Facade Wall Formwork

In the construction of tall concrete structures such as walls, tanks, and dams—where climbing formwork systems are employed—brackets are used as the primary structural component of the system. In one-sided climbing applications, the bracket withstands all loads resulting from the weight of the formwork, concrete pressure, and worker loads, and based on its truss-like structural behavior, transfers these vertical forces horizontally to the anchor bolts embedded in the concrete wall of the previous construction stage.

Brackets can be used at any height, eliminating the need for scaffolding to transfer gravitational loads to the ground. Due to this advantage, bracket systems offer significant economic and operational benefits in the formwork of high-rise structures compared to alternative methods. The bracket provides a temporary yet stable working platform that serves as a reliable support for formwork installation while also creating sufficient space for formwork operations and precise plumb adjustment. The bracket is connected to the concrete structure by means of bolts or anchor bolts, and after each concreting stage, the bracket—either together with the formwork or independently—is lifted by crane and relocated to a higher level.

Facade Wall Formwork

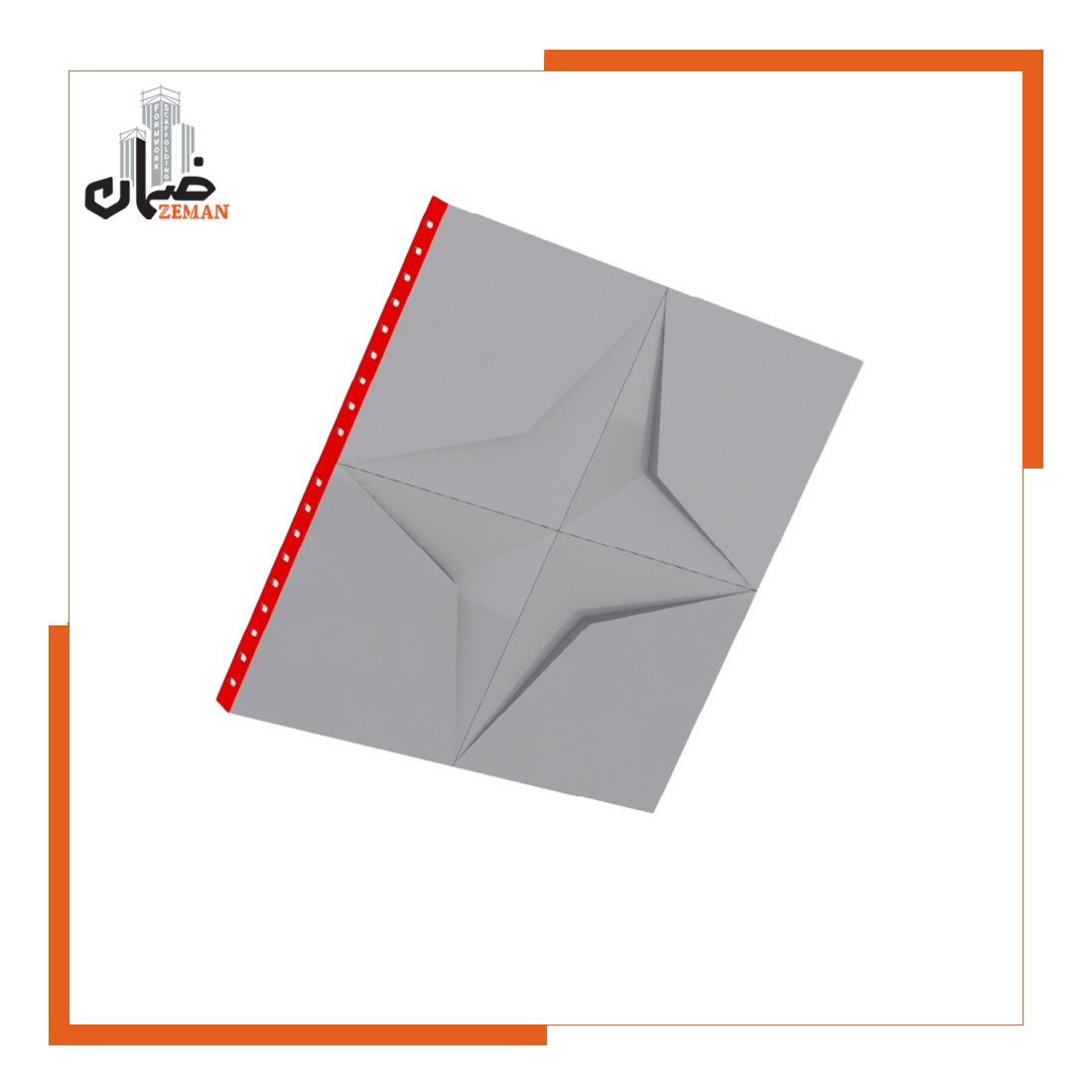

Facade wall formwork is one of the key stages in the execution of concrete structures and is of particular importance in projects such as high-rise walls, tanks, silos, and dams. The purpose of facade wall formwork is to create a smooth, durable, and precise surface for concrete placement, ensuring not only structural strength but also compliance with architectural and aesthetic standards. In tall structures, the use of climbing formwork systems increases execution speed, enhances safety, and reduces ancillary costs.

A facade wall is not only a critical part of the structural framework but also has a direct impact on the visual appearance and architectural identity of a building. To achieve a smooth, uniform, and defect-free concrete surface, proper selection and execution of facade wall formwork are essential. This process must be carried out in such a way that, after stripping the formwork, the concrete surface requires minimal finishing and repair, ensuring the final quality of the work.

What Is Concrete Facade Wall Formwork?

Concrete wall formwork is a specialized construction process in which fresh concrete is shaped using steel, timber, or composite formwork systems, ensuring that the final wall fully complies with execution drawings and project standards in terms of dimensions, angles, and surface quality. In facade wall formwork, attention to detail is of utmost importance, as even minor defects at this stage can negatively affect the appearance, aesthetics, and integrity of the building facade. Proper selection and correct installation of formwork guarantee the final quality and long-term durability of the concrete facade.

