Comprehensive Guide to Scaffolding Price and Purchase

This specialized guide provides a comprehensive overview of modern scaffolding systems (scaffold) and offers invaluable information for contractors and engineers. In this content, all major types of modular scaffolds—namely, Triangular, Hammer, and H-frame—are described in detail, with their applications, advantages, and technical specifications fully explained. If you are planning to purchase high-quality scaffolding, this information will help you to make an informed choice.

The economic analysis section explores the factors that affect scaffold prices, including raw material type, weight, pipe thickness, and market fluctuations. A strategic comparison between purchasing scaffolding and renting it is also provided to help contractors make project-based decisions. This analysis enables you to manage your project budget efficiently with a deeper understanding of scaffold prices and purchasing methods.

Understanding detailed technical features and specifications of scaffolding is as important as price analysis; therefore, we recommend reviewing the Ultimate Guide to Modular Scaffold for a comprehensive perspective on selection.

From Traditional Scaffolding to Modern Scaffold Systems

In the world of modern construction, safe access to heights and precise execution of engineering projects—ranging from facade operations on residential buildings to the construction of bridges and large infrastructures—are of vital importance. In the past, traditional scaffolding with metal pipes and clamps was used for these tasks, but their safety and stability were dependent on worker skill. Today, modular and engineered scaffolding systems (scaffold) have revolutionized the industry by replacing conventional scaffolding. If you are looking to purchase efficient and cost-effective scaffold, this guide familiarizes you with all system details.

A scaffold is a temporary metal structure designed with standard vertical, horizontal, and diagonal components, and assembled using pre-fabricated connections. This modular system simplifies, speeds up, and secures the installation process, minimizing human error. By choosing the right scaffold, you can guarantee rapid execution and enhanced project safety. This comprehensive guide will assist you to understand scaffold types, price-affecting factors, and the best purchasing options, empowering you to make smart and economical decisions for your projects.

Types of Scaffold and Specialized Applications

Due to their engineered design and pre-fabricated structure, modern modular scaffold systems play a key role in the execution of construction projects. The right type of scaffold directly impacts the safety, speed, and cost of the project. Here we introduce the main types of scaffold and their applications, to guide your purchasing decisions.

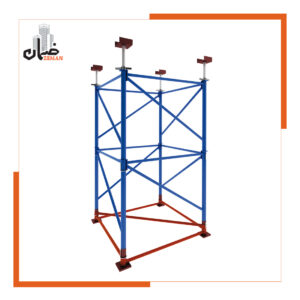

Triangular Scaffold: The Load-Bearing King

Triangular or shoring scaffold is one of the most popular types, designed with standard triangular frames and male-female connections. It does not require complex tools for assembly and can be installed by regular workers, saving time and cost. With a load capacity of up to 14 tons per square meter (with proper layout), it is ideal for formwork of concrete slabs, high ceilings, and bridge substructures. Components include 50, 75, and 100 cm frames, horizontal and diagonal braces, base plates, and adjustable heads. For triangular shoring scaffold purchase and pricing, consult authorized suppliers such as Zemanco.

Buy Triangular Shoring Scaffold

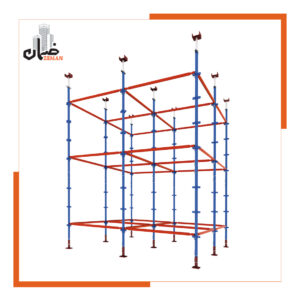

Speed and Flexibility with Hammer Scaffold

Hammer or ring scaffolding offers dramatically faster installation via simple hammer blows for connections. Available in Cuplock (cup-joint) and Starlock (star-ring) types, the absence of diagonal tubes makes worker access easier, making it suitable for facade work and temporary structure shoring. This system’s components include vertical posts (1–3 meters), horizontal braces (1–1.5 meters), and base plates. If you seek affordable hammer scaffold, this is an economic and efficient option.

H-Frame Scaffold: Unmatched Strength for Heavy Loads

H-frame scaffold, also known as H-formwork, uses pre-fabricated frames in the shape of the letter “H” made from thick steel tubes (30×60 mm), and is intended for heavy duty projects. With a load capacity up to 5.5 tons per box, it is ideal for bridge formwork, industrial roofs, and heavy foundations. High-speed assembly and male-female connections make it a popular choice.

