Joist-and-Block Slab | Comprehensive Guide to Pricing, Advantages, Disadvantages, Types, and Execution

In the modern construction industry, selecting the appropriate type of floor system is one of the key decisions that has a direct impact on construction speed, cost, safety, and the overall performance of the structure. Among the many available options, the joist-and-block slab system has become an inseparable element in numerous residential and commercial projects in Iran due to its ease of execution, economic efficiency, and compatibility with various structural frameworks. Relying on precast joists as secondary beams and lightweight blocks as infill elements, this system is considered a reliable and efficient alternative to outdated floor systems such as jack-arch slabs, offering superior resistance to dynamic loads such as earthquakes.

The integrity and performance of this system depend on the precise interaction of four main components:

- Joists, which are responsible for transferring loads

- Infill blocks, which occupy the non-structural space

- Reinforcing bars, which ensure structural strength

- The topping concrete, which is cast in place. The widespread use of this floor system in our country is not limited solely to its apparent advantages, but rather stems from its adaptability to the most common structural systems, namely reinforced concrete and steel frames.

This compatibility enables engineers and contractors to utilize this system for a wide range of projects without requiring fundamental changes to the structural design. As a result, this flexibility has allowed the joist-and-block slab system, as a versatile solution, to capture a significant share of Iran’s construction market. In the following sections, a detailed analysis of each of these components and their modes of operation will be presented.

What Is a Joist-and-Block Slab?

The joist-and-block slab is one of the most widely used floor systems in residential, administrative, and commercial buildings in Iran. This system consists of a combination of precast joists (typically concrete or steel) and ceiling blocks (made of clay, lightweight concrete, or polystyrene), which are integrated on site with a structural topping concrete layer (cast-in-place concrete). The primary objectives of this system are to reduce the dead weight of the slab, increase construction speed, and minimize material consumption.

In this method, the joists function as the main load-bearing members, while the blocks serve solely as infill elements and provide thermal and acoustic insulation. After placing the blocks between the joists, a mesh of temperature and shrinkage reinforcement bars is installed over them, followed by concrete casting. The final result is a monolithic, durable, and relatively lightweight slab capable of spanning typical clear spans of up to 8 meters.

Reasons for the Popularity of the Joist-and-Block Slab in Iran

The use of the joist-and-block slab system is very common due to the following reasons:

- Reduced concrete consumption compared to solid slabs

- Lower dead weight of the structure

- Ability to be executed without complex equipment

- Compatibility with formwork and scaffolding systems

During the execution process of this slab system, the use of standard scaffolding and formwork systems plays a critical role in ensuring safety and final quality. For this reason, many professional contractors make use of products from Zaman Company, such as the modular formwork system and standard metal scaffolding.

Components of the Joist-and-Block Slab

Joists

Joists, acting as secondary beams within this system, form the structural backbone of the slab and are responsible for carrying both dead and live loads. These precast components are available in various types, each designed for specific conditions and requirements.

Concrete Joists

The most common type of joist in Iran is the concrete lattice joist, which consists of a steel truss (including tensile, compressive, and diagonal rebars) and a concrete bottom flange. The concrete flange is manufactured in the factory, while the reinforcing bars are assembled and connected on site. Another type is the prestressed joist, which is produced by tensioning high-strength steel strands prior to concrete casting.

This process induces a permanent compressive stress within the concrete, significantly increasing its flexural strength. Its key advantage is the complete elimination of the need for temporary ceiling props and shoring. Removing this stage directly results in substantial savings in time, labor, and costs associated with equipment such as standard adjustable props and U-head props, and is considered a major competitive advantage over other slab systems.

Steel Joists (Kromit)

Kromit joists, also known as steel joists, are manufactured from open-web steel sections. Similar to prestressed joists, these joists are self-supporting and do not require temporary shoring during execution. This characteristic allows scaffolding systems, triangular shoring, and props to be removed from beneath the slab after the concrete has gained sufficient strength, which in turn significantly accelerates the overall construction process.

Infill Blocks — From Clay to Polystyrene

Blocks are non-structural elements that fill the space between joists. Their primary function is to provide a surface for casting the topping concrete and to reduce the dead load of the slab. The selection of block type depends on factors such as cost, weight, and insulation properties.