Concrete wall formwork is one of the most critical and sensitive stages in the construction of reinforced concrete structures, as these walls are responsible for carrying dead loads as well as vertical and lateral forces. Even minor errors in reinforcement placement or concrete pouring can lead to serious structural failure. In this article, you will become familiar with various methods and systems of wall formwork, enabling you to construct a safe and high-quality structure.

Wall formwork systems consist of a set of prefabricated components that are temporarily used to shape and support concrete during execution. These systems are available in various types, each suitable for specific project conditions and construction requirements.

In practice, concrete wall formwork can be considered a form of temporary scaffolding used for wall construction, significantly increasing execution speed. By using reusable concrete panels, this method allows the construction of walls with different thicknesses. Wall formwork systems offer numerous advantages, including increased execution speed and precision, higher construction quality, improved safety, reduced material waste, and the capability to implement complex designs.

Types of Facade Wall Formwork

In facade wall formwork execution, selecting the appropriate type of formwork plays a crucial role in project quality, speed, and cost. Common types of facade wall formwork include:

Metal (Modular) Formwork

- Manufactured from steel sheets with a robust profiled frame

- High dimensional accuracy and reusability across multiple projects

- Suitable for large-scale projects and the execution of smooth, uniform, and joint-free facades

Timber (Traditional) Formwork

- Constructed using softwood planks or waterproof plywood panels

- High flexibility for forming curves and architectural details

- An economical option suitable for small projects or complex facade geometries

Composite or Plastic Formwork

- Lightweight and easy to install compared to metal formwork

- High resistance to moisture, corrosion, and adverse weather conditions

- Ideal for areas requiring lightweight, mobile, and fast-installation formwork

Wall Formwork Methods

In wall formwork systems, various execution methods are used, each with its own advantages and limitations. Selecting the appropriate method depends on factors such as wall height, structural type, budget, and equipment availability. The three most common wall formwork methods include:

Conventional Method

In this method, formwork panels are held together using clamps and spacers. Props or timber supports are used to ensure vertical alignment. After concrete placement, the ties may either remain in place with protruding parts cut off or be completely removed from the concrete.

