Ways to Reduce Concrete Formwork Costs

In the modern construction industry, where material and labor costs continue to rise day by day, intelligent management of concrete formwork costs has become a necessity. Concrete formwork not only forms the foundation of concrete structures, but it can also consume up to 60 percent of the total project budget and have a direct impact on profitability. The good news, however, is that by adopting strategic approaches, these costs can be significantly reduced without sacrificing quality, safety, or structural durability.

This comprehensive article, developed based on practical experience and extensive research in the construction industry, provides an in-depth analysis of the factors affecting costs, practical optimization strategies, and real-world examples from successful projects. Our goal is to present a step-by-step guide that engineers, contractors, and project managers can easily apply in their daily work.

Main Factors Increasing Concrete Formwork Costs

First, let us review the main factors contributing to increased concrete formwork costs. These costs are generally divided into two categories: fixed and variable.

- Fixed costs include the purchase or rental of formwork systems, auxiliary equipment such as formwork accessories (including pins and wedges, clamps, and formwork tie rods), as well as initial design and engineering costs.

- Variable costs include labor, transportation, maintenance and repairs, and even material waste caused by execution errors.

According to industry statistics, improper design can increase costs by up to 20 percent, while unskilled labor may double execution time. To better understand these factors, you can refer to the Comprehensive Guide to Concrete Efflorescence, which demonstrates how quality issues caused by poor formwork lead to additional costs.

Key Tips for Reducing Concrete Formwork Costs in Construction Projects

- Optimizing the initial project design: By simplifying shapes and standardizing dimensions such as columns and beams, the need for custom formwork can be reduced, resulting in significant savings depending on project complexity.

- Selecting reusable and modular formwork systems: Using modular systems such as metal or plastic formwork that can be reused multiple times offsets higher initial costs and delivers long-term savings, especially in large-scale projects.

- Investing in skilled labor and training: Trained workers can reduce assembly and dismantling time, but a balance between training costs and productivity must be maintained to preserve quality.

- Using technology and precise planning: Tools such as BIM and CAD software can reduce material waste, although their impact may be less significant in small projects.

- Regular maintenance and repair of equipment: Proper maintenance extends the service life of formwork and reduces replacement costs, but it requires ongoing planning.

- Considering external factors such as transportation and rental: Choosing rental or second-hand formwork can be more economical in certain cases, provided quality is carefully inspected to avoid potential issues.

The Importance of Cost Management in Concrete Formwork

In construction projects, concrete formwork often accounts for more than 50 percent of structural costs. By focusing on practical strategies, costs can be managed without reducing quality. For example, selecting modular concrete formwork systems can significantly increase execution speed.

The Role of Materials and Equipment in Cost Efficiency

Selecting durable materials such as curved metal formwork or slab props helps reduce maintenance costs. In addition, reviewing the Comprehensive Guide to Concrete Column Formwork can provide practical insights.

Project Management and Scheduling

Accurate scheduling using digital tools can significantly reduce delays. For more information, refer to What Is Shoring?.

The Role of Initial Design in Reducing Concrete Formwork Costs

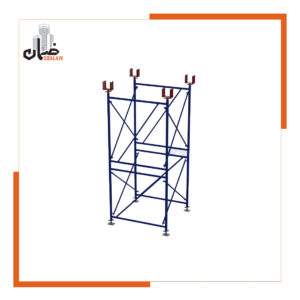

One of the most critical strategies is optimizing the initial project design. Design should focus on simplifying shapes and standardizing dimensions. For example, if column dimensions are identical across all floors, a single adjustable column formwork system can be used, eliminating the need to fabricate new formwork for each level. This approach not only reduces material costs but also shortens assembly time.

In large projects, the use of Building Information Modeling (BIM) software can deliver accurate demand forecasting and reduce waste by up to 15 percent. Early coordination between architects and structural engineers is also essential; standardizing beam and column widths can resolve connection challenges and eliminate the need for additional soldiers.

ZEMAX Adjustable Column Formwork

The Importance of Proper Materials and Equipment in Final Cost

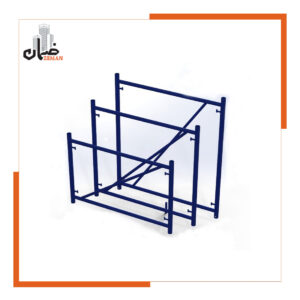

Selecting appropriate materials and formwork systems plays a vital role in cost reduction. Modular systems such as strapped metal formwork or ECO form are excellent choices because they are adjustable to various dimensions and can be reused many times.

