What Is the Difference Between Scaffolding and Traditional Scaffolds?

In the construction industry, selecting the appropriate access system can make the difference between a successful project and one exposed to significant risks. If you are searching for an answer to the question, “What is the difference between scaffold and traditional scaffolding?”, it is important to understand that while these two terms are often used interchangeably, there are profound technical differences between them. Scaffold, which is sometimes referred to as modular scaffolding, represents more advanced systems specifically engineered for high load-bearing capacity. In contrast, traditional scaffolding is largely based on older, labor-intensive and manual methods. In this article, we provide an in-depth analysis of these differences. If you are planning to purchase scaffolding systems, this guide has been prepared for you:

Scaffold Price and Purchase Guide

A Brief History of Access Systems

The history of scaffolding dates back thousands of years, when ancient Egyptians used wooden structures to gain access to elevated areas. Modern scaffold systems, however, emerged in the 20th century alongside industrial advancements. In Iran, companies such as Zeman, with more than 35 years of experience, have localized and adapted these systems to meet modern construction standards.

What Is the Difference Between Scaffold and Traditional Scaffolding?

This question is one of the most common inquiries in the construction industry, where an incorrect choice can lead to increased costs, reduced safety, or even project delays. In this comprehensive and specialized guide—developed based on extensive research from reliable sources—we thoroughly examine definitions, differences, advantages, disadvantages, applications, standards, and selection criteria related to scaffold and traditional scaffolding systems.

In civil engineering projects, scaffolding is not merely a temporary structure for access at height; it is a critical engineering system responsible for structural support, providing safe access for workers, and ensuring overall site safety. However, the wide variety of

scaffolding systems

and associated technical terminology—particularly the distinction between “traditional scaffolding” and “scaffold”—often leads to confusion among contractors, engineers, and even workers. This confusion can result in improper system selection, which in turn has significant negative impacts on project scheduling, budget, and most importantly, safety.

This report aims to eliminate this ambiguity by presenting a comprehensive and detailed comparative analysis of traditional scaffolding systems (pipe and coupler) versus modern modular scaffold systems. The focus of this analysis includes various dimensions such as structural design, safety performance, economic justification, and application scope. The ultimate goal is to provide a practical, evidence-based guide that enables professionals to make the most informed decisions based on their specific project requirements. In this regard, by examining the key features of Zeman’s products—manufactured using advanced robotic production technologies that have defined new standards in the scaffolding industry—we arrive at a comprehensive and practical conclusion.

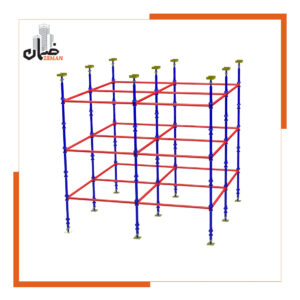

Scaffold systems are lighter than traditional scaffolding (approximately 20–30% lighter), and their installation speed can be up to 50% faster. These systems are capable of supporting loads of up to 5 tons, which is critical for large-scale projects such as bridge construction.

Definition of Traditional Scaffolding – A Conventional and Flexible System for General Access

Traditional scaffolding, also known as tubular scaffolding, has been widely used in Iran for several decades and is considered one of the oldest and most common scaffolding systems in construction projects. This system consists of separate standardized components. Its main elements include steel pipes with an outer diameter of 48.3 mm and variable thicknesses ranging from 2 to 5 mm, with the most commonly used thicknesses being 2 mm and 2.5 mm. These pipes are connected using specialized couplers such as right-angle couplers, swivel couplers, and single-bolt couplers, each serving a specific function.

The installation of traditional scaffolding is a specialized and time-consuming process that requires extensive knowledge and experience from skilled scaffolders. In this method, the scaffolder cuts the pipes to the required dimensions using specific tools and then connects them using couplers, bolts, and nuts.

Due to the heavy reliance on human skill, even minor errors or miscalculations during installation can seriously compromise structural safety. This type of scaffolding is primarily used to provide access for activities such as façade installation, painting, plastering, and high-elevation maintenance. One of its main advantages is its flexibility in adapting to complex and irregular building façades.

