Comprehensive Guide to Concrete Efflorescence

Concrete efflorescence, also known as “efflorescence,” is a common phenomenon in the construction industry that is primarily recognized as an aesthetic issue. This phenomenon refers to the appearance of white, gray, or even colored salt deposits on concrete surfaces and is caused by the movement of water within the concrete. However, the significance of this phenomenon extends beyond its visual aspect; efflorescence can be an indicator of deeper problems related to moisture management, concrete mix design, and improper concrete curing methods.

In this context, precise and high-quality execution of concrete formwork systems plays a key role in reducing cracks, porosity, and surface irregularities, all of which can become pathways for water infiltration into the concrete. For example, the use of modular metal formwork or modular formwork systems in constructing walls and columns not only increases the dimensional accuracy of the structure but also creates a smoother and more uniform concrete surface, conditions that prevent moisture penetration.

Furthermore, in projects requiring construction of one-sided or two-sided concrete walls, appropriate support systems such as wall and column support jacks or triangular shoring can prevent mortar leakage and the formation of capillary pathways.

Even in constructing arched wall formwork or precast concrete formwork, precise control of fresh concrete pressure through appropriate formwork systems prevents the formation of early cracks.

Precast Concrete Parts Formwork

Regarding columns, the use of round column formwork or ZEMAX variable column formwork achieves a clean, leak-free appearance while preventing the formation of capillary pores that could transfer water to the surface in the future. All these issues collectively demonstrate that formwork quality is the first line of defense against moisture and efflorescence.

ZEMAX Variable Column Formwork

For safe and precise execution of these systems, the presence of appropriate scaffolding is essential. At heights, the use of triangular scaffolding or omega triangular scaffolding provides worker safety and precise access to formwork points.

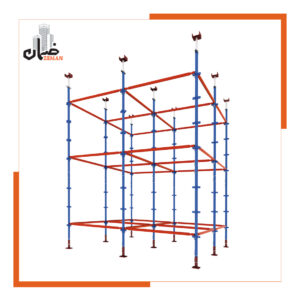

In industrial and construction projects, cup lock scaffolding (cup lock scaffolding) is an ideal option for supporting roof and wall formwork operations due to its modularity and assembly speed. Additionally, in cases requiring flexible and lightweight scaffolding, service scaffolding or H-frame scaffolding can provide the necessary efficiency.

For supporting concrete slabs, simple slab jacks or U-head jacks along with ECO slab formwork maintain structural integrity during concrete pouring. To ensure vertical accuracy of H-frame scaffolding columns and walls, purchasing plumb jacks is also an essential execution measure.

At foundation levels, foundation formwork using footboards and formwork plywood provides initial stability and waterproofing. At the same time, proper pricing of these equipment, such as footboard price, wall back support jack price, can be effective in precise project budget planning and ensuring the use of quality equipment.

Finally, traditional systems still maintain their place; but even in traditional scaffolding or hammer scaffolding, attention to execution details and the use of quality formwork connections can make a significant difference in reducing moisture penetration risk. For large-scale projects, purchasing slab jacks and support jacks and purchasing U-head jacks should be done with careful examination of price and quality, as these equipment directly affect concrete surface uniformity and, consequently, its resistance to efflorescence.

Types of Concrete Efflorescence and Methods for Identifying the Root Cause

Understanding the distinction between different types of efflorescence is a critical step toward adopting the correct and effective solution. In general, concrete efflorescence is categorized into two main types:

- Primary Efflorescence

- Secondary Efflorescence

This distinction relates not only to the time of occurrence but also to the inherent nature of the underlying problem. Primary efflorescence is typically a temporary and aesthetic issue that appears shortly after concrete construction and gradually disappears without causing structural damage. This type of efflorescence mainly results from excess mix water that moves to the surface during the cement hydration process.

That water carries alkaline salts and calcium hydroxide to the surface, where they form white deposits after evaporation. This phenomenon usually appears between one month and one year after the concrete is cast. The most important characteristic of primary efflorescence is that the near‑surface sources of salt are gradually depleted and consumed; therefore, this type of efflorescence usually fades naturally within two to three years without any intervention.

In some cases, rainfall can naturally wash away the remaining deposits. Consequently, preventive measures for primary efflorescence should focus on optimizing the concrete mix and proper curing to avoid excess water and the formation of a porous structure.

