Curved Wall Formwork

Curved wall formwork is a distinct type of formwork executed in curved and circular shapes. For curved wall formwork, various systems such as curved (arched) formwork and modular concrete formwork are used. This type of formwork is commonly applied in the construction of circular walls in projects such as silos and storage tanks. Since the wall formwork is circular in geometry, in addition to concrete formwork panels, various auxiliary equipment is also required. Moreover, curved wall formwork demands a high level of execution skill, as its installation differs from conventional straight wall formwork and must be carried out with great precision to ensure an accurate circular final shape.

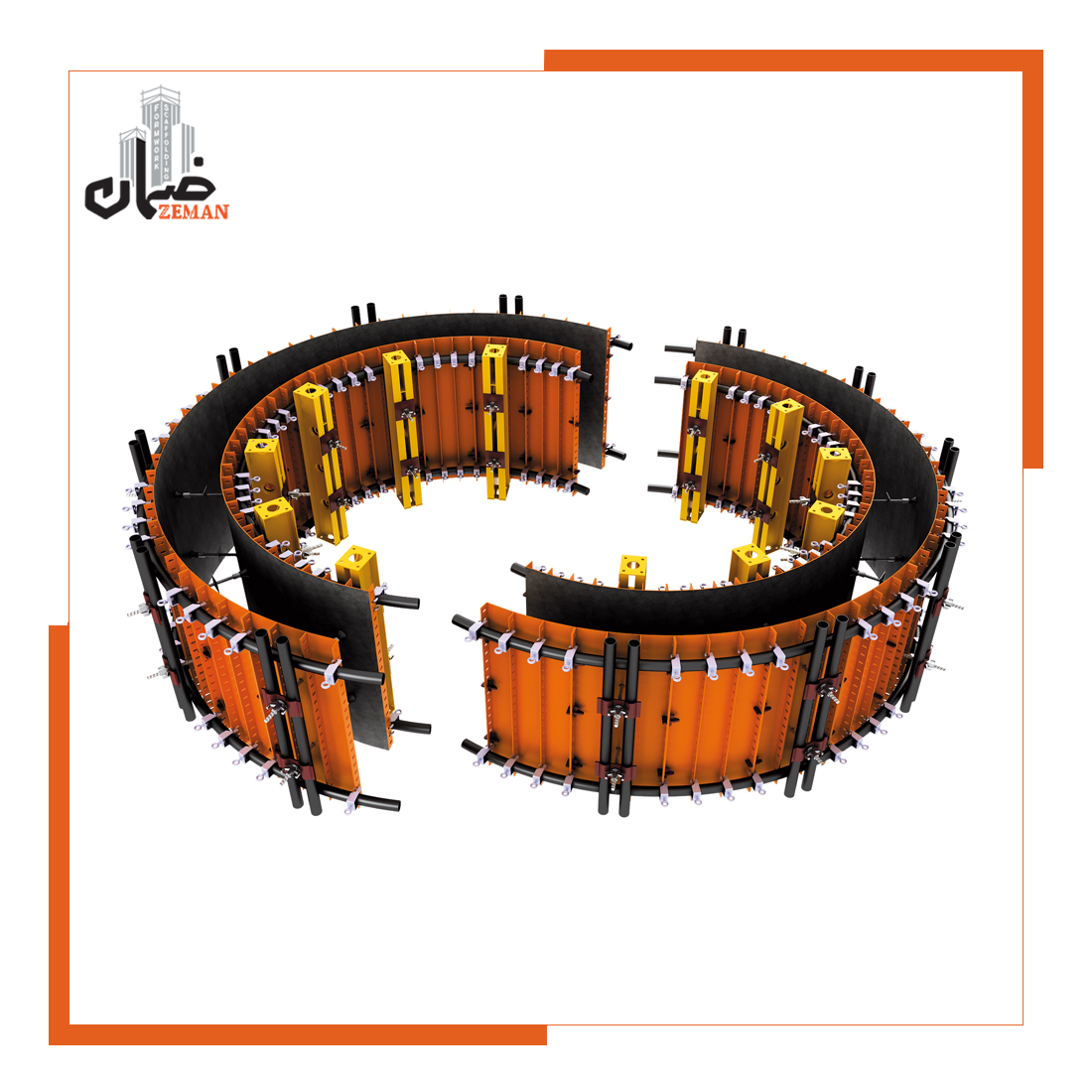

For the execution of circular structures with diameters greater than 2 meters, curved (arched) formwork panels are used. These panels are manufactured in various sizes and can be connected to other modular formwork systems. Depending on the required diameter, the panels follow their backing supports and adopt the appropriate curvature. These panels do not include horizontal perforated stiffening ribs and, based on the radius of the rolled tubes used as backing supports, various curvatures required for concrete placement can be achieved. The panels are secured to the rolled tubes using medium clamps.