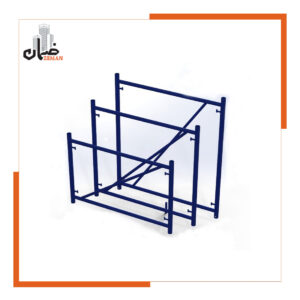

Service Scaffold: An Economic Solution for Facades

Service scaffold is a safe and economical alternative to traditional scaffolding. With stairway frames, X-frames, and metal decks, it is suitable for facades and building repairs. Fast installation and high safety make it an ideal option for lightweight projects.

To receive professional consultancy and learn the scaffold prices and purchase options, contact Zemanco and execute your projects with confidence.

Comparison Table of Modular Scaffold Types

| Scaffold Type | Main Application | Load Capacity (Approx.) | Key Advantages | Assembly Speed | Main Components |

| Triangular | Slab/Formwork for heavy slabs and bridges | Up to 14 tons/m² | Exceptional strength, no need for skilled labor | High | Triangular frames, braces, pins, adjustable jacks |

| Hammer | Facade, light formwork, temporary structures | Medium to high | Hammered quick assembly, high flexibility | Very high | Vertical posts, horizontal braces, cup/star lock |

| H-Frame | Bridge formwork, heavy industrial roofs | Up to 5.5 tons/box | Unique load capacity, integrated safety | High | H-frames, X-braces |

| Service | Facade works, maintenance | Medium | Economic, smart alternative to traditional scaffolding | Very high | Stairway frames, metal planks, caster wheel |

Comprehensive Guide for Scaffold Selection and Purchase

Choosing and purchasing scaffold for construction projects is a complex process that requires technical knowledge and a precise project needs assessment. This guide will help you make smart and economical decisions by evaluating your needs, comparing buying and renting options, and understanding price-affecting factors for scaffold.

Step One: Assess Your Project Needs

Before purchasing, carefully review your project requirements:

- Height and Dimensions: Determine the maximum height and workspace dimensions to select the appropriate type and number of frames or scaffold pipes.

- Required Loading: Calculate the live load (workers, tools, materials) and dead load (scaffold self-weight). For heavy-duty projects, triangular scaffold with high load capacity is recommended.

- Project Duration: For short-term projects, renting scaffold is more economical, but for long-term or high workload, purchasing is a better investment.

A thorough assessment helps you estimate the right price and select the most suitable scaffold.

Step Two: Buy or Rent? Economic Analysis

Deciding between purchasing or renting scaffold needs a cost-benefit analysis:

Benefits of Purchasing Scaffold

- Permanent Access: By purchasing, equipment is always available, with no need for rental coordination for every project.

- Long-term Savings: For companies with multiple projects, buying is more cost-effective compared to repetitive rentals.

- Customization: The ability to maintain and adjust equipment for project-specific needs.

Benefits of Renting Scaffold

- Low Initial Cost: Renting does not require high initial investment.

- No Maintenance Need: Service provider manages storage and repairs.

- Flexibility: Ability to choose different types of scaffold for each project.

For long-term projects, rental costs may exceed the price of buying scaffold. Transport costs for remote projects may also affect your decision. For pricing and comparing options, contact Zemanco.

Step Three: New or Used Scaffold? Safety First

New scaffold is always recommended for safety and quality. Used scaffold may suffer from rust, wear, or hidden defects compromising worker safety. Although the price of used scaffold is lower, safety risks and potential losses make it a nonprofessional choice. Always choose new scaffold from reputable providers such as Zemanco.

Factors Impacting Scaffold Price

The price of scaffold depends on several factors you must consider before purchasing:

Pricing Methods

- By Weight: Price is calculated per kilogram, common for direct equipment purchases.

- By Length or Month: For rentals or installation services, cost is based on length or rental period.

Determining Factors

- Material and Weight: Tubes with 2 or 2.5 mm wall thickness (14–19 kg for a 6-m length) directly affect price. Heavier tubes mean greater strength and higher price.

- Material Quality: Use of high-quality steel like ST37 ensures scaffold longevity and resistance.

- Welding Standard: Quality CO₂ welding enhances scaffold stability.

- Protective Coat: Furnace-baked paint or galvanization increases rust resistance and extends life.

- Market Fluctuations: Steel prices and transportation costs directly affect scaffold prices.

Choosing low-quality materials may reduce scaffold prices, but raises the risk of failure and associated costs. Always consult experts and choose trusted sources for quality and fair pricing.