In contrast, secondary efflorescence is a persistent and ongoing problem that indicates a continuous source of moisture. This type of efflorescence may appear months or even years after concrete construction. In such situations, water from external sources—such as rain, melting snow, groundwater, roof leakage, or inadequate drainage—penetrates into the concrete structure.

The infiltrated water carries the existing alkaline salts within the concrete up to the surface, where evaporation leaves efflorescent deposits. While primary efflorescence draws upon limited near‑surface salts, secondary efflorescence is sustained by endless external moisture sources; hence, unless the source of moisture is eliminated, efflorescence will continuously reappear.

This type of efflorescence can also signify more serious problems such as steel reinforcement corrosion, degradation of building materials, or improper construction practices. Therefore, accurate identification between these two types is critical for determining the appropriate remedy. If efflorescence stems from a temporary issue, surface cleaning may suffice; however, if it results from a permanent moisture problem, actions such as sealing, drainage correction, or leak repair are essential.

Diagnosing the root cause of efflorescence is the first and most important step in addressing it. Before taking any action, the following fundamental question must be asked:

Is this efflorescence caused by a temporary issue or by a permanent one that requires root‑level correction?

To answer this, consider the following factors:

- First — time of occurrence: Primary efflorescence typically appears within the first few months after construction, especially during rainy or cold seasons. If efflorescence persists year‑round, particularly in dry summer conditions, it most likely indicates a permanent moisture problem.

- Second — intensity and recurrence: If efflorescence occurs once temporarily and then completely disappears, it is likely primary. However, if it reappears repeatedly in the same area even after cleaning, that is a strong indicator of a continuous moisture source.

- Third — environmental conditions around the structure: Carefully inspect site drainage, container strips, airflow systems, and the roof. Does rainwater drain properly from the roof and sealant strips? Is the ground around foundations sloped toward the building, causing water to collect? Improper drainage may result in water accumulation around foundations and increased surface moisture in the concrete.

- Fourth — presence of leaks: Are there visible damp spots or cracks in concrete walls, ceilings, or parking decks? Leakage from these areas can be the primary moisture source for secondary efflorescence. To ensure there are no leaks, check air circulation systems and container strips, and, if necessary, consult a professional to evaluate structural integrity. Ultimately, if efflorescence continues under dry conditions, subsurface moisture rising through capillary action is suspected. This can be resolved by installing or repairing a vapor barrier beneath the concrete. Therefore, root‑cause diagnosis is a deductive process that requires careful inspection of construction and environmental conditions. Once the moisture source is precisely identified, corrective and sustainable solutions can be applied.

| Characteristic | Primary Efflorescence | Secondary Efflorescence |

| Time of Occurrence | Typically 1 month to 1 year after concrete construction, especially in rainy seasons. | May appear months or even years after construction. |

| Moisture Source | Excess mix water not required for cement hydration. | External water (rain, groundwater, leakage). |

| Salt Source | Alkaline salts within concrete materials (cement, sand, aggregates). | Salts introduced from external sources into the concrete. |

| Recurrence | Fades naturally within 2–3 years and usually occurs once. | Continuously reappears unless the moisture source is removed. |

| Nature of the Problem | Primarily aesthetic and temporary. | Indicates persistent moisture problems and may lead to structural issues. |

| Solution | Optimize concrete mix and curing for future prevention. | Precisely identify and eliminate moisture source (drainage, waterproofing, leak repair). |

With this understanding, a rational plan can be developed to combat efflorescence. If the problem is temporary, the focus should be on prevention. If permanent, root‑cause measures are required. This approach not only yields the best outcome for clients but also enhances Zeman’s position as a problem‑solving company rather than merely a product supplier. In the next section, we discuss preventive measures considered the best and most economical way to address efflorescence.

The Best Way to Prevent Concrete Efflorescence

The saying “prevention is better than cure” holds true in construction as well, and is absolutely valid for concrete efflorescence. The best and most effective method of control is prevention during the design and construction phases. This not only drastically reduces future maintenance and repair costs but also significantly enhances the durability and strength of structures. Preventive strategies focus on several key aspects:

1. Optimizing the Concrete Mix

The first and most critical stage in preventing efflorescence is designing a proper concrete mix. The water‑to‑cement ratio (w/c ratio) is a key parameter; a high ratio increases porosity and permeability, allowing water and salts to migrate more easily to the surface.