Traditional scaffolding includes a wide variety of types:

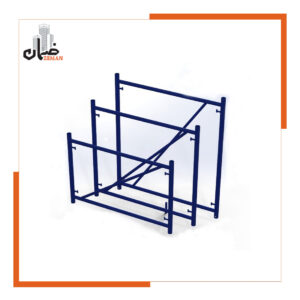

Traditional Simple Scaffolding: Made of steel pipes and manual couplers; suitable for building façade work.

H-Frame Scaffolding: Featuring an H-shaped structure for increased stability.

Service Scaffolding: Used for service operations such as maintenance and repair.

Definition of Scaffold – Advanced Modular Systems for Safe Access

The English term “Scaffold” generally means scaffolding. However, in the Iranian construction industry, this term is specifically used to denote prefabricated, modular metal scaffolding systems, reflecting a significant transformation in the industry. With the introduction of these systems, the need to distinguish them from traditional methods became so pronounced that a foreign term was adopted to represent a new technology. This demonstrates that the differences go far beyond terminology and are fundamentally structural and functional.

Scaffold systems consist of ready-made components with predefined spacing, transforming installation from a specialized craft into a simple and rapid assembly process. These characteristics provide significant advantages:

- Fast and Easy Installation: Due to prefabricated structures and simple connections, scaffold installation requires fewer skilled workers. In certain systems such as hammer-lock and cuplock scaffolding, installation can be carried out using only a hammer, without the need for complex tools—resulting in substantial savings in time and labor costs.

- Exceptional Safety: Standardized structures and precise locking mechanisms significantly reduce human error and provide inherently higher safety. Non-slip locking systems, such as those used in cuplock scaffolding, prevent accidental disengagement of connections and reduce the risk of falls.

- High Load-Bearing Capacity: Scaffold systems—especially triangular types—are capable of supporting heavy loads, making them highly suitable for demanding applications such as concrete formwork.

Types of Scaffold Systems in Building Construction

Scaffold systems are categorized into various types based on their design:

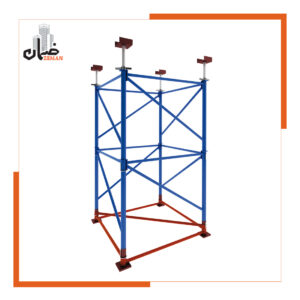

Triangular Scaffold (Omega Triangular Scaffolding): Featuring a triangular configuration, this system offers high structural strength and is ideal for supporting concrete slab formwork. For more information, refer to the Omega Triangular Scaffolding page.

Hammer Scaffolding: Equipped with wedge-lock connections, offering rapid installation and suitable for high-elevation applications. See details on the hammer scaffolding page.

Cuplock Scaffold: Featuring cup-shaped locking mechanisms, ideal for heavy load-bearing applications. Check pricing on the cuplock scaffolding page.

Classification and Fundamental Differences Between Scaffolding and Scaffold Systems

In a general definition, “scaffold” (scaffolding) refers to any temporary work platform used to transport workers, materials, or both at elevated heights. This term has a broad meaning and encompasses all types of access platforms, ranging from the simplest wooden platforms to the most advanced modular metal systems.

Based on this definition, traditional scaffolding is, in fact, a subset of scaffolding systems. More specifically, scaffolding refers to supported scaffolds—structures that rise from the ground and are supported by rigid and load-bearing components such as bases, frames, beams, or steel tubes.

In contrast, suspended scaffolds are hung from an overhead structure using ropes or non-rigid equipment and are typically used for activities such as washing, maintenance, or painting the façades of high-rise buildings.

This difference in the method of support forms the basis of scaffold classification. Supported scaffolds, which are the most commonly used systems in construction projects, are capable of carrying heavy loads of materials and equipment and must be properly braced to resist lateral forces such as wind.

This category includes various types such as frame scaffolding, tube-and-coupler (tube & clip) scaffolding, and advanced modular systems such as Cuplock and Ringlock scaffolding. On the other hand, although suspended scaffolds are sometimes designed to carry relatively heavy loads, they are primarily used for façade access and tasks such as painting, insulation installation, or light maintenance work.

Additionally, certain modern equipment such as scissor lifts and aerial lifts are also classified as supported scaffolds under OSHA definitions, even though they may not resemble traditional scaffolding systems at first glance.

Therefore, whenever a ground-supported work platform is used for concrete wall formwork or slab construction, it is, in fact, a type of supported scaffold—namely, traditional scaffolding.