Types of Blocks

- Clay Blocks:

Manufactured from clay, these blocks provide good thermal insulation. They are lighter than concrete blocks and are also considered cost-effective. - Concrete Blocks:

Composed of cement, sand, and water, these blocks offer high compressive strength and thermal resistance. However, due to their greater weight compared to other types, they impose a higher dead load on the structure. - Polystyrene (EPS) Blocks:

These are the lightest option and, due to their extremely low weight, significantly contribute to reducing the building’s dead load. A reduction in dead load directly decreases seismic forces, thereby enhancing the overall structural performance. However, non-standard polystyrene blocks perform poorly in fire conditions and may release toxic gases when ignited, posing serious risks to occupants. This characteristic represents a major safety challenge in construction projects and highlights the critical importance of using fire-retardant types under strict supervision.

| Feature | Concrete Block | Clay Block | Polystyrene Block |

|---|---|---|---|

| Material | Cement, sand, and water | Fired clay | Expanded polystyrene (EPS) |

| Weight | Heavy | Light | Very light |

| Compressive Strength | High | Low | Very low |

| Thermal / Acoustic Insulation | Good | Good | Very good |

| Fire Safety | Fire-resistant | Fire-resistant | Risk of toxic gas emission |

| Primary Application | Infill | Infill | Infill and dead-load reduction |

| Initial Cost | Moderate | Low | Moderate |

Topping Concrete and Reinforcement — A Critical Role in Structural Strength

After placing the joists and blocks, the topping concrete (cast-in-place slab) is poured over them with a minimum thickness of 5 centimeters. This concrete layer bonds the joists and reinforcing bars together, creating an integrated and composite structural system.

Reinforcement Bars

At this stage, two key types of reinforcement bars are used:

Temperature Reinforcement Bars

These rebars are placed in a mesh pattern, perpendicular to each other, over the concrete and blocks. Their primary function is to resist stresses caused by thermal expansion and contraction of the concrete and to prevent cracking.

Edka (Ootka) Reinforcement Bar

This reinforcement bar, designed in the shape of a duck’s neck, is installed at the connection point between the joist and the main beam. The purpose of installing the Edka bar is to increase shear resistance at this critical location and to prevent dislodgement or displacement of the joist from its support. This bar effectively strengthens the joist bearing zone and ensures its composite and integrated performance with the main beam. The use of Edka reinforcement is directly associated with addressing one of the key technical weaknesses of the joist-and-block slab system, namely the connection between precast components and the cast-in-place structural elements.

Types of Joist-and-Block Slabs and Comparison with Alternatives

In the modern construction industry, the joist-and-block slab is not the only available option. Comparing it with competing systems provides a more comprehensive perspective for informed decision-making. Each system, with its own advantages and limitations, is optimized for specific applications.

Joist-and-Block Slab vs. Solid Concrete Slab

Solid Concrete Slab:

Constructed monolithically from concrete and reinforcement, this system is very heavy and imposes significant loads on the structure and foundation. However, due to its high rigidity, it offers excellent resistance to earthquakes, fire, and sound transmission, and is suitable for large spans.

Joist-and-Block Slab:

In comparison, it has a much lower weight and is an ideal option for reducing the building’s dead load. Its execution is simpler and faster, but it does not possess sufficient rigidity for very large spans.

Joist-and-Block Slab vs. Waffle Slab

Waffle Slab:

This is a modern system that reduces slab weight by eliminating unnecessary concrete in the tension zone and enables the coverage of very large spans (up to 15 meters). Because waffle slabs do not require polystyrene infill blocks, they completely eliminate fire hazards and provide better acoustic insulation.

Analytical Note:

The waffle slab has been developed as a solution to the challenges of long spans and the safety risks associated with joist-and-block slabs. This system allows builders, particularly in larger and more modern projects, to use an optimized and safe structural solution instead of employing double joists or other alternative methods.

Joist-and-Block Slab vs. Composite Slab

Composite Slab:

This system is specifically designed for steel structures and, due to the composite action between steel and concrete, offers very high execution speed. One of its main advantages is the elimination of the need for shoring beneath the slab and the ability to cast concrete on multiple floors simultaneously.

Analytical Note:

The choice of a composite slab is highly dependent on the type of structural frame. In contrast, the joist-and-block slab offers greater flexibility, as it can be used in both steel and reinforced concrete frames. This adaptability has made it a more widely used option across diverse construction projects.

| Feature | Joist-and-Block | Solid Concrete Slab | Waffle Slab | Composite Slab |

|---|---|---|---|---|

| Execution Speed | High | Low | High | Very High |

| Cost | Economical | High | High | High |

| Maximum Span | 7–8 m | 10 m and above | Up to 18 m | 7–8 m |

| Slab Weight | Light | Heavy | Light | Very Light |

| Rigidity | Moderate | Very High | High | High |

| Fire Resistance | Moderate to Poor | High | High | High |

| Need for Shoring | Yes (except Kromit joists) | Yes | No (except one-way waffle) | No |

| Architectural Appearance | Requires finishing | Requires finishing | Exposed and aesthetic | Requires finishing |

| Structural Frame Type | Concrete and Steel | Concrete | Concrete and Steel | Steel |

Step-by-Step Guide to Executing a Joist-and-Block Slab

The correct execution of a joist-and-block slab plays a critical role in structural safety, the service life of the building, and the prevention of cracking and excessive deflection. This process must be carried out strictly in accordance with structural drawings and technical codes, and the use of standard, certified equipment at every stage is essential.

