Comprehensive Guide to Purchasing Metal Corner Formwork – Critical Connections for Structural Integrity

In the world of modern construction and concrete projects, precision and quality are of paramount importance. When it comes to formwork for shear walls, columns, and foundations, most contractors focus primarily on the main metal formwork panels. However, there is a critical and indispensable component without which connecting formwork at corners would be impossible and the structural stability would be at serious risk: the corner formwork.

If you are planning to purchase metal corner formwork, you should be aware that these small yet powerful components play a strategic connecting role within modular formwork systems. Zeman Company, as one of the leading manufacturers of formwork equipment, aims in this article to help you make the best possible choice for your project with a clear and technical perspective.

Comparison of Internal and External Corners

This table is an excellent tool for quickly understanding the differences.

Key Differences Between Internal and External Corners

| Feature | Internal Corner | External Corner |

| Installation Location | Inside a 90-degree angle (recess) | Outside a 90-degree angle (projection) |

| Physical Structure | Generally simpler, without heavy reinforcement | Equipped with reinforcements and thicker steel plates |

| Applied Pressure | Lower pressure (concrete compression directed inward) | Very high pressure (tendency of the formwork to open) |

| Supplementary Connections | Usually pin and wedge only | Pin and wedge plus bolt and nut or soldier beam |

What Is Metal Corner Formwork and Why Is It Important?

In concrete formwork systems, when two formwork panels meet at an angle (typically 90 degrees), relying solely on pin and wedge connections is not sufficient to ensure continuity and prevent concrete slurry leakage. At these critical junctions of walls or columns, a dedicated component is required to properly cover the angle and restrain the hydrostatic pressure of concrete at the corners.

Purchasing metal corner formwork enables you to:

- Achieve rigid and secure connections: Integrate two perpendicular formwork panels into a single, unified assembly.

- Create precise angles: Construct columns and walls with accurate, square 90-degree corners.

- Prevent deformation: Avoid twisting or warping of formwork panels at corner areas under concrete pouring pressure.

In practice, the surface quality of concrete at the corners of columns and walls is directly dependent on the quality of the corner formwork used. Utilizing low-quality or non-standard corner components can lead to concrete honeycombing at the corners or even formwork failure during concrete placement. To view the main formwork panels to which these corner elements are connected, you can visit the Metal Concrete Formwork page on the Zeman Company website.

Technical Specifications and Dimensions

This table can be placed in the section titled “Types of Metal Corner Formwork” or after the explanation of “Difference Between 5 cm and 6 cm Edge Profiles,” allowing customers to quickly review standard sizes at a glance.

Zeman Standard Metal Corner Formwork Size Table

| Corner Type | Standard Heights (cm) | Cross-Section Dimensions (cm) | Main Application |

| Internal Corner | 100 / 150 / 200 | (10 × 10) | Connection of two formwork panels at internal wall and column corners |

| External Corner | 100 / 150 / 200 | (10 × 10) | Slim columns or confined spaces |

| External Corner | 100 / 150 / 200 | (10 × 10) | Rectangular columns with specific dimensions |

| External Corner | 100 / 150 / 200 | (10 × 10) | Most commonly used size for columns and shear walls |

| Zero Corner | 100 / 150 / 200 | (10 × 10) | Connection without increasing overall dimensions (Zero Angle) |

Types of Metal Corner Formwork: Which One Is Right for Your Project?

Before requesting a price quote and purchasing metal corner formwork, it is essential to understand that these components are generally classified into two main categories based on their installation position and the type of angle they create:

- Internal Corner

- External Corner

Each of these categories serves a specific purpose and cannot be used interchangeably. In the following section, we will take a closer technical look at internal corner formwork.

Internal Corner Formwork: The Architect of Inner Angles

As its name suggests, internal corner formwork is used to connect two formwork panels at the inside of an angle, such as interior room corners, wall-to-wall intersections, or the inner corners of L-shaped shear walls. This component is generally simpler in structure compared to external corners and is primarily responsible for shaping the internal concrete surface.