Traditional scaffolding systems generally have a lower initial cost and greater flexibility in small-scale projects; however, their installation is time-consuming, requires more labor, and due to the heavy weight of components, imposes greater physical strain on workers.

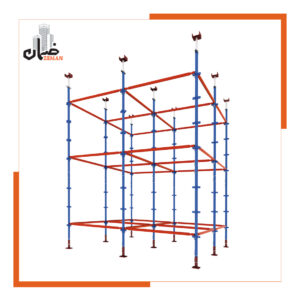

In contrast, system scaffolding or modular scaffolding represents a new generation of scaffolding composed of standardized, prefabricated components. Systems such as Cuplock scaffolding, hammer scaffolding, and H-frame scaffolding are equipped with special connections that make assembly and dismantling extremely fast. These connections—whether cuplock, ring-type, or pin-and-lock mechanisms—operate without bolts and nuts and are engaged simply by a hammer strike or a quick locking action.

This very difference in construction technology clearly defines the boundary between traditional scaffolding and modular scaffold systems: modular scaffolding is an engineered system designed to increase speed, safety, and durability, whereas traditional scaffolding relies primarily on installer skill and on-site flexibility.

Selection between the two depends entirely on project complexity, load-bearing requirements, structural geometry, and economic considerations.

Comprehensive Analytical Comparison: A Smart Choice for Every Project

Choosing between traditional scaffolding and various scaffold (modular) systems requires careful analysis based on multiple criteria. This decision should not be made solely on initial cost, but rather by considering factors such as speed, safety, and long-term costs.

Technical and Structural Comparison Table

| Criterion | Traditional Scaffolding (Tube & Coupler) | Triangular Scaffolding (Shoring) | Hammer Scaffolding |

| Connection Mechanism | Bolts, nuts, and right-angle and swivel couplers | Male–female interlocking (tool-free) | Hammer-lock connection (no wrench required) |

| Skilled Labor Requirement | High (specialized and time-consuming process) | Low (simple assembly by general workers) | Low (extremely fast and simple assembly) |

| Installation Speed | Slow and time-consuming | Fast | Very fast |

| Load-Bearing Capacity | Variable, dependent on installation quality and installer skill | Very high (up to 14 tons per square meter) | High (especially in star-head configurations) |

| Primary Application | Façade work, maintenance, painting | Slab formwork, bridge substructures | Industrial, refinery, and façade projects |

| Initial Cost | Lower than modular systems | Higher than traditional scaffolding | Higher than traditional scaffolding |

| Long-Term Cost | May be higher (due to increased labor costs) | Cost-effective (time and labor savings) | Cost-effective (time and labor savings) |

Economic Analysis and Investment Justification

Data shows that the initial cost of purchasing or renting scaffold systems is usually higher than that of traditional scaffolding. However, a more in-depth analysis reveals that focusing solely on initial cost can be misleading. The true economic justification lies in a comprehensive and long-term evaluation.

The exceptionally fast installation and dismantling of scaffold systems—made possible by their prefabricated connection mechanisms—directly leads to a significant reduction in labor costs and overall project duration. These savings easily offset the higher upfront cost and ultimately make scaffold systems a more economical option. In other words, a higher initial cost does not necessarily mean a higher total expense. Investing in scaffold systems is, in fact, a strategic decision to increase project speed and reduce long-term operational costs, thereby directly improving profitability. This analysis shifts contractors and engineers from purely price-based decisions toward strategic ones.

Safety and Key Standards

Safety is one of the most critical aspects of any scaffolding project. While the safety of traditional scaffolding is entirely dependent on the skill and experience of the scaffolder, scaffold systems offer inherently higher safety due to their modular design and precise locking connections, significantly minimizing human error.

In Iran, specific scaffolding standards are mandatory. These standards include the use of steel tubes with a diameter of 48 mm and a wall thickness of 2 to 3 mm, as well as maintaining a maximum spacing of 2 meters between vertical standards. In addition, to enhance worker safety, the use of protective guardrails at heights of 55 cm and 110 cm above the working platform is required. Other critical safety considerations include:

- Distance from power lines: Scaffolding must maintain a minimum distance of 1 meter from power lines below 300 volts and at least 3 meters from higher-voltage lines.

- Daily inspection: All scaffolding components and connections must be inspected on a daily basis to ensure proper performance.