Climbing Formwork Method

This method is suitable for high-rise walls. Formwork is installed in stages; after each concrete pour and initial setting, the formwork panels are stripped and the bolts are removed. Brackets are then installed using the remaining bolt holes, and the next upper section is formed. This cycle continues until the wall concreting is completed.

Slipform Method

This wall formwork method is mechanized and requires less manpower compared to other techniques. After each concreting stage, the formwork panels are lifted using hydraulic jacks, and the next stage begins. Alignment and leveling are achieved through adjustable screws mounted on the brackets.

Stages of Facade Wall Formwork Execution

Proper execution of facade wall formwork requires strict adherence to precise and standardized steps to achieve a smooth and durable surface and to prevent surface defects in concrete. The main stages include:

Site Preparation

- Cleaning, leveling, and smoothing the base surface

- Installing reinforcement according to execution drawings and ensuring its stability

Assembly and Installation of Formwork

- Connecting formwork panels using clamps, fasteners, or bolts and nuts

- Careful checking of plumbness and alignment to prevent deviation or deformation

Formwork Sealing

- Using sealing tapes or joint compounds to prevent cement slurry leakage

- Ensuring all connections between panels are fully sealed

Oiling the Inner Surface of Formwork

- Applying appropriate form-release oil to prevent concrete adhesion

- Facilitating easy stripping without damaging the concrete surface

Concrete Placement and Compaction

- Placing concrete in uniform layers

- Using vibrators to compact concrete and prevent air voids on the facade surface

Formwork Stripping

- After the concrete reaches its initial strength (typically 24 to 48 hours)

- Careful removal of formwork to avoid edge chipping and surface damage

Climbing Formwork and Bracket System

In facade wall formwork, climbing formwork systems are among the most modern and efficient methods, particularly suitable for high-rise structures. In this system, brackets act as the primary component, serving as a strong temporary support for both the formwork and the working platform. Brackets are installed at various heights and are relocated step by step as construction progresses.

In one-sided climbing formwork, the bracket bears all loads arising from the formwork weight, lateral pressure of fresh concrete, and worker loads. Through its truss-like action, these vertical forces are transferred horizontally to anchor bolts embedded in the previously cast concrete.

A key advantage of bracket systems is the elimination of ground-supported scaffolding, resulting in reduced costs, enhanced safety, and a more open working area.

Advantages of Using Brackets in Facade Wall Formwork

- Cost efficiency: elimination of scaffolding and reduction of temporary equipment

- Increased execution speed: rapid lifting of brackets and formwork to higher levels using a crane after each pour

- High safety level: provision of a stable and secure working platform

- Accurate formwork adjustment: sufficient space for precise alignment and plumb control

- High flexibility: suitability for installation at any height and on various concrete geometries