Solutions:

- Lower the water‑to‑cement ratio for a denser and more durable structure.

- Use washed, salt‑free aggregates and sand.

- Use soft or high‑quality mineral water for mixing concrete.

- Select low‑alkali cement to reduce calcium hydroxide formation.

Pozzolanic materials, such as Class F fly ash or microsilica, react with calcium hydroxide to densify concrete and help prevent efflorescence.

2. Using Internal Admixtures

These admixtures are added during mixing and uniformly distributed throughout the concrete.

Main types of admixtures:

- Water‑repellent admixtures: such as polymeric waterproofers or Haiflex Moisture Insulator, which create hydrophobic layers within pores to prevent moisture penetration.

- These materials also protect concrete against rebar corrosion and damage caused by freeze–thaw cycles.

Anti‑Efflorescence Admixtures

- Typically contain fatty acids or nanoparticles that react with calcium hydroxide, preventing calcium carbonate formation.

- An example is the Nano Anti‑Efflorescence Agent (Nanosil), which creates insoluble compounds within concrete to block salt migration to the surface.

Plasticizing Admixtures

By increasing concrete workability, they reduce water demand, thereby minimizing porosity and improving durability.

3. Proper Concrete Curing

Curing means maintaining adequate moisture and temperature during the early stages of cement hydration. Rapid water evaporation (particularly in hot or dry weather) can cause incomplete hydration and porous, weak concrete—a suitable environment for efflorescence.

Effective curing methods include:

- Covering concrete surfaces with plastic sheets or wet burlap.

- Keeping the surface moist through fogging or water spray.

- Using evaporation retarders that form thin surface films to prevent moisture loss.

Proper curing not only prevents efflorescence but also increases compressive strength and overall durability.

4. Proper Moisture Management During Construction

Even the best concrete may develop efflorescence when continuously exposed to moisture; hence, prevent water penetration and accumulation around the structure.

Key actions:

- Design and implement an efficient drainage system around the building.

- Provide proper ground slope away from foundations to direct rainwater outward.

- Install vapor barriers beneath the concrete to block moisture migration from soil.

- Seal joints and cracks with specialized waterproof tapes or sealants.

Additionally, use proper container strips and seal joints and cracks during construction to prevent water infiltration through walls. These measures comprehensively prevent water ingress and thus eliminate the conditions needed for efflorescence formation. Combining these preventive strategies ensures long‑term protection and preserves the durability and aesthetic quality of concrete structures throughout their service life.

| Preventive Measure | Description and Benefits |

| Optimizing Concrete Mix | Reducing water‑cement ratio, using high‑quality raw materials and pozzolans for dense, low‑permeability concrete. |

| Using Water‑repellent Admixtures | Admixtures like polymeric waterproofers that seal concrete pores and eliminate water penetration. |

| Using Anti‑Efflorescence Additives | Additives that react with calcium hydroxide to prevent calcium carbonate formation. |

| Proper Curing | Methods such as plastic covering or evaporation‑retarding admixtures to prevent rapid drying and ensure full hydration. |

| Environmental Moisture Management | Adequate drainage, vapor barriers under concrete, and sealing joints to prevent external water intrusion. |

These preventive measures demonstrate that concrete efflorescence is a manageable issue — with proper attention to design and construction details, it can be entirely avoided. This proactive approach is the best investment for project owners and architects alike.

Removing Efflorescence from Existing Concrete Structures

Although prevention is better than correction, efflorescence occasionally appears on existing buildings. In such cases, a logical step‑by‑step approach must be followed to resolve it. This methodology comprises three main stages:

Identifying and Eliminating the Moisture Source

The first and most crucial step is accurately locating and eliminating the moisture source. Prior to any treatment, ensure that the source responsible for secondary efflorescence has been remedied. If this step is neglected, any cleaning will be temporary and efflorescence will continuously reappear. This may involve correcting site drainage, repairing leaks in roofs or walls, improving ventilation in damp areas such as gardens, or installing/replacing container sealing strips.