Curved Wall Formwork

Curved wall formwork is one of the specialized stages in the execution of concrete structures and is used to shape, support, and maintain the curvature of concrete during the pouring process. Due to their curved geometry and specific form, such walls require precise and high-strength formwork systems capable of fully preserving the intended curvature and ensuring structural stability.

In curved wall formwork execution, selecting the appropriate formwork system is of great importance. Curved formwork must be designed to withstand the pressure and forces exerted by fresh concrete while accurately creating the desired geometry. The use of modular and adjustable formwork systems is a common and efficient approach in this process, enabling high precision, suitable execution speed, and cost efficiency.

When executing curved-section formwork with a large radius, scaffold tubes are first rolled to match the required curvature and then used as walers behind pre-assembled modular formwork panels. In cases where the curvature radius is smaller, curved (arched) formwork panels without transverse stiffening ribs are used instead of modular panels. Curved formwork is widely applied in the construction of concrete structures such as tanks, silos, and similar facilities.

Curved formwork panels are generally similar to standard concrete formwork, with the difference that they do not include the horizontal stiffening ribs found in modular concrete formwork. By adjusting the radius of the rolled tubes used as backing supports, various degrees of curvature can be achieved.

Curved formwork panels, similar to modular formwork, are manufactured in various dimensions and sizes and are connected to the rolled tubes using medium clamps. In curved or circular structures where the diameter is less than 2 meters—such as circular columns and concrete pipes—circular column formwork and circular or manhole formwork are used for concrete pipe construction.

What Is Curved Wall Formwork?

Curved wall formwork refers to the process of designing, manufacturing, and installing formwork systems used to shape walls with a defined curve or radius. This type of formwork is particularly applied in structures with curved, circular, or non-linear geometries, where conventional flat formwork systems are not capable of achieving the desired shape. In this method, the formwork must be constructed to accurately maintain the curvature and provide sufficient strength to retain fresh concrete until it reaches initial setting.

Curved Wall Formwork: Principles and Methods

Curved wall formwork is one of the most sensitive and specialized stages in the construction of circular and curved structures, commonly used in architectural and civil engineering projects such as large halls, bridges, circular tanks, and complex-designed buildings. In addition to their aesthetic value, these walls often play a critical structural role; therefore, strict adherence to technical principles in formwork selection, installation method, and precise curvature adjustment is essential. Due to their flexibility and fast installation, adjustable modular formwork systems are among the most widely used solutions for curved wall formwork.

Applications of Curved Wall Formwork

Curved wall formwork plays a crucial role in various civil and architectural projects by enabling the construction of robust and visually distinctive structures. Owing to its ability to accurately shape curved surfaces, this method is widely applied in different types of structures. Key applications include:

Traditional and Historical Architecture

In traditional and historical buildings such as mosques, churches, fortresses, and old bridges, curved wall formwork is used to restore or construct strong and aesthetically pleasing arches. These arches not only enhance visual appeal but also contribute to optimal load transfer within the structure.

Bridges and Tunnels

Due to the uniform distribution of stresses and the reduction of localized loads, arches play a vital role in the construction of bridges and tunnels. Curved wall formwork in these structures enhances stability and extends service life.

Modern and Artistic Structures

In contemporary architecture, curved wall formwork is used to create distinctive and visually appealing forms. Such designs add a unique character to both interior and exterior spaces.

Arched سقف and Vaulted Structures

Curved wall formwork can serve as the foundation for constructing arched or vaulted ceilings, offering significant advantages in both aesthetics and structural performance.

Creation of Flexible and Curved Spaces

In projects requiring open and fluid architectural layouts, curved wall formwork enables the creation of smooth lines and unique spatial volumes.

Reduction of Material Consumption

Thanks to optimal load distribution in curved structures, the use of curved wall formwork can, in certain cases, reduce material consumption and achieve economic savings.

Types of Concrete Formwork for Curved Wall Construction

For curved wall formwork, the formwork systems must be capable of accurately shaping curved and arched surfaces. Depending on the project requirements and the degree of curvature, two common types of concrete formwork are used:

1. Curved Formwork

Features: These formworks are specifically designed to create defined curvatures and can produce accurate arch shapes based on the required diameter and dimensions. They are typically manufactured from metal (steel or aluminum sheets) or bent timber, providing high resistance against concrete pressure.

