forces.

Critical Design and Manufacturing Details

- Bolt and Thread Quality:

The bolt, typically 16 mm in diameter, must be made from high-strength steel. High-quality threading ensures smooth tightening, secure fastening, and resistance to thread stripping after repeated use. - Surface Coating:

To protect against corrosion and rust in wet and aggressive jobsite environments, clamps should be finished with protective coatings such as galvanizing or oven-baked paint. - Load Capacity:

Each clamp is rated for a specific load capacity (generally in the range of 500 to 2,000 kg), indicating the maximum force it can withstand without deformation. This quantitative parameter is a key factor in engineering evaluation and safety assurance.

Execution Guidelines: Proper Installation and Use of Formwork Clamps on Site

Ease of use must not lead to carelessness. Correct and methodical installation of formwork clamps is essential to ensure proper system performance and overall site safety.

Step-by-Step Installation Guide

- Preparation: First, metal formwork panels are positioned adjacent to one another and connected using pins and wedges.

- Waler Placement: The waler (pipe, channel, or box section) is positioned at the designated location behind the panels.

- Clamp Installation: The clamp is placed over the waler from behind, and its front hooks are inserted into the pre-formed holes along the formwork panel edges.

- Tightening: Using a suitable wrench, the clamp’s threaded bolt is tightened until the waler is fully secured against the formwork with no looseness.

- Final Inspection: Before concrete placement begins, all clamps must be visually and physically inspected to ensure correct installation and secure fastening.

Common Mistakes and How to Prevent Them

- Using an inappropriate clamp:

Installing a medium clamp on a channel-section waler creates a weak and extremely hazardous connection due to poor compatibility. - Over-tightening or under-tightening:

Excessive force may damage threads, while insufficient tightening fails to achieve a secure connection. - Improper clamp spacing:

Uneven distribution of clamps creates weak points within the concrete formwork system. As a general guideline, the use of four clamps per square meter of formwork surface is recommended; however, final spacing must be approved by the project engineer.

Safety Checklist

- Always use appropriate personal protective equipment (PPE), including safety gloves and protective eyewear.

- Before each use, inspect formwork clamps for cracks, bending, or severe corrosion.

- Ensure that bolt threads are clean to allow proper tightening.

- Use the correct wrench for final tightening. Striking the bolt handle with a hammer is an improper practice that can damage the bolt and prevent accurate clamping force.

Strategic Procurement: Looking Beyond Price Toward Value and Partnership with Zeman

Purchasing construction equipment such as formwork clamps is a strategic decision that must focus on long-term value and safety rather than initial cost alone.

Key Factors Affecting Formwork Clamp Pricing

The final price of a clamp is influenced by several factors:

- Raw Material Costs: Fluctuations in global and domestic steel prices directly affect manufacturing costs and final product pricing.

- Thickness and Weight: Clamps with greater thickness and weight require more raw materials and therefore have a higher price.

- Manufacturing Quality and Brand:

Reputable manufacturers that implement strict quality control processes and use premium raw materials offer products at higher prices but with significantly greater reliability. - Order Volume:

Bulk purchasing typically results in lower unit pricing.

Total Cost of Ownership (TCO): Why Cheap Clamps Cost More

Focusing solely on the initial purchase price is a common mistake. Professional buyers evaluate the total cost of ownership (TCO).

- Service Life and Reusability:

A high-quality clamp manufactured from 5 mm steel plate can be reused across numerous projects. In contrast, an inexpensive 4 mm clamp may deform after one or two projects, requiring replacement and driving up long-term costs. - Reduction of Hidden Costs:

More importantly, quality clamps significantly reduce the risk of formwork failure, rework, material waste, and project delays. These hidden costs far exceed the initial price difference between standard and low-cost clamps. - Residual Value:

High-quality clamps retain better resale value in the secondary market, helping recover part of the initial investment.

Why Choose Zeman as Your Formwork Clamp Supplier?

- Commitment to Quality Standards:

Zeman’s production standard for formwork clamps is the use of 5 mm steel plate, ensuring strength, durability, and safety across all projects. - Strict Quality Control:

All products undergo rigorous inspection from raw material selection through final testing to ensure defect-free delivery. - Competitive and Transparent Pricing:

By supplying directly from the factory and eliminating intermediaries, Zeman guarantees the best value relative to the quality provided. - Expert Technical Support:

Zeman’s technical specialists are available to provide professional consultation, ensuring clients select the most suitable equipment based on exact project requirements.

The Integrated Formwork System: The Clamp as Part of a Larger Whole

Optimal performance of a formwork clamp depends on the compatibility and quality of all other elements within the formwork system. The clamp does not function in isolation but as part of an integrated ecosystem of connections, each playing a vital role.

- Pin and Wedge:

These components provide the primary connection between formwork panels, forming the basic structure of the formwork wall. - Tie Rod and Wing Nut:

In double-sided wall formwork, tie rods restrain concrete pressure and maintain precise spacing between opposing formwork faces, while wing nuts secure this connection. - Double-Pipe Washer and Plate Washer:

These washers distribute tie-rod forces evenly onto walers and prevent localized damage. - Soldier:

In large-scale projects and very tall wall systems, soldiers are used as heavy-duty vertical walers to significantly enhance the overall strength and stiffness of the formwork system.

Only through the integrity and high quality of all these components working together can a safe, accurate, and efficient formwork system be achieved.

Conclusion: Build with Confidence

A formwork clamp is far more than a metal accessory; it is a critical component in structural engineering and a key safeguard for jobsite safety. Understanding the essential differences between clamp types (medium, long, and pipe-to-pipe) and selecting the appropriate option based on waler system design is the first step toward successful execution. Emphasizing the 5 mm industry standard and adopting a value-based, total cost of ownership (TCO) approach rather than focusing solely on initial price represents a professional strategy that protects projects from technical, financial, and safety risks.

To receive free technical consultation, obtain accurate pricing, and place an order for your next project, contact Zeman’s technical experts and construct durable, reliable structures with complete confidence.

Frequently Asked Questions (FAQ) about Formwork Clamps

How many formwork clamps are required per square meter?

On average, four formwork clamps are required per square meter of formwork surface. However, this is a general estimate, and the exact number must be determined based on factors such as concrete placement height, concrete type, and approval of the supervising project engineer.

What is the main difference between medium and long formwork clamps?

The primary difference lies in the type of waler they are designed to secure. Medium clamps are intended for pipe walers, while long clamps are used to connect channel

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.