Table of Price-Affecting Factors in Scaffold Purchase

| Factor | Description | Impact on Price |

| Material Quality | Steel grade (e.g. ST37) | Higher quality, higher price |

| Thickness & Weight | Common thickness: 2 or 2.5 mm | Heavier, more expensive |

| Protective Coating | Oven paint or hot-dip galvanized | Higher initial cost, longer lifespan |

| Manufacturing Standard | Engineered welding and precision | Higher production cost, guaranteed quality |

| Market Fluctuations | Steel price & transport rates | Affects the daily pricing |

| Manufacturer Brand | Reputation and credibility | Renowned brands cost more |

Beyond Scaffolding: The Complete Construction Equipment Ecosystem

A scaffold system alone cannot accommodate all needs of a construction project. Project success relies on an integrated ecosystem of complementary equipment. Zemanco provides a comprehensive range of construction tools, offering safe and efficient solutions for purchasing scaffold and its accessories.

The Vital Role of Construction Jacks

Ceiling and support jacks are crucial for stabilizing formwork and vertical structures. Here are the main types and their applications:

Simple Ceiling Jack: This economic jack is suitable for supporting light slab formworks in confined spaces. Purchasing a simple ceiling jack is cost-effective for small projects.

U-Head Jack: This jack is fitted on top of ceiling jacks or scaffolds to safely secure horizontal beams (such as timber or soldiers). For price and purchase details on U-head jacks, consult Zemanco.

Support & Plumb Jacks: These jacks are designed to align and withstand lateral loads during wall and column concreting. Purchasing a plumb jack ensures quality and vertical precision for structures.

Modern & Intelligent Concrete Formwork Systems

Modular formwork speeds up and enhances quality in concrete projects. Zemanco offers:

- Modular Metal Formwork: Highly durable, reusable, and favored for construction sites.

- Column Formwork: Designed for square, rectangular, and round sections. Round types are split into two semicircles for easy assembly.

- Wall Formwork: Available in single-sided and double-sided options for wall construction, including special formwork for architectural exposed concrete (smooth, flawless surfaces).

For seamless, modern facades, using exposed concrete formwork is one of the most popular and efficient choices.

Zemanco Innovative Formwork

- ZEMAX Variable Column Form: Enables multiple square/rectangular column sizes with a single kit.

- ECO Roof Form: Economic, robust alternative to polystyrene for concrete roofs.

- Tunnel Form: For tunnel and culvert lining—both hydraulic and mechanical models.

- Precast Concrete Form: For fast, high-volume casting in factories.

Formwork Accessories: Clamps, pins and wedges, and tie rods for secure, robust connections.

For price inquiries or formwork equipment purchase, contact Zemanco.

Wooden Formwork Essentials

Wooden tools are vital for concrete surface quality and site safety:

Plywood: Plywood panels with waterproof glue provide a very smooth finish for exposed concrete.

H20 Timber Beam: With an I-shaped profile, it provides high strength with less weight than traditional lumber. Buying H20 timber beams boosts installation speed.

Footboard Plank: Made of premium Russian wood with metal clamps for safe work at height. Contact Zemanco for quality footboards.

Ensuring Scaffold Performance

A scaffold is a safety system for work at height; standards must be followed.

Assembly and Installation Principles

- Sub-base Preparation: Scaffold base must be solid and level. For loose soil, footboard planks are mandatory.

- Bracing: Scaffold must be braced to the main structure to resist wind and lateral forces.

- Standard Spacing: Leg intervals and at least one meter clearance from power lines (under 300 volts) are required.

Maintenance and Lifespan Extension

- Daily Inspection: All parts and connections must be checked before each shift.

- Cleaning and Oiling: Tubes must be kept clean and moving parts oiled.

- Storage: Store in a dry, sheltered place to prevent rust.

Conclusion: Smart Choice for Scaffold Purchase

Scaffold purchase is a technical and economic decision that must be done with care. Modern scaffolds (triangular, hammer, H-frame) are effective and safer alternatives to traditional scaffolds. The price depends on material, weight, coating, and market fluctuations. For long-term projects, buying is more cost-effective than renting, but safety must not be sacrificed for cost. Purchasing used scaffold is not recommended due to safety risks.

Zemanco, with products such as ZEMAX variable column formwork, ECO slab form, and jacks, offers a complete ecosystem for your construction projects. For price inquiries and scaffold purchases, contact Zemanco’s experts.

Frequently Asked Questions about Scaffold Price and Purchase

Here are the most common questions about scaffold pricing and purchase. Stay with us for details.

What is scaffold and how does it differ from traditional scaffolding?

A scaffold is a modern, modular system built with standardized, pre-fabricated parts and connections for faster, safer installation compared to traditional scaffolding.

How much does scaffold rental cost?

Rental costs depend on several factors