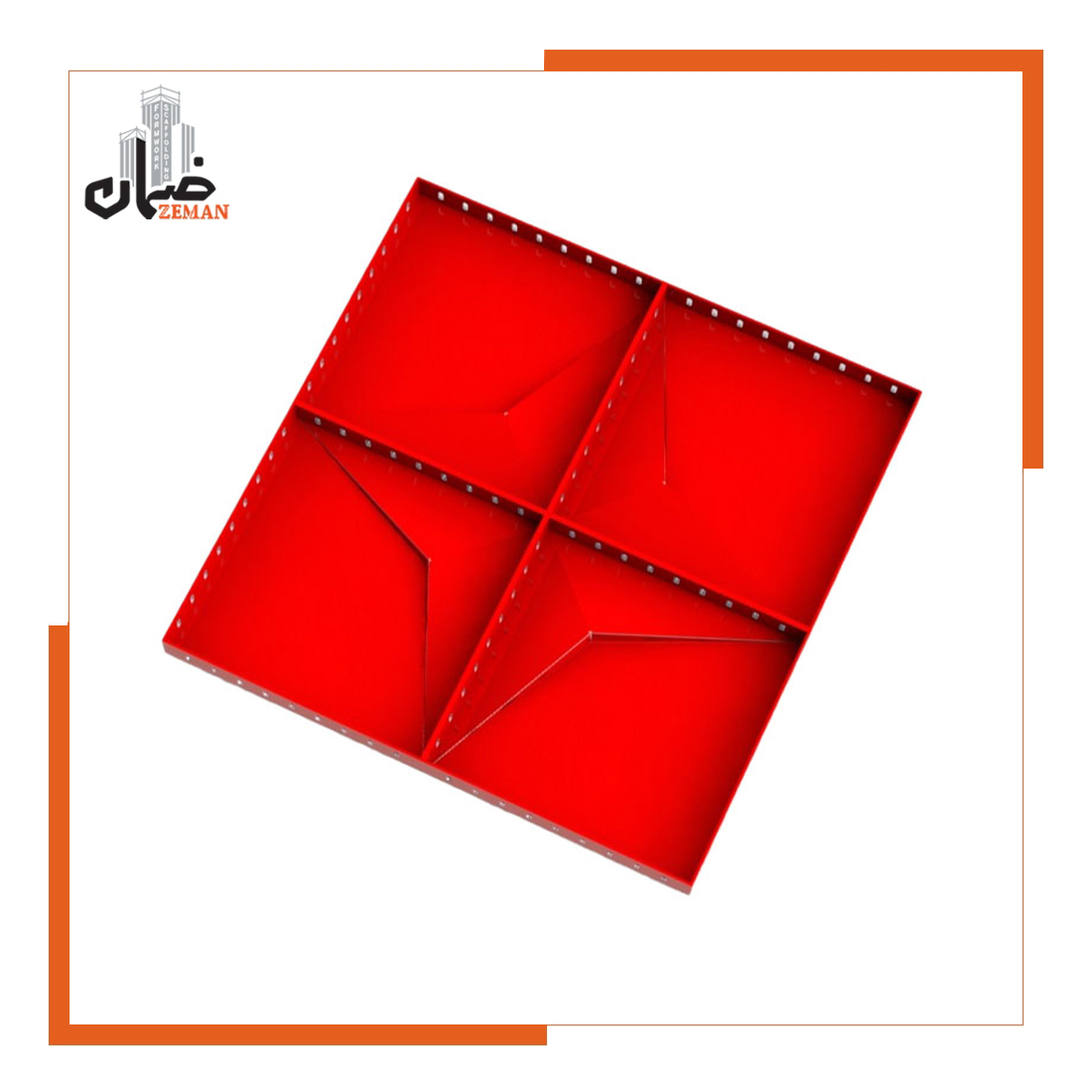

Main Components of the Bracket System

- Connection plate: interface between the bracket and anchor bolts

- Truss arm: primary load-transferring member

- Working platform: area for workers and equipment during formwork operations

- Locking and anchoring system: stabilizes the bracket and prevents unintended movement

Installation and Relocation Steps of Brackets in Facade Wall Formwork

- Installing anchor bolts during the previous concrete pour

- Fixing the bracket to anchor bolts using high-strength bolts or nuts

- Mounting the formwork on the bracket and ensuring proper alignment

- Placing concrete and waiting for it to gain sufficient strength

- Lifting and relocating the bracket and formwork to the next level using a crane

Execution and Safety Considerations in Facade Wall Formwork

For safe and proper execution of facade wall formwork, strict adherence to technical and safety requirements is essential. Before each concrete pour, all bracket and formwork connections must be thoroughly inspected and tightened, and overloading beyond the allowable capacity of the brackets must be avoided. The use of personal protective equipment, such as safety harnesses, is mandatory. In exposed concrete facades, the cleanliness, smoothness, and integrity of formwork surfaces play a critical role in the final appearance.