Standard internal corner formwork is typically manufactured with a (10 × 10) cm cross-section, meaning each flange covers 10 cm of the adjacent formwork panel. The heights of these corners correspond to the standard heights of main formwork panels (100, 150, and 200 cm). Connection to the main panels is usually achieved using pin and wedge fasteners, which are among the most widely used formwork accessories in Zeman’s product portfolio.

In the next section of this article, we will move on to a detailed technical review of external corner formwork, examine its structural differences compared to internal corners, and discuss key considerations in calculating the weight and price of these components. Stay with us.

External Corner Formwork: The Steel Armor of Columns

Unlike internal corners, which are installed inside the angle, external corner formwork is mounted on the outermost junction of two panels. If you are constructing square or rectangular columns, or forming the exterior face of shear walls, purchasing external metal corner formwork is essential.

The load applied to external corners is significantly higher than that on internal corners. This is because the hydrostatic pressure of fresh concrete tends to push the formwork outward, making corners the most vulnerable points to opening or failure. For this reason, external corner formwork is typically manufactured using thicker steel plates (usually 3 or 4 mm) and additional reinforcing elements.

Standard sizes for external corner formwork include:

- (5 × 5) and (10 × 5) corners: Suitable for columns with special dimensions.

- (10 × 10) corners: The most commonly used size for shear walls.

- Zero Corner: This special type has no projecting faces and functions solely as a connecting angle. It is used when column dimensions are exact multiples of the available formwork panel widths and no additional offset is required.

To resist the high pressure at the external corners of tall columns, pin and wedge connections are often supplemented with soldier beams or scaffolding pipes as back supports, ensuring precise vertical alignment of the column.

Golden Tip When Buying Corner Formwork: The Difference Between 5 cm and 6 cm Edge Profiles

One of the most common mistakes contractors make when purchasing metal corner formwork is ignoring the type of edge profile or flange used in their formwork system. In Iran, metal formwork systems are typically manufactured according to two main standards:

- 5 cm Edge Profile (Labe 5): The width of the bent flange is 5 centimeters.

- 6 cm Edge Profile (Labe 6): The width of the bent flange is 6 centimeters.

Why is this important?

If your main formwork panels are of the 5 cm edge type, your corner formwork must also have a 5 cm edge. Connecting a 6 cm edge corner to a 5 cm edge panel will cause misalignment of the pin and wedge holes, making proper installation impossible. Additionally, the concrete surface will suffer from uneven steps or offsets.

Zeman Company manufactures all of its corner formwork in strict compliance with precise standards to ensure full compatibility with the most common modular systems on the market. If you are unsure about the edge type of your existing formwork panels, you can send photos to our technical experts and benefit from free consultation. To complete your slab formwork system, we also recommend reviewing the range of adjustable steel props available on our website, which are essential complements to concrete construction projects.

Factors Affecting the Weight of Corner Formwork

In the steel and formwork equipment market, final pricing is generally calculated based on weight. Therefore, when purchasing metal corner formwork, having an approximate understanding of the component weight helps you estimate overall costs more accurately. The weight of corner formwork depends on three main factors:

- Steel Plate Thickness: A 3 mm plate is the standard market option, while 4 mm plates are used for heavy-duty projects.

- Manufacturing Method (Fabricated vs. Pressed): Pressed (bent) corners are typically lighter and more integrated, whereas fabricated (welded) corners are heavier but offer higher structural strength.

- Number of Stiffeners: The presence of reinforcing ribs or flat bars behind the corner increases both weight and load-bearing capacity.

For example, an external corner with dimensions (10 × 10) and a height of 1.5 meters will have a different weight compared to the same section with a height of 1 meter. Accurate weight calculation is essential for transportation planning and project budgeting.

