Different Methods of Swimming Pool Concrete Placement

Swimming pool construction, particularly concrete swimming pools, is considered one of the most complex and sensitive engineering processes in the construction industry. Despite the emergence of alternatives such as fiberglass and vinyl pools, concrete remains recognized as the gold standard in terms of durability, design flexibility, and enhancement of property value. The primary and unparalleled advantage of concrete lies in its unlimited customization capability; employers and designers can execute pools in any size, depth, and geometric shape, ranging from classic rectangular designs to organic and free-form structures.

The success of constructing a concrete swimming pool depends on three key factors:

- Accurate engineering design

- Flawless execution

- Selection of standard-compliant equipment

Among these factors, the concrete placement method plays a pivotal role and determines the overall project trajectory in terms of time, cost, and final quality. There are three primary approaches for executing the concrete structure of a swimming pool, each with its own advantages, disadvantages, and specific technical requirements:

- Cast-in-place concrete (formwork method)

- Shotcrete (sprayed concrete)

- Use of precast components

However, the final quality of a concrete swimming pool depends not only on the execution method but also heavily on the quality and standard of the equipment used, including concrete formwork systems, modern scaffolding, and connections. The use of inappropriate equipment can lead to structural defects, inadequate waterproofing, deformation of walls, and ultimately, substantial future repair and maintenance costs. This comprehensive report adopts an engineering and technical approach to provide an in-depth analysis of each of these methods and explains the critical role of supporting equipment at every stage, serving as a complete guide for contractors, engineers, and employers in the construction of a durable and defect-free swimming pool.

Prerequisites for Pool Concreting – Preparation Stages

Before the first cubic meter of concrete is poured at the project site, a series of precise and vital actions must be carried out. These stages form the foundation of the entire project, and any negligence during this phase can jeopardize the quality and durability of the entire structure.

Phase 1: Engineering Design, Permits, and Proper Excavation

The starting point of any swimming pool construction project is a precise and engineered design. These plans, which must be prepared by an experienced civil engineer or architect, are not limited to dimensions and appearance; they also include structural details such as wall and floor thickness, precise floor slopes for proper drainage, and the exact locations of inlet and outlet utilities. Selecting a suitable location for the pool is also of great importance; a flat area away from trees can significantly reduce excavation costs and future maintenance requirements.

After finalizing the design, excavation operations begin according to the specified dimensions. Following excavation, stabilization and leveling of the subgrade are critically important. Executing a blinding concrete layer with a thickness of 5 to 10 centimeters at the bottom of the excavation provides a uniform and stable surface for subsequent stages and prevents direct contact between the reinforcement mesh and the soil.

Phase 2: Reinforcement Installation – The Steel Skeleton of the Pool

Reinforcement acts as the steel skeleton of the swimming pool, providing the tensile strength required to withstand hydrostatic water pressure and the forces exerted by the surrounding soil. This process involves installing a meshed network of steel rebars in the pool floor and walls. One of the most critical technical considerations at this stage is the correct connection of the vertical wall rebars to the floor reinforcement mesh. These rebars must be fully anchored into the floor concrete to form a unified and integrated structure, preventing the formation of cold joints at the wall-to-floor connection.

To ensure long-term durability of the structure, providing adequate concrete cover over the rebars is essential. This cover prevents direct contact between the steel and water or corrosive agents, thereby avoiding rusting and structural deterioration. For this purpose, components known as spacers or plastic chairs are used to maintain a specific distance between the reinforcement network and the formwork surface or soil.

Phase 3: Installation of Mechanical and Electrical Systems

One of the most sensitive stages prior to concreting is the precise positioning and installation of the circulation and filtration system piping, as well as the electrical wiring related to pool lighting. These installations must be fully completed and tested before concrete pouring begins. Any error or leakage at this stage, once the concrete has hardened, can only be corrected by demolishing parts of the structure and incurring extremely high costs.

This sequence of operations creates a critical dependency within the project workflow. Any delay in the supply or installation of plumbing and electrical systems will directly halt the entire construction process. Since concreting operations are among the most expensive and time-consuming phases of the project, any stoppage results in idle costly equipment and specialized labor. This highlights that the primary risk in pool construction is not limited to structural challenges alone but is heavily influenced by coordination and management of the supply chain and early-stage contractors. A successful project manager must prioritize the timely completion of these preliminary stages.

