What Is Exposed Concrete Formwork? Advantages_Disadvantages_Purchase_and Price

Exposed concrete, as one of the modern construction materials, functions beyond a mere structural element and has transformed into a key component in contemporary designs. Achieving a smooth, polished, and flawless final surface in this type of concrete is entirely dependent on the quality and type of formwork used. In this comprehensive report, we will conduct a specialized examination of exposed concrete and the necessary tools required to create its aesthetic appeal.

This text serves as a complete guide for engineers, architects, and contractors to become familiar with various types of formwork, supporting scaffolding systems, props, and connections, enabling them to bring architectural visions into reality with engineering precision. This report, by focusing on the principle that formwork is not merely a tool but plays a decisive role in the final quality and success of a project, introduces the position of ZAMAN products as a comprehensive and pioneering solution in this industry.

A New Perspective on Exposed Concrete and the Role of Formwork

For a long time, concrete was known only as a hidden structural material within buildings. However, in recent decades, it has undergone a profound transformation, establishing its position as a design and aesthetic material in modern architecture. This evolution led to the emergence of “Exposed Concrete”; concrete whose final surface, instead of being covered, is displayed as part of the building facade or interior decoration.

From bold European projects to landmark structures in Iran such as the Tehran Museum of Contemporary Art and Imam Khomeini International Airport, exposed concrete has become a symbol of simplicity, minimalism, and industrial beauty.

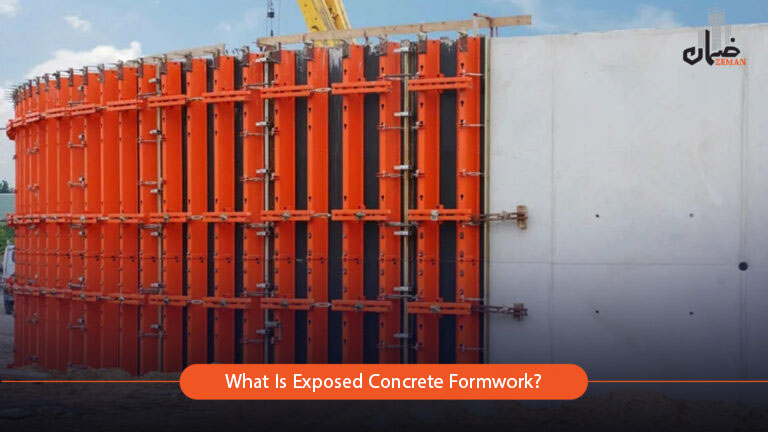

In exposed concrete projects, the quality and final appearance of the surface hold exceptional importance. This is where the role of formwork elevates from a simple tool for holding fresh concrete to an “Artistic Mold.” Exposed concrete formwork is not just a container; it is the factor that determines the texture, smoothness, and visual integrity of the final product. Unlike structural concrete, which is covered by other materials after curing, any defect or unevenness on the surface of exposed concrete is irreparable.

Therefore, the precise selection of formwork, concrete formwork systems, supporting props, and connections is the most crucial and sensitive stage in guaranteeing the success of an exposed concrete project. This report analyzes this hidden and vital factor, examining its various dimensions from technical and executive perspectives.

From Concept to Execution: What is Exposed Concrete?

Exposed concrete refers to concrete whose surface, after stripping the forms, is visible as part of the architectural design, interior decoration, or exterior facade of a building. This material possesses a unique texture, color, and appearance and often differs from structural concrete. Contrary to the common assumption that exposed concrete is merely structural concrete with surface finishing, its production requires specific processes and precise materials to achieve the desired result.

For instance, in the production of exposed concrete tiles, advanced technologies such as Ultra-High Performance Concrete (UHPC) are utilized, which provide very high compressive and flexural strength with minimal thickness. This combination is achieved using 12 different materials, which increases the mechanical resistances of the concrete.

Types of Exposed Concrete: Cast-in-Place vs. Precast

Exposed concrete is produced and executed in two main ways, each having specific advantages and applications:

Cast-in-Place Exposed Concrete

In this method, the concrete is poured on-site directly into the forms. This method is used for executing large and monolithic structures such as tall walls, vast ceilings, airport bases, and museums. The success of cast-in-place execution depends precisely on the selection of concrete formwork systems and the concrete mix design.

Precast Exposed Concrete

In this method, concrete panels and tiles of specific dimensions are manufactured in a controlled factory environment and then transported and installed at the project site. The main advantage of this method is high quality control, achieving appropriate density and strength, and significantly reducing project execution time. Due to the use of UHPC technology, these panels are lighter and highly suitable for modern building facades. Manufacturing companies like ZAMAN offer concrete precast element formwork for this purpose.