If caused by groundwater, an underpinning drainage system or reinstallation of the vapor barrier beneath the concrete may be required. This step is of vital importance; without eliminating the moisture source, all subsequent efforts will be ineffective.

Ensure that no paths remain for water infiltration from soil into concrete, as moisture is the primary factor that triggers efflorescence.

Surface Cleaning

The second stage is cleaning the concrete surface. After confirming the moisture source has been removed, efflorescent deposits must be lifted from the surface. Cleaning methods depend greatly on deposit type. For soft, water‑soluble surface deposits, mechanical cleaning is effective — such as low‑pressure washing, scrubbing with soft (non‑metallic) brushes, or even gentle wire‑brushing. These methods work well for primary or light deposits that are still soluble. For hard, insoluble crystalline deposits like calcium carbonate formed by reaction with carbon dioxide, mechanical methods may be ineffective.

In those cases, chemical methods are required. These include mild acids such as vinegar (acetic acid) or diluted hydrochloric (muriatic) acid solutions. Acids react with calcium carbonate, converting it into soluble compounds that can be rinsed away. For example, applying a 1:20 dilution of hydrochloric acid for 10–15 minutes, followed by complete rinsing with water, is effective. Extreme caution is necessary, however — acids can alter surface color and texture, especially on colored or waterproofed concrete surfaces.

Therefore, testing acid application on a small inconspicuous area is essential before full use. Acids may also react with embedded reinforcement, causing corrosion, so direct contact must be avoided. The safest approach is to use commercial efflorescence removers, typically based on mild acids such as citric acid. Application steps involve distributing the solution, allowing 5–10 minutes for reaction, and rinsing thoroughly. Every chemical treatment must conclude with full rinsing to avoid residual acid that could cause long‑term damage.

Surface Sealing and Protection

The third and final stage involves sealing and protecting the surface after cleaning — a crucial step to prevent recurrence. Following cleaning, the concrete may remain porous and ready to absorb moisture and salts. Applying a protective coating resolves this issue. These coatings fall into two main categories: Penetrating Sealers and Topical Coatings. Penetrating sealers are hydrophobic liquids that seep deep into concrete pores, reacting chemically to form compounds that block pores and protect against water infiltration.

These coatings allow internal vapor exchange (breathable), preventing issues such as spalling caused by trapped moisture. Products like Zeman’s “Concrete Penetrant” are effective solutions for protecting concrete from efflorescence, corrosion, and abrasion. Topical coatings—such as epoxy, polyurethane, or polyaspartic paints—form a physical waterproof barrier on the surface, providing excellent chemical and abrasion resistance. They are ideal for areas exposed to heavy traffic, chemicals, or harsh environmental conditions.

The selection of coating type depends on environmental conditions and specific project needs. In all cases, applying a protective layer after cleaning is essential to prevent reappearance. This comprehensive approach—including moisture source removal, thorough cleaning, and surface sealing—can effectively resolve efflorescence in existing buildings and significantly increase concrete’s lifespan and durability.

| Cleaning Method | Suitable Deposit Type | Notes and Precautions |

| Mechanical Cleaning | Soft, water‑soluble surface deposits. | Use non‑metallic brushes to avoid surface damage. |

| Water Washing | Surface and soluble deposits. | Ensure thorough rinsing to remove residual salts. |

| Chemical Acids | Hard, insoluble, carbonate deposits. | Acids can alter color and texture; always test a small area first. Prevent acid contact with steel reinforcement. |

| Commercial Products | Medium to heavy deposits. | Safer than raw acids; typically contain citric acid. |

These corrective measures, combined with preventive strategies, form a comprehensive system for managing concrete efflorescence. By thoroughly understanding the nature of the issue and adopting a step‑by‑step approach, construction projects can reliably prevent or effectively eliminate efflorescence when it occurs.

Conclusion: Concrete efflorescence—also known as “efflorescence”—results from the movement of water and soluble salts within concrete, which appear as white deposits after evaporation. Although it may seem merely an aesthetic defect, efflorescence can indicate chronic moisture or deficiencies in mix design or curing. Precise identification of type (primary or secondary), moisture source, and salt composition is the first step toward effective resolution. Preventive actions through optimized mix design, environmental moisture control, anti‑efflorescence additives, and proper curing remain the best and most durable methods for preserving the longevity and appearance of concrete structures.