The Quality Formula: How to Distinguish a Good Corner from a Poor One

When purchasing metal corner formwork, price should not be your only consideration. A low-quality corner may deform during the very first concrete pour, leading to significant repair or replacement costs. To evaluate the quality of Zeman-produced corner formwork and compare it with other products on the market, pay close attention to the following factors:

- Welding Quality: In fabricated (strip-welded) corners, where flat bars are welded to the base plate, weld seams must be continuous and free of porosity. Spot welding or weak welds may fail under concrete pressure. Zeman products utilize high-penetration CO₂ welding to ensure long-term durability.

- Bending Accuracy: In pressed corners, the bending angle must be exactly 90 degrees. Any deviation will cause instability when connected to adjacent panels, resulting in concrete leakage at the joints.

- Hole Positioning: Punching and pin/wedge holes must strictly comply with standard spacing and edge distances. Even a few millimeters of deviation can prevent proper pin insertion, forcing workers to use destructive hammering during installation.

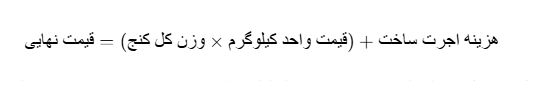

How Is the Purchase Price of Metal Corner Formwork Calculated?

The price of these components is directly influenced by the daily market price of steel plates (typically ST37 Mobarakeh steel). However, the general pricing formula can be summarized as follows:

src=”https://zemanco.com/wp-content/uploads/2025/12/Screenshot-2025-12-28-152553-1.png”

alt src=”https://zemanco.com/wp-content/uploads/2025/12/Screenshot-2025-12-28-152553-1.png”

alt

At Zeman Factory, we strive to minimize fabrication costs through optimized production lines and bulk procurement of raw materials, ensuring a competitive final price for our customers. Purchasing second-hand corner formwork is also an option for cost reduction; however, it involves risks such as deformation and metal fatigue and is not recommended for sensitive or high-precision projects.

To complete your connection system, keep in mind that in addition to corner formwork, you may also require tie rod bolts for connecting soldier beams, which are essential accessories in the formwork of tall concrete walls.

Guide to Estimating the Weight of Metal Corner Formwork (For Pricing Section)

Since steel is priced by weight, the following table is particularly useful for buyers. (Weights are approximate and calculated based on standard 3 mm steel plates.)

Approximate Weight Table for Metal Corner Formwork (kg)

| Corner Dimensions | Height: 1 m | Height: 1.5 m | Height: 2 m |

| External Corner (5 × 5) | ≈4.5 kg | ≈6.7 kg | ≈9 kg |

| External Corner (10 × 5) | ≈5.5 kg | ≈8.2 kg | ≈11 kg |

| External Corner (10 × 10) | ≈7 kg | ≈10.5 kg | ≈14 kg |

| Internal Corner (10 × 10) | ≈6 kg | ≈9 kg | ≈12 kg |

Ordering and Purchasing Process from Zeman

Purchasing internal and external metal corner formwork from the Zeman website follows a simple and transparent process:

- Drawing Review: First, review your project’s execution drawings. The number of columns, their dimensions, and wall areas determine the required quantity and type of corner formwork.

- Consultation: If you are unsure about calculating the exact number of corners, contact our technical team. Based on your drawings, our experts can prepare a precise Bill of Materials (BOM).

- Type Selection: Specify whether your formwork system uses 5 cm or 6 cm edge profiles, and whether you require pressed or fabricated corners.

- Order Placement: After receiving the proforma invoice and final confirmation, your order will be dispatched and delivered to the project site in the shortest possible time.

Conclusion

Corner formwork components are the silent heroes of concrete structures. Although they may represent a small portion of the total formwork purchase volume, their role in achieving perfectly squared columns and smooth walls is undeniable. By making the right selection and purchasing high-quality metal corner formwork from a reputable brand such as Zeman, you not only increase project execution speed but also avoid hidden costs associated with repairs and poor concrete finishes.

Contact us today for a price inquiry and expert consultation. Your structural quality is our guarantee.