- Quality of scaffold planks: Working planks must be sound, crack-free, with a minimum thickness of 5 cm and a minimum width of 25 cm.

The Role of Adjustable Props and Accessories in Completing the System

Adjustable props and support jacks play a complementary and vital role alongside scaffolding and scaffold systems, particularly in formwork operations. Adjustable props—including simple props, cross-head props, and U-head jacks—are directly responsible for temporarily supporting concrete slabs and decks during the concrete pouring and curing process. For example, in slab formwork projects, cross-head ceiling props are the optimal choice for supporting horizontal beams and the center of slabs.

The use of high-quality scaffold planks is also of great importance, as worker safety is directly dependent on the strength and stability of working surfaces. These planks must be installed firmly and evenly on the scaffolding system and protected against any slippage or displacement.

Conclusion: A Choice for the Future of Construction Projects

The difference between traditional scaffolding and scaffold systems goes far beyond a simple naming distinction; it represents a fundamental gap between two generations of construction technology. On one side stands traditional scaffolding, offering flexibility and lower upfront cost, and on the other, modular scaffold systems characterized by speed, safety, and long-term economic efficiency. Given modern industry trends and the growing emphasis on speed and safety, the transition from traditional systems to modular scaffolding is inevitable.

Traditional scaffolding consists of separate components—steel pipes and couplers—whose installation requires skilled labor and significant time, and is primarily used for façade access and height-related work. In contrast, scaffold systems (also known as modular scaffolding) are composed of prefabricated components that allow for extremely fast and straightforward installation.

The advantages of these modern systems include inherently higher safety due to standardized structures and rigid connections, impressive load-bearing capacity (especially in triangular systems for formwork), and reduced long-term project costs. Although the initial cost of purchasing or renting scaffold systems is generally higher than that of traditional scaffolding, the substantial savings in labor and time make them an economical and profitable choice.

Zeman Company, relying on fully robotic manufacturing technology and delivering products that meet the highest quality standards, acts as a pioneer in this field by helping contractors and engineers make informed decisions to ensure project safety and success. Utilizing Zeman’s products and consulting with the company’s technical experts is a vital step toward advancing construction projects into a safer and more efficient future.

To view Zeman products, click here: Concrete Formwork Equipment

Frequently Asked Questions About Scaffolding and Scaffold Systems

In this section, we answer the most important and frequently asked questions regarding scaffolding and scaffold systems and the differences between them, so that you can make a more informed purchasing decision.

What is the load-bearing capacity of triangular scaffolding?

Triangular scaffolding, due to its geometric configuration and rigid connections, offers exceptionally high load-bearing capacity. When properly installed, this system can support loads of up to 14 tons per square meter, making it ideal for heavy slab formwork and bridge substructures.

Why is Cuplock scaffolding safer?

Cuplock scaffolding features a unique cup-locking mechanism that is activated with a single hammer strike, providing very high safety. This system creates a completely rigid, play-free connection that is highly resistant to vibration and dynamic loads. As a result, human error during installation is minimized and the risk of accidents is significantly reduced.

How is the price difference between traditional scaffolding and scaffold systems justified?

Despite the higher initial cost of scaffold systems, their economic justification lies in long-term savings. The extremely fast installation speed of scaffolding—requiring less labor and shorter project duration—results in significant savings in wages and time, increasing overall project profitability and fully justifying the upfront investment.

Is modular scaffolding suitable for every project?

Although modular scaffolding systems are efficient for many projects, selecting the appropriate type depends on specific project requirements. For example, triangular scaffolding is suitable for slab and bridge formwork, while H-frame systems are ideal for small to medium-sized projects such as façade work and plastering.

How can high-quality scaffolding be identified?

To identify high-quality scaffolding, factors such as technical specifications (standard weight and thickness), raw material quality, welding quality, and overall appearance must be evaluated. Quality steel tubes should be free from warping and corrosion, and their weight should be close to standard Stahl specifications. Purchasing from reputable manufacturers such as Zeman Company, which holds quality certifications, guarantees product authenticity and reliability.

What is the role of adjustable props in conjunction with scaffold systems?

Adjustable props and support jacks are vital components used alongside scaffold systems to temporarily support concrete slabs and decks during formwork operations. They assist in leveling and stabilizing the structure prior to concrete pouring and ensure structural integrity until the concrete has fully cured.