Stage One: Preparation and Substructure Setup

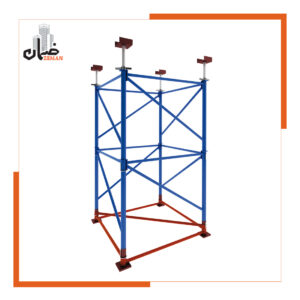

The first and most critical stage in the execution of a joist-and-block slab is proper substructure preparation and shoring. This stage involves installing support props beneath the joists and formwork to prevent sagging or deflection of the slab during concrete casting. The standard spacing of props depends on the type of joist used: approximately 120 centimeters for precast joists and about 3 meters for prestressed joists. For slabs with a clear height exceeding 3.5 meters, the use of scaffolding systems or H-frame shoring is mandatory due to their significantly higher load-bearing capacity.

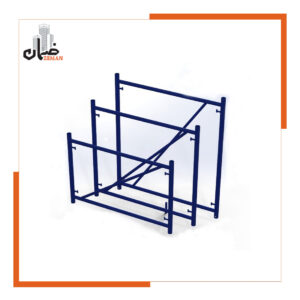

Stage Two: Formwork Installation and Joist Layout

Formwork is installed around the slab perimeter and beneath the joists. These forms may consist of modular metal formwork systems or plywood panels combined with timber beams. Using H20 timber beams as horizontal supports reduces the number of required props and facilitates faster and more efficient execution. After formwork installation, the joists are placed on the main supports at specified spacing (typically around 50 centimeters). In steel frames, joists are secured by welding, while in reinforced concrete frames they are anchored using starter rebars. At this stage, ECO ceiling formwork can also be used as an economical alternative solution.

By offering a comprehensive range of concrete formwork systems and modular formwork solutions—including ZEMAX variable column formwork, tunnel formwork, precast concrete element molds, and a full set of formwork accessories—Zaman Company enables engineers to ensure integrity, safety, and consistency throughout all construction stages.

ZEMAX Variable Column Formwork

From façade wall formwork and single-sided wall formwork to curved wall formwork, double-sided wall formwork, and all types of circular, rectangular, and square column formwork, every project requirement—from foundation to roof—is covered with the highest level of quality. In addition, to stabilize vertical formwork on site, the use of alignment props or wall-and-column support props is essential to prevent any deviation or displacement of the forms during concrete pouring.

Step-by-Step Guide to Executing a Joist-and-Block Slab

Proper execution of a joist-and-block slab plays a vital role in structural safety, the service life of the building, and the prevention of cracking and excessive slab deflection. This process must be carried out in full compliance with structural drawings and technical standards, and the use of standard equipment at every stage is essential.

Stage Three: Placement of Infill Blocks and Reinforcement

After the joists are installed, the infill blocks are placed between them. These blocks do not carry structural loads; instead, they act as permanent formwork for the topping concrete. At this stage, temporary walking planks are installed to ensure safe movement of workers across the slab. Subsequently, temperature reinforcement bars and Edka (Ootka) rebars are installed at their designated locations.

Stage Four: Concrete Casting and Curing

This stage represents the core of the slab construction process. Prior to concreting, the slab surface must be thoroughly cleaned and free from dust, debris, or contaminants. Especially in hot weather conditions, pre-wetting the slab surface is essential to prevent the joists and blocks from absorbing water from the fresh concrete. The concrete should be prepared with the specified strength class (typically C25) and poured uniformly and continuously to avoid the formation of cold joints. The use of mechanical vibration is critical to expel entrapped air and prevent honeycombing of the concrete.

Stage Five: Formwork Removal and Prop Stripping

After concreting, sufficient time must be allowed for the concrete to set and achieve its initial strength. The duration for keeping props and formwork in place typically ranges from 7 to 14 days, depending on ambient temperature, concrete type, and weather conditions. Removal of the props must be carried out gradually and without sudden impacts to avoid damage to the slab. Problems such as excessive sagging or cracking often originate from improper execution at this stage—particularly when prop spacing is not respected or non-standard materials are used. This highlights that the apparent simplicity of the joist-and-block slab system should not lead to negligence in execution, and strict engineering supervision is essential throughout all stages.