Technical Specifications and Applications of Exposed Concrete

Exposed concrete has notable technical specifications that distinguish it from other materials. Its specific gravity is about 1500 kg/m³, its compressive strength can reach up to 380 MPa, and its service life is estimated between 70 and 90 years. This material is resistant to atmospheric agents such as moisture, temperature variations, and abrasion, and is a suitable insulator against sound and heat.

The applications of exposed concrete are very diverse and include the following:

- Building Facades: Due to high resistance and modern appearance.

- Interior and Exterior Walls: Including garden walls, villas, and industrial spaces.

- Flooring: Suitable for parking lots, courtyards, and high-traffic areas.

- Urban Furniture and Decorative Elements: Construction of benches, fountains, and partition railings.

This diversity of application reflects the dual nature of exposed concrete. It is both a luxurious and decorative element in interior design and a highly resistant and durable structural component. These characteristics create a need for formwork tools and systems that can satisfy the aesthetic requirements of architects while meeting high engineering standards to withstand structural loads and environmental conditions. The selection of the appropriate formwork is the bridge that connects these two worlds, ensuring the final result is both visually appealing and structurally flawless.

Types of Exposed Concrete Formwork and Criteria for Selection

The choice of exposed concrete formwork depends on several factors, the most important of which include: the desired texture and appearance for the final surface, ease and speed of execution, durability and reusability, and costs. The formwork material must be compatible with the concrete mix and not react chemically with it. Furthermore, the formwork must be sturdy and durable, and its components must be capable of being disassembled and reshaped.

Metal Formwork for Exposed Concrete: High Durability and Precision

Metal formwork for exposed concrete, due to its high strength and durability, is a popular choice for projects requiring a very smooth and polished surface. These forms increase work speed and ease and have high reusability. However, their price is usually higher than other types of formwork. Metal forms require oiling to prevent the concrete from sticking to their surface. Manufacturers produce modular metal formwork using the highest quality steel sheets and precise welding, which significantly increases their strength and lifespan.

Wooden and Plywood Formwork for Exposed Concrete: Aesthetics and Flexibility

Wooden and plywood formworks are widely used in exposed concrete projects focused on aesthetics due to their ability to create special textures, such as wood grain or fabric patterns. These forms are lightweight and easy to transport, which increases the speed of execution.

However, the use of these forms involves important considerations. Their number of uses is less than that of metal forms, and the natural defects of the wood may affect the concrete’s pattern. Additionally, plywood sheets lose their effectiveness, especially in humid areas, and after use, they cannot be sold or recycled due to moisture absorption. This turns the high initial cost of plywood, which is often supplied as an import, into an economic challenge.

Although plywood may seem economical due to its reusability potential, the hidden costs associated with maintenance, vulnerability to moisture, and lack of recyclability necessitate a comprehensive economic analysis. In contrast, polymer forms can be sold and recycled after use, recovering the investment value. To complete the wooden formwork system, support equipment such as plywood and H20 wooden beams are also used for formwork procurement.

Plastic and Paper Formwork for Exposed Concrete

Plastic forms have become a cost-effective and fast alternative to metal and wooden forms due to their light weight, high resistance to moisture, and reusability for up to 50 times. These forms do not require oiling and increase project execution speed due to their low weight. Paper forms are used once for creating delicate and special designs in decorative projects.

Ultimately, selecting the appropriate formwork requires a deep understanding of the advantages and disadvantages of each material. The table below provides a comprehensive comparison between the types of exposed concrete formwork.

| Form Type | Durability & Uses (Cycles) | Final Surface Quality | Moisture Resistance | Oiling Requirement | Cost |

| Metal | Very High (Over 100 cycles) | Very Smooth and Polished | High | Yes | High |

| Wood & Plywood | Medium (Fewer than Metal) | Creation of Natural Textures | Low (Sensitive to Moisture) | Yes | Medium to High |

| Plastic | High (Up to 50 cycles) | Smooth and Uniform | Very High | No | Cost-Effective |

| Paper | Low (Disposable) | Creation of Delicate Designs | Low | No | Low |

Specialized Formwork and Scaffolding Systems

In this section, we conduct a specialized review of vital tools in the construction industry. Formwork and scaffolding are not just recognized as supporting tools; they are fundamental components that guarantee the final quality and safety of a project. From advanced modular systems for increased speed and accuracy to specialized forms for curved structures and heavy slabs, each of these systems plays a vital role in realizing architectural and engineering