Applications:

- Suitable for walls with fixed and repetitive curvature

- Used in projects where the curved shape is predefined and constant

Advantages:

- High accuracy in shaping and maintaining curvature

- Excellent strength and durability against concrete pressure

- Reusable, depending on the material

Disadvantages:

- Higher initial cost due to custom manufacturing

- Heavy weight and difficulty in transportation, especially for metal formworks

2. Modular Concrete Formwork

Features: These systems consist of smaller, standardized components that can be connected to create various curved and arched shapes. Their high flexibility allows for rapid modification of form geometry.

Applications:

- Suitable for projects with complex or variable curvatures

- Ideal for projects requiring frequent changes in form geometry

Advantages:

- High flexibility in creating diverse shapes

- Reduced fabrication cost due to standardized components

- Ease of transportation and installation

- Reusable and adjustable for multiple applications

Disadvantages:

- Lower accuracy compared to curved formwork in certain projects

- Requires skilled labor for precise installation and alignment

Importance of Curved Wall Formwork

Curved wall formwork is not only essential for achieving accurate geometry and curvature but also has a direct impact on the strength, durability, and final appearance of the wall. Using appropriate formwork improves concrete placement quality, reduces execution errors, and minimizes repair or reconstruction costs. In specialized projects, the choice between curved and modular formwork must be based on technical conditions, budget constraints, and structural design.

Materials Used in Curved Formwork

In curved wall formwork, the selection of formwork material plays a critical role in the overall quality and durability of the structure. Curved formworks are typically manufactured from steel, timber, or composite materials, each offering specific properties and applications. One of the most common types is curved (arched) formwork, which is generally used in projects with diameters greater than 2 meters. These formworks are produced in various dimensions according to project requirements and can also be connected to modular formwork systems.

Methods of Connecting Curved Formwork Panels

In curved wall formwork, the method of connecting panels is highly important, as it directly affects curvature accuracy and structural strength. In curved formwork systems, panels are typically connected to rolled scaffold tubes using medium clamps. This connection method allows the panels to be easily adjusted in different positions and ensures the desired curvature is maintained during concrete pouring.

Curved formwork panels are designed without horizontal perforated stiffening ribs and rely on rolled tubes as backing supports. This design provides high flexibility for projects with varying diameters and curvatures, while also enabling fast installation and execution.

Key Considerations in Curved Wall Formwork

Adhering to technical principles and selecting appropriate equipment play a vital role in the final quality of curved structures. Key considerations include:

Selection of Appropriate Formwork

The selected formwork must be capable of withstanding the weight of concrete and the pressures applied during pouring. In addition, the quality of materials used in formwork construction should be high to extend service life and prevent additional costs.

Accuracy in Curvature Adjustment

The curvature of the wall must be set strictly according to engineering drawings. The formwork should maintain this curvature and prevent any unintended deformation during concrete placement.

Structural Strength of Formwork

The strength of curved formwork systems is crucial; insufficient rigidity may lead to deformation and compromise the final quality of the wall.

Adjustability and Reusability

Adjustable modular formwork systems are an ideal choice for diverse projects. They allow modifications in dimensions and curvature and are economically efficient due to their reusability.

Selecting Concrete Formwork for Curved Wall Construction

Choosing the appropriate formwork for curved wall construction has a direct impact on concrete quality, curvature accuracy, and overall project cost. The main selection criteria include:

Wall Curvature Shape and Radius

- If the wall has a fixed and defined radius, curved formwork is the optimal option due to its high shaping accuracy.

- For complex, non-uniform, or variable curvatures, modular formwork systems offer better performance thanks to their flexibility.

Number of Reuses

- For large-scale or repetitive projects, reusable metal curved or modular formwork is cost-effective.

- For smaller or single-stage projects, timber or modular formwork offers faster and more economical execution.

Final Concrete Surface Accuracy

- Curved formwork produces smoother and more visually appealing concrete surfaces due to precise fabrication.

- Modular formwork may result in more joints, requiring additional finishing and surface treatment.

Weight and Ease of Installation

- Metal curved formwork is heavier and requires adequate labor and equipment for handling and installation.

- Modular formwork systems are lighter and quicker to install.

Total Project Cost

- Custom curved formwork has a higher initial cost but becomes more economical with repeated use.

- Modular formwork is more affordable due to standardized components and is suitable for various shapes.

Labor and Execution Expertise

Curved wall formwork requires skilled labor, particularly in modular systems where precise panel installation is critical to prevent defects during concrete placing.

Conclusion

Curved wall formwork is one of the most important stages in the construction of curved and arched concrete structures, contributing not only to aesthetic quality but also to structural strength and long-term durability. The selection of appropriate formwork—whether high-precision curved formwork or flexible modular systems—must be based on curvature radius, project type, budget, and the expertise of the execution team. Proper adherence to technical principles during installation and execution not only ensures high-quality concrete placement but also reduces costs and extends the service life of the structure.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.