Cast-in-Place Concrete Method; Precision and Strength Through Engineered Formwork

The cast-in-place concrete or formwork method is the most traditional and widely used approach for constructing concrete swimming pools. In this method, fresh concrete is poured into pre-installed and precisely assembled formwork, allowing it to take the final shape of the structure after hardening. This approach remains highly popular due to its ability to provide precise control over concrete quality, wall thickness, and smooth surface finishes. However, this method is significantly time-consuming, and the costs associated with formwork preparation and execution constitute a substantial portion of the project budget.

The Art of Formwork: Shaping the Pool Structure

Formwork is a temporary structure responsible for shaping and supporting plastic concrete until it reaches its initial strength. The selection of the type and quality of concrete formwork systems has a direct impact on the final surface quality, dimensional accuracy, and overall project costs.

Types of Formwork Systems in Pool Concrete Construction

Various types of formwork, such as timber, steel, and fiberglass forms, can be used for pool construction. Among these, modular steel formwork is recognized as an optimal and economical option in modern projects due to its high durability, reusability, rapid assembly, and ability to produce very smooth surfaces. Modular formwork systems, utilizing panels with standardized dimensions, accelerate the installation and dismantling process while minimizing material waste. These panels are connected using formwork accessories such as pins and wedges, forming an integrated and robust structure.

Alongside steel formwork, formwork plywood and timber beams also play a significant role. Purchasing high-quality formwork plywood with a waterproof coating, combined with the use of H20 timber beams as supports, can create perfectly smooth and exposed concrete surfaces. This reduces the need for costly finishing layers and provides a modern aesthetic to the structure. Due to its high resistance to moisture and the pressures exerted by fresh concrete, plywood is an ideal choice for this application.

Formwork of Pool Walls

Formwork of pool walls is one of the main challenges of this method and requires a high level of precision and expertise.

Straight Walls

For swimming pool walls, double-sided wall formwork is typically used. In this system, two formwork panels are installed on both sides of the wall and restrained at a specified distance from each other using tie bolts that pass through the wall. In situations where access to one side of the wall is not possible (such as walls supported by excavation faces), one-sided wall formwork is applied, in which the lateral pressure of the concrete is resisted from only one side using robust supporting structures.

Special Walls and Columns

For pools with special architectural designs, more advanced techniques are required. Curved wall formwork is executed using prefabricated arched panels or by assembling narrow modular formwork panels to accurately achieve the desired curvature.

In addition, when high-quality final surfaces with an aesthetic appearance are required, special considerations are applied for architectural façade wall formwork. In some complex designs involving structural elements such as decorative columns or small bridge supports over pools, rectangular column formwork, square column formwork, and circular column formwork methods are utilized.

Square or Rectangular Column Formwork

Stable Supports: The Role of Props and Supporting Structures

The stability and resistance of the formwork system against the immense hydrostatic pressure of fresh concrete are ensured by props and supporting structures.

A detailed review of the equipment required for the cast-in-place method reveals an important logistical and economic reality. Projects with complex designs, such as pools with curved walls or decorative columns, require a wide range of specialized equipment, from curved wall formwork to alignment props and various wall and column support props.

Smaller contractors rarely own all of this equipment. This reliance on the equipment rental market or the risk of performing work with unsuitable tools transforms the cast-in-place method from a purely technical decision into a strategic logistical and financial challenge. Consequently, methods such as shotcrete or precast construction become more attractive to contractors with limited equipment investment.

Using wall and column support props to stabilize formwork is critical. The guide to purchasing shoring and support props should be based on the structure height and applied loads. For lighter loads, simple shoring props can be used, while purchasing U-head props is more suitable for placement beneath beams and horizontal walers due to the special shape of the prop head.

To ensure the vertical alignment of walls and prevent deviation from plumb during pool concreting, the use of alignment props is essential. These props are connected to the vertical walers of the formwork and, through adjustable length mechanisms, stabilize the formwork in a perfectly vertical position.

Shotcrete Method (Sprayed Concrete); Speed and Design Flexibility

Shotcrete, or sprayed concrete, is a modern and efficient method for pool construction in which the concrete mix is projected at high air pressure through a nozzle onto the reinforcement network. Due to its high execution speed and exceptional flexibility in forming complex and curved shapes, this technique is especially popular in luxury projects and water parks.

Process Analysis

Shotcrete is executed using two main methods:

- Dry process: In the dry method (also known as gunite), dry materials are conveyed to the nozzle under air pressure and mixed with water at the point of discharge.

- Wet process: In the wet method, fully mixed concrete is pumped and then sprayed. In general, wet shotcrete provides higher final quality due to better control of the water-cement ratio and reduced dust generation.

Advantages and Disadvantages

The primary and undeniable advantage of this method is its high execution speed and the elimination of complex and time-consuming formwork. This makes shotcrete an ideal solution for constructing pools with organic, free-form, and curved geometries. However, this method also has drawbacks. The high cost of specialized equipment (pump and nozzle) and the requirement for highly skilled and experienced operators are its main challenges. The final quality of the structure, including concrete compaction and uniform thickness, is heavily dependent on the operator’s skill and precision.

Providing Access and Safety with Specialized Scaffolding

For safe and efficient shotcrete application, especially on high walls, establishing a stable working platform for operators and equipment is essential. This is where modern scaffolding systems play a key role.

Service scaffolding is used to access all areas of the wall. The safety of these working platforms is ensured by purchasing standard and durable scaffold boards. The price of scaffold boards varies depending on the material (wooden or steel) and dimensions and must be considered as part of the project’s safety costs.

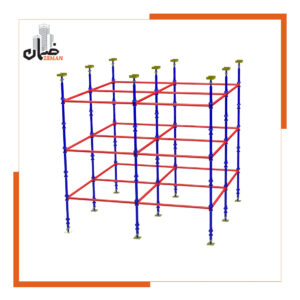

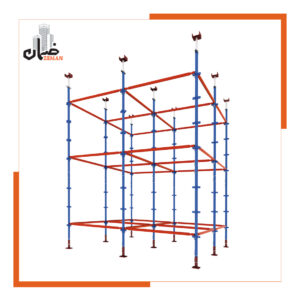

Modular scaffolding systems, generally referred to as scaffold systems (scaffold price and purchase), are ideal options for shotcrete projects due to their rapid assembly, high safety level, and suitable load-bearing capacity.

These systems, also known as cuplock scaffolding, are among the most popular types of modular scaffolding. Their connections are made using cup locks and secured quickly with hammer strikes, without the need for wrenches. This feature significantly increases erection speed. Although the price of cuplock scaffolding may initially be higher than traditional scaffolding, considering its execution speed and reusability, it is regarded as a long-term and cost-effective investment.

Hammer scaffolding, which includes cup-type and star-type systems, is assembled by hammering in a manner similar to cuplock scaffolding. Due to its high structural strength, it is suitable for carrying heavy loads and creating large working platforms.

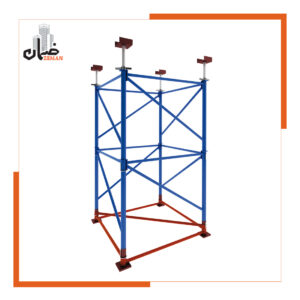

Triangular Omega scaffolding, also known in the market as triangular shoring, consists of triangular frames that are connected together using male and female joints. The triangular structure provides exceptionally high load-bearing capacity, making it suitable not only for façade scaffolding but also for shoring and formwork support of heavy concrete slabs.

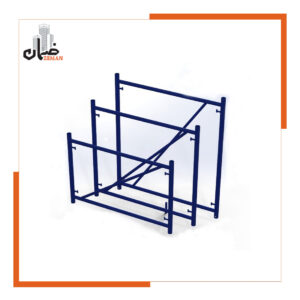

H-frame scaffolding, also known as frame scaffolding, consists of prefabricated H-shaped frames that are rapidly assembled on top of each other and are used to quickly create stable working platforms at various heights.

Precast Method – Innovation in Pool Construction

The use of precast concrete components represents a modern approach in the pool construction industry, based on the principles of industrial production and rapid on-site installation. In this method, pool walls and sometimes the floor are produced as reinforced concrete panels in a controlled factory environment and then transported to the project site for installation.

Process Analysis

The process begins with the production of panels in the factory. The quality, dimensional accuracy, and surface smoothness of these components are directly dependent on the quality of the precast concrete molds. These precise and engineered molds enable mass production of components with uniform and standardized quality. After transportation to the site, the panels are positioned and connected using mechanical joints and concrete casting at the joints, followed by proper waterproofing.

Precast Concrete Component Molds

Advantages and Limitations

The greatest advantage of this method is the extremely high speed of on-site installation. Since most of the construction process is completed in the factory, on-site operations are reduced to just a few days. Factory-based quality control also ensures high strength and durability of the components. However, this method has limitations. Design flexibility for complex and curved forms is lower compared to shotcrete, and challenges related to transporting heavy components as well as achieving precise and durable joint waterproofing are critical technical considerations.

Technical Analysis and Concrete Curing Process for Pools

Regardless of the selected pool concreting method, the quality of the concrete itself and the curing process are decisive factors in durability, waterproofing, and service life. Pool concrete must be considered a special hydraulic structure requiring precise technical specifications.

Pool Concrete Specifications

For pool construction, the use of concrete with a cement content of at least 350 and preferably 400 kilograms per cubic meter is recommended. A higher cement content results in greater density, lower permeability, and higher compressive strength. Additionally, the water-to-cement ratio (W/C) must be carefully controlled and kept below 0.5, as reducing this ratio significantly enhances concrete strength and durability.

The Role of Admixtures

The repeated emphasis on specialized concrete admixtures (such as microsilica, waterproofing agents, and plasticizers) reflects a fundamental transformation in concrete technology. Concrete has evolved from a simple mixture (cement, sand, and water) into an engineered composite material. As a result, constructing modern and durable pools now requires a deeper understanding of material science, obligating contractors to comprehend chemical interactions and performance characteristics of these admixtures.

Consequently, a new market has emerged for specialized concrete suppliers and materials consultants. Simply specifying a 400-grade concrete is no longer sufficient; instead, the entire admixture package must be engineered for the specific application, namely a water-retaining structure.

The use of concrete admixtures to enhance properties is essential. Plasticizers (water-reducing agents) improve workability without adding excess water. More importantly, waterproofing admixtures such as microsilica gel fill microscopic pores within the concrete structure, drastically reducing permeability and, in many cases, eliminating the need for secondary waterproofing layers such as bituminous membranes or resins.

Compaction and Curing

After placing or spraying the concrete, proper compaction is essential to eliminate entrapped air voids. This is typically achieved using needle vibrators and helps produce a uniform and monolithic concrete structure.

The final and perhaps most critical stage is concrete curing. To achieve its designed maximum strength, concrete requires sufficient moisture during the early days. Rapid surface drying leads to surface cracking and reduced durability. Therefore, the concrete surface must be kept continuously moist for at least 7 to 14 days, either through regular water spraying or covering with wet burlap.

Conclusion and Smart Selection

Selecting the optimal pool concreting method is a multi-dimensional decision that must consider technical, economic, and scheduling factors. Each of the three main methods—cast-in-place (formwork), shotcrete, and precast—has unique advantages and limitations, making them suitable for different scenarios.

- Cast-in-Place Method (Formwork): Due to precise control over dimensions and quality, this method is the best choice for pools with standard designs (such as rectangular shapes), where structural durability is the main priority and strict time constraints do not exist.

- Shotcrete Method: Ideal for projects where execution speed is critical and designs include free-form, curved, and complex shapes. The success of this method heavily depends on access to skilled operators and specialized equipment.

- Precast Method: Suitable for projects where rapid on-site installation is the absolute priority, such as mass housing developments or agricultural pools. In this method, the client must adapt to factory-standard designs and limitations.

To facilitate decision-making, the following table provides a comprehensive comparison of these three methods based on key criteria. It summarizes the technical analyses into a strategic decision-making tool, allowing project managers or clients to quickly evaluate various factors and select the method aligned with project priorities such as cost, time, or design flexibility.

| Criterion | Cast-in-Place Method (Formwork) | Shotcrete Method | Precast Method |

|---|---|---|---|

| Initial Cost | Medium to High (depending on formwork complexity) | High (equipment and skilled labor) | High (factory production costs) |

| Execution Speed | Slow | Very Fast | Fastest (installation phase) |

| Design Flexibility | Good (excellent for curved shapes with proper formwork) | Excellent (ideal for free-form and organic shapes) | Limited (dependent on factory models) |

| Durability and Integrity | Excellent (monolithic structure if properly executed) | Excellent (seamless structure without cold joints) | Good (dependent on joint waterproofing quality) |

| Need for Skilled Labor | Medium (skilled formwork workers) | Very High (shotcrete machine operators) | Medium (skilled installation team) |

| Ideal Application | Residential and public pools with standard designs | Luxury pools, water parks, special shapes | Mass construction projects, agricultural pools |

Final Conclusion

Ultimately, it must be emphasized that no single method is absolutely “the best.” The optimal choice results from a balanced consideration of project budget, expected timeline, design complexity, and available technical expertise. The long-term success of a concrete pool is achieved through a combination of selecting the appropriate method, precise and engineered execution, and, most importantly, the use of standardized, high-quality equipment. Investing in precise formwork systems such as modular steel formwork and safe, modern scaffolding systems is not a cost, but a guarantee of quality, durability, and structural safety that will deliver years of enjoyment and comfort.