Advantages and Disadvantages of Joist-and-Block Slabs: A Comprehensive Analysis

Advantages

Due to several key benefits, the joist-and-block slab remains one of the most popular flooring systems in the construction industry:

- Speed and ease of execution:

The use of precast joists significantly accelerates installation compared to traditional slab systems. - Economic cost:

The use of relatively inexpensive materials such as concrete and clay blocks, along with reduced consumption of concrete and reinforcement compared to solid slabs, lowers overall project costs. - Lightweight system and reduced dead load:

Especially when polystyrene blocks are used, the slab weight is substantially reduced, which in turn lowers the building’s dead load and seismic forces acting on the structure. - Thermal and acoustic insulation:

Infill blocks—particularly polystyrene and clay types—provide effective thermal and sound insulation, contributing to energy efficiency and improved occupant comfort.

Disadvantages

Despite its many advantages, the joist-and-block slab system also presents certain challenges that must be carefully considered prior to selection:

- Lower rigidity:

Compared to solid concrete slabs, this system exhibits lower stiffness, which may result in noticeable vibrations or deflections under dynamic loads. - Limitations in span and geometry:

Execution becomes difficult for large spans (greater than 7–8 meters) or for complex geometries such as curved or triangular layouts. For projects requiring longer spans, alternative systems such as waffle slabs or composite slabs are generally recommended. - Safety concerns:

There is a risk of damage to the joist bearing zone during transportation or improper installation. In addition, non-standard polystyrene blocks can release toxic gases during a fire, posing a serious safety hazard. - Dependence on auxiliary equipment:

Safe and optimal execution requires the use of traditional scaffolding systems and heavy-duty shoring solutions, such as H-frame scaffolding, cuplock scaffolding, ringlock systems, and service scaffolding for work at height.

Factors Affecting the Cost per Square Meter of a Joist-and-Block Slab

The cost of a joist-and-block slab is not a fixed value and depends on a combination of technical, execution-related, and economic factors. Understanding these factors enables project owners to estimate the final project cost more accurately and to avoid unforeseen cost overruns.

Type of Joists Used

One of the most decisive factors affecting the price is the type of joist. Joists are generally divided into two main categories:

Ordinary Reinforced Concrete Joists

- More affordable price

- Widely used in residential buildings

- Lower cost per square meter of slab

Prestressed Joists

- Higher strength and durability

- Suitable for longer spans

- More expensive compared to conventional concrete joists

Using standard and high-quality joists—manufactured according to technical regulations—has a direct impact on the safety and longevity of the slab.

Type and Material of Ceiling Blocks

Although ceiling blocks are nonstructural elements, they play an essential role in the overall weight and final cost of the slab.

Clay Blocks

- Reasonable price

- Good thermal insulation

- Higher fragility during installation

Cement or Lightweight Concrete Blocks

- Higher mechanical strength

- Heavier weight

- Variable price depending on aggregate composition

Polystyrene (EPS) Blocks

- Very lightweight

- Excellent thermal and acoustic insulation

- Higher price compared to traditional blocks

The choice of block type can significantly affect the cost per square meter of the joist-and-block slab.

Concrete Consumption and Strength Grade

Concrete casting constitutes a major part of the cost of a joist-and-block slab. The primary influencing factors include:

- Thickness of the topping concrete layer

- Concrete grade (for example, C20 or C25)

- Transportation and pumping costs

The greater the concrete thickness or required strength, the higher the final cost will be.

Quantity of Reinforcement Used

The reinforcement bars used in joist-and-block slabs consist of:

- Joist reinforcement bars

- Temperature reinforcement

- Additional reinforcement around openings

Fluctuations in steel prices directly affect the overall cost of the slab. Therefore, the timing of rebar purchase is an important consideration.

Formwork and Shoring Costs

One of the important yet often overlooked expenses is the formwork and shoring of the slab. Using standard equipment such as:

- Simple Ceiling Jack

- Metal scaffolding

- Steel concrete formwork

If high-quality reusable products (such as those supplied by Zeman) are employed, they can reduce total construction costs in multi‑story projects.

How to Calculate the Cost of a Joist-and-Block Slab

Calculation per Square Meter

The most common method is to calculate the cost of the joist‑and‑block slab per square meter. This price usually includes:

- Joist cost

- Block cost

- Concrete cost

- Temperature reinforcement

- Execution labor cost

Approximate Example of Cost Calculation

For a typical residential building:

- Joists and blocks: X tomans

- Concrete and rebar: Y tomans

- Labor cost: Z tomans

The total of these items determines the price per square meter of the joist‑and‑block slab.