Additionally, using undamaged and smooth formwork panels, observing appropriate stripping times, precise control of bracing systems to resist hydrostatic concrete pressure, application of suitable form-release agents without adverse effects on concrete color and texture, and prior planning of openings and expansion joints are among the key factors in achieving a uniform, durable, and defect-free concrete facade.

In facade wall formwork, modular formwork systems are generally used, and in some cases, special formwork is applied. The execution method varies depending on project conditions and the type of structure.

These methods are particularly suitable for tall concrete structures such as walls, tanks, and dams and must be capable of supporting formwork weight, concrete pressure, and worker loads in one-sided climbing conditions. Vertical concrete loads are transferred horizontally to anchor bolts embedded in the wall of the previous stage, allowing the formwork to operate at any height without ground-supported scaffolding.

Advantages and Importance of Proper Facade Wall Formwork Execution

Proper execution of facade wall formwork plays a vital role in the final quality of the structure. By using correct formwork systems, a smooth and uniform concrete surface is achieved, significantly reducing the need for post-concreting finishing and repair. Accurate facade wall formwork also increases the service life of the facade and prevents moisture penetration and cracking. The use of modern formwork systems enhances execution speed and substantially reduces repair and painting costs.

Comparison Table of Facade Wall Formwork Methods

| Comparison Criteria | Scaffold-Based (Traditional) Formwork | Climbing Formwork with Brackets | Slipform System |

|---|---|---|---|

| Execution Speed | Medium (due to scaffold assembly and dismantling) | High (rapid crane-assisted bracket relocation) | Very High (continuous formwork movement) |

| Equipment Cost | Medium to High (scaffolding and accessories) | Medium (brackets and anchor bolts) | High (mechanized system and specialized equipment) |

| Work Safety | Medium (risk of falling from scaffolding) | High (stable working platform) | High but requires skilled personnel |

| Concrete Surface Quality | Good | Very Good (precise plumb control) | Good to Moderate (due to high speed) |

| Suitability for Great Heights | Limited | Unlimited | Unlimited |

| Facade Design Flexibility | Moderate | High | Low |

| Need for Extensive Side Space | Yes | No | No |

| Best Suited For | Small to medium-sized projects | High-rise projects requiring high precision | Tall structures with continuous concreting |

Facade Wall Formwork at Zaman Company

By leveraging extensive experience and modern equipment, Zaman Company executes facade wall formwork in accordance with the highest quality standards. Using modular and special formwork systems, Zaman’s expert team is capable of constructing various concrete walls with different heights and architectural facade designs with exceptional accuracy and efficiency.

The application of advanced formwork systems and safe brackets not only guarantees superior concrete surface quality but also reduces costs, saves time, and enhances overall project productivity. Through strict adherence to proper installation, sealing, and concrete placement principles, Zaman Company delivers a professional and reliable facade wall formwork solution for every project.

Conclusion: The Importance of Professional Facade Wall Formwork Execution

Facade wall formwork is a critical stage in concrete construction that ensures both structural strength and visual quality. Correct selection of formwork type, proper installation practices, precise sealing, and careful concrete placement are decisive factors in the final outcome of any project. Execution by a skilled team using standard equipment leads to significant time and cost savings and achieves a concrete surface of the highest quality.

Bracket systems in facade wall formwork, especially for high-rise structures, represent a modern, safe, and cost-effective solution. By eliminating the need for scaffolding and providing a stable working platform, these systems enhance both execution speed and accuracy. Proper use of brackets not only improves structural quality but also significantly increases overall project efficiency.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.