Compared to traditional wooden formwork, which deteriorates after limited use, metal or plastic formwork can be reused up to 100 times, dramatically lowering the cost per use. Additionally, using plywood and timber beams for large surface coverage can reduce concrete waste. In commercial projects, selecting prefabricated systems such as tunnel formwork can reduce execution time by up to 30 percent, directly lowering labor costs.

Labor Management and the Importance of Training

Managing and training labor is another critical aspect. Skilled workers can assemble and dismantle formwork more quickly, but initial training costs may be challenging. To address this, investment in short-term training programs is recommended; for example, training on cuplock scaffolding can improve safety and speed. Reducing reliance on manual labor through automated systems such as assembly robots is also cost-effective in large projects. In a residential project case study in Tehran, training the execution team reduced slab formwork time from 5 days to 3 days and lowered total costs by 12 percent.

The Role of Modern Technologies in Cost Reduction

Utilizing modern technologies can be transformative. Tools such as augmented reality (AR) for installation guidance or 3D printing for complex formwork can reduce design and fabrication costs. Additionally, using high-quality concrete release agents facilitates easier stripping and extends formwork lifespan. For more information on innovative systems, refer to Wall Mesh: A Comprehensive Guide to a Modern Seismic Restraint System, which demonstrates how technology integrates into construction.

Proper Maintenance of Formwork and Equipment

Regular maintenance and repairs should not be overlooked. After each use, formwork must be cleaned, oiled, and stored in a dry environment. This practice can double the service life of H-frame scaffolding. Renting second-hand formwork from reputable suppliers can be a cost-effective option for short-term projects, but quality inspection is essential to prevent issues such as concrete leakage.

Case Studies on Reducing Formwork Costs

To better understand these concepts, let us review several case studies. In a commercial project in Europe, using modular plastic formwork systems reduced formwork costs by 25 percent due to shorter execution time and reduced material waste. In Iran, during the construction of a residential complex, standardizing column dimensions using dedicated formwork systems resulted in 18 percent cost savings. The table below presents a comparison of various systems:

| Formwork System | Initial Cost (IRR/m²) | Reusability | Assembly Time (hours/100 m²) | Overall Savings (%) |

|---|---|---|---|---|

| Traditional Wooden | 500,000 | 5–10 times | 20 | 10 |

| Modular Metal | 1,200,000 | 50–100 times | 10 | 30 |

| Prefabricated Plastic | 900,000 | 30–50 times | 8 | 25 |

| Tunnel Form | 1,500,000 | 100+ times | 6 | 40 |

This table is based on average figures from the Iranian market and international data, demonstrating that investment in advanced systems such as scaffolding systems can deliver high returns.

Environmental Approaches and Cost Savings

Beyond technical solutions, paying attention to environmental considerations can also reduce costs. Using recyclable materials such as recycled plastic formwork or low-energy systems not only complies with Iranian environmental regulations but can also generate savings through reduced disposal costs and government incentives.

For example, in green projects, using concrete with water-reducing admixtures can decrease formwork volume and lower costs. Future trends such as using artificial intelligence to predict formwork requirements or automated robots for assembly promise further cost reductions. In Iran, given economic challenges, focusing on domestic suppliers such as Zeman can reduce dependency on imports and stabilize costs.

Ultimately, reducing concrete formwork costs requires a comprehensive and integrated approach that includes precise planning, smart material selection, workforce training, technology adoption, and regular maintenance. By implementing these strategies, construction projects can become more economical, faster, and more sustainable. For professional consultation and access to innovative products, visit Zemanco, where advanced solutions such as the Comprehensive Guide to Reinforced Concrete Couplers are available.

Concrete Formwork Cost Management: A Comprehensive Guide for Construction Projects

In modern construction projects, where material and labor costs continue to rise, intelligent management of concrete formwork costs has become one of the most essential skills for engineers and contractors. Concrete formwork can account for up to 60 percent of the cost of concrete structures, and any poor decision in design, execution, or formwork selection can directly affect project profitability.

Based on field experience and reliable construction industry data, this article examines cost-influencing factors, practical cost-reduction methods, case studies, and optimal selection of formwork systems. The objective is to provide a practical, step-by-step guide that can be easily implemented in real-world projects.

Summary: Reducing Concrete Formwork Costs

Reducing concrete formwork costs is the result of a comprehensive strategy that includes:

-

Accurate planning

-

Correct selection of materials and formwork systems

-

Workforce training

-

Utilization of modern technologies

-

Proper equipment maintenance

By applying these methods, construction projects will become more cost-effective, faster, and more sustainable. For further guidance and access to standard equipment, consulting reputable suppliers in the formwork industry is strongly recommended.