Note: Prices vary depending on the city, project conditions, and time of execution.

Labor Cost for Executing a Joist-and-Block Slab

Labor cost is one of the key components in estimating the final construction budget, and it can lead to significant differences in the cost per square meter depending on project conditions. Contrary to common misconception, labor cost is not fixed—it varies according to multiple factors.

Factors Affecting Labor Cost

Project Area and Dimensions

Generally, as the slab area increases, the labor cost per square meter decreases. For small‑scale projects (such as single‑unit buildings), the cost is often calculated as a lump sum or at a higher rate, whereas in large‑scale developments, the per‑meter rate becomes more economical.

Building Height and Number of Floors

In multi‑story buildings—especially upper floors—transporting materials and executing the slab become more challenging, leading to a higher labor rate compared to single‑ or two‑story structures.

Type of Formwork and Scaffolding System

The choice of equipment directly affects the speed of execution and manpower requirements.

Traditional Scaffolding and Shoring

- Lower execution speed

- Greater manpower required

- Higher probability of human error

Steel Scaffolding and Standard Ceiling Jacks

- Faster execution

- Reduced manpower

- Improved site safety

The use of metal scaffolding, ceiling jacks, and Zeman steel concrete formwork systems in many projects has helped reduce overall labor cost, as the execution time is significantly shortened.

Complexity of Drawings and Execution Details

Features such as:

- Irregular spans

- Cantilevered sections

- Large openings (stairways, elevators, skylights)

Increase the required time and precision, thereby raising the execution cost. In contrast, simple and repetitive slabs are less costly to construct.

Geographical Location of the Project

Labor costs differ among cities. Typically, in major urban centers, due to:

- Higher labor expenses

- More complex working conditions

The rates are higher than in smaller towns.

Methods of Calculating Labor Cost for Joist-and-Block Slab Execution

Calculation per Square Meter

The most common approach is to calculate labor cost per executed square meter of slab. This normally includes:

- Placement of joists and blocks

- Installation of temperature reinforcement

- Concrete pouring

Formwork, scaffolding, and shoring costs are usually calculated separately unless explicitly included in the contract.

Lump Sum (Contractual) Calculation

In some projects, the entire slab execution is assigned to a construction crew on a lump‑sum contractual basis. This method simplifies management for the client, but detailed work specifications must be clearly outlined in the contract.

Final Summary of Joist-and-Block Slab System

The joist‑and‑block slab is one of the most economical and widely used ceiling systems in Iran. When properly designed and executed, it provides satisfactory structural performance. Its main advantage lies in achieving a balanced combination of cost, execution speed, and safety.

To achieve optimal results during execution, it is essential to observe the following principles:

- Use of standard joists and blocks

- Accurate formwork and shoring installation

- Employing safe, high‑quality equipment

- Choosing experienced construction crews

The advantages of this system—especially in reducing structural weight and enhancing seismic performance—make it an attractive choice for residential projects. Nevertheless, as discussed, the system’s efficiency and safety depend heavily on material quality and execution accuracy. The use of wall support jacks and alignment jacks for proper formwork setup, as well as continuous supervision by the responsible engineer, are key factors ensuring structural stability and durability.

Ultimately, the success of any project depends not only on selecting the appropriate structural system but also on using quality equipment and ensuring precision at every stage. Zeman Company, by providing a complete range of plywood panels, wooden beams, and modular formwork systems, assists contractors in achieving optimal and cost‑effective results.

Frequently Asked Questions (FAQ)

Is the Joist-and-Block Slab Suitable for Earthquake-Resistant Buildings?

Yes. Due to its lighter weight, this slab exerts a smaller dead load on the structure, thereby reducing seismic forces. However, its lower rigidity under lateral loads may lead to minor vibrations, which can be effectively controlled by proper execution and compliance with technical codes.

What Are the Main Components of a Joist-and-Block Slab?

The primary elements include precast joists (concrete or steel), filler blocks (clay, cement, or polystyrene), reinforcing bars (temperature and Edka reinforcement), intermediate tie beams, and the topping concrete layer.

Can Joist-and-Block Slabs Be Used in Steel Structures?

Yes. This slab type is also applicable to steel frameworks, where joists are connected to steel beams either by welding or using Edka reinforcement bars.

Why Do Joist-and-Block Slabs Sag or Crack?

Deflection or cracking usually results from poor adherence to technical standards during execution. The main causes include improper shoring, use of nonstandard joists or concrete, and insufficient calculation of applied loads.