Cross Head Slab Prop

Cross Head Slab Prop, widely known as the Cross Head Prop, is regarded as the gold standard among shoring props for the execution of modern floor systems such as concrete slabs and beam‑and‑block structures. The uniquely engineered cross‑shaped head is specifically designed to securely seat and lock various types of steel profiles, formwork soldiers, pipes, and engineered timber beams. This key feature not only significantly enhances the overall stability of the formwork system but also prevents lateral slippage, elevating construction site safety to the highest level.

Cross Head Slab Prop

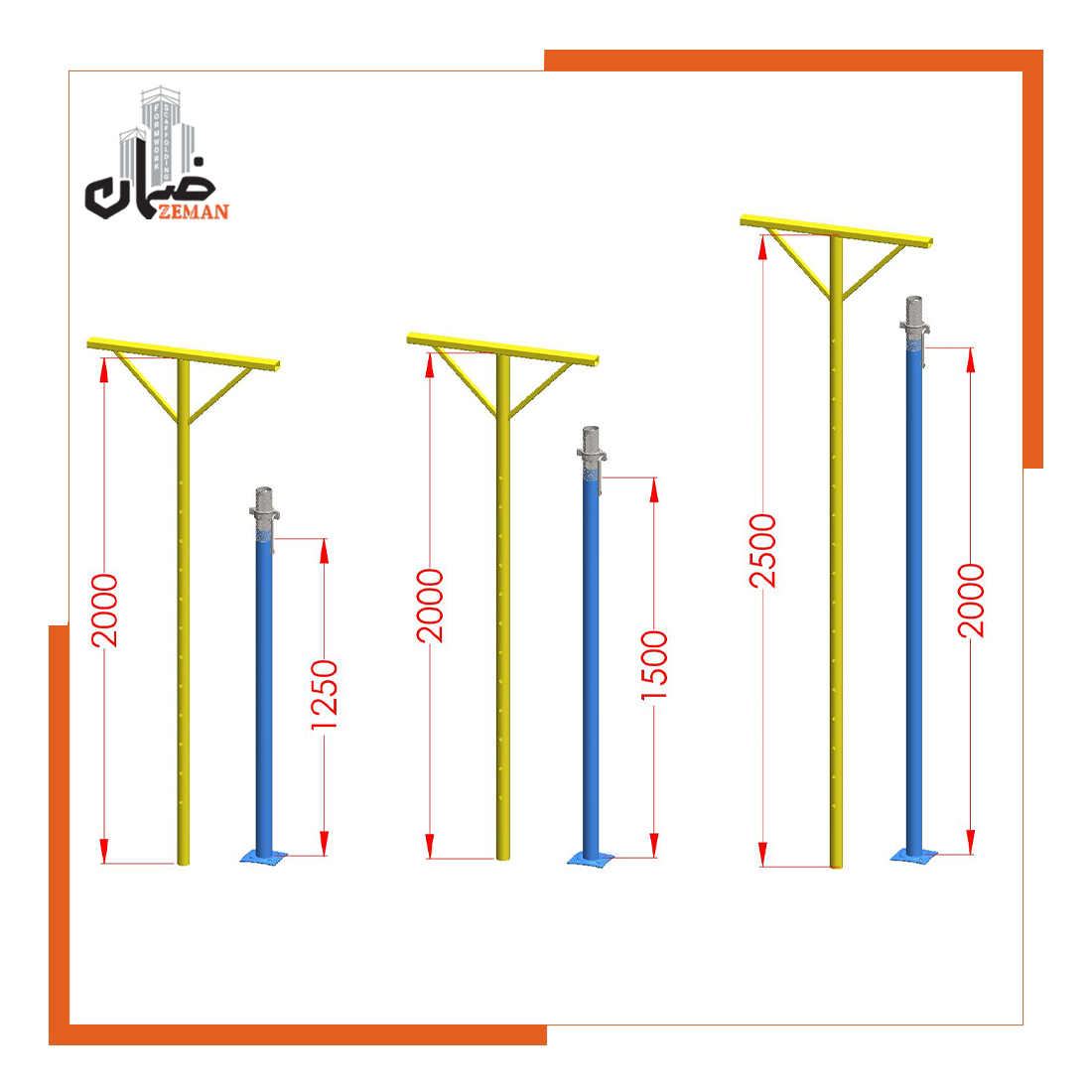

Cross Head Slab Prop (T-Head Prop)

The cross head slab prop (also known as a T‑head prop) is one of the key pieces of equipment used in construction projects for the temporary support of slabs and concrete formwork systems. Due to its specific engineered design, this type of prop is capable of carrying heavy loads and is widely used across various civil and building projects. At the top of the prop, a cross‑shaped (T‑type) head is installed, providing a larger contact surface with the slab formwork, which significantly enhances overall structural stability.

Cross Head Slab Props Consist of Two Main Components:

- Outer Tube (Female Tube):

Manufactured from a steel tube with an approximate diameter of 60 mm, this section is equipped with a threaded portion that allows precise height adjustment of the prop. - Inner Tube (Male Tube):

This tube is inserted into the outer tube and features a series of adjustment holes. The height of the prop is set using a pin or wedge placed through these holes.

Applications and Key Advantages of the Cross Head Prop

Using a cross head prop instead of a simple slab prop offers undeniable technical and safety advantages:

Applications:

- Primary and standard support system for beam‑and‑block slab structures

- Supporting steel profiles, pipes, and formwork soldiers

- Supporting timber beams and H20 wooden girders in modular formwork systems

Main Advantages:

- Exceptional Stability:

The cross head firmly holds the beams and profiles in place, preventing any lateral movement or slippage that could lead to serious safety hazards on site. - Increased Installation Speed:

Placing and positioning beams on cross head props is significantly faster and more secure than using simple flat‑head props. - Enhanced Safety:

The inherently safer design minimizes the risk of human error during formwork assembly and beam placement.

Competitive Advantages: Why Zaman Cross Head Props Stand a Step Above the Market

The true distinction of a high‑quality cross head prop lies in the manufacturing quality of its head and connection details. At Zaman Company, we manufacture this critical component with meticulous engineering precision:

- Reinforced Cross Head with Full‑Penetration CO₂ Welding:

The most critical part of this prop is its head connection. At Zaman Company, cross heads are fabricated from thick steel plates and fully welded to the inner tube using continuous, full‑penetration CO₂ welding. This integrated structure transforms what is typically the weakest point in low‑quality props into a major strength advantage. - Ductile Cast Iron Adjustment Nut:

The height‑adjustment nut is made of ductile (nodular) cast iron, offering far greater resistance to impact, compressive loads, and wear compared to conventional grey cast iron nuts. It does not crack or fail under heavy loads. - Use of Heavy‑Duty, Standard‑Grade Steel Tubes:

Unlike many manufacturers, we use heavy‑duty steel tubes with a thickness of 2.5 mm for both the inner and outer tubes. This significantly increases load‑bearing capacity and overall durability. - Available in Fixed and Adjustable Head Models:

We understand the diverse requirements of construction projects. Therefore, Zaman cross head props are available in both fixed cross models for flat slabs and adjustable (movable) cross head models for sloped slabs.

Technical Specification Table of Zaman Cross Head Prop

| Technical Specification | Standard Value |

|---|---|

| Standard Height | 3.5 m (custom sizes from 3 to 5 meters are available) |

| Prop Weight (Heavy‑Duty Model) | Approximately 14.5 kg |

| Head Type | Fixed Cross Head / Adjustable Cross Head |

| Cross Head Dimensions | 30 × 15 cm |

| Cross Plate Thickness | 4 mm |

| Tube Thickness | 2.5 mm (inner and outer tubes) |

| Nut Type | Ductile Cast Iron |

Price Inquiry and Purchasing Guide

Buy wisely: how to identify a high‑quality cross head prop.

When comparing prices, do not rely solely on the final number. Always ask the supplier to specify the exact weight of the prop and the welding method used for the cross head connection. A standard and safe cross head prop never comes with a low weight, and its welds must be continuous, clean, and fully integrated. Investing in Zaman’s heavy‑duty cross head props means investing in site safety and reducing long‑term project costs. For professional consultation and accurate pricing based on your order quantity, please contact our technical experts.

Frequently Asked Questions About Cross Head Props

1. What is the main advantage of a cross head prop compared to a simple slab prop?

Safety and stability. The cross head securely locks the beam or profile in place and prevents lateral slippage, which is one of the main on‑site risks. In contrast, simple slab props feature a flat plate, where beam slippage can occur.

2. When should an adjustable (movable) cross head prop be used?

Adjustable cross head props are ideal for sloped slabs, ramps, or any situation where horizontal beams are positioned at an angle relative to the prop. The adjustable head aligns itself with the beam angle, providing full and secure bearing support.

3. Are “T‑head prop” and “cross head prop” the same?

Yes. In the Iranian market, the terms “T‑head prop,” “cross head prop,” and “cross‑type prop” all refer to the same product and are used interchangeably.

4. What is the most important technical factor when purchasing a cross head prop?

The most critical factor is the quality and type of welding connecting the cross head to the inner tube. This joint must be a continuous, full‑penetration weld (preferably CO₂ welding). Props with spot welding or weak, uneven welds should be strictly avoided.

5. Are Zaman cross head props available in both light‑duty and heavy‑duty models?

Yes. To meet the needs of projects with different budgets, we manufacture both standard and heavy‑duty models. However, due to significantly higher safety and durability, we always recommend the heavy‑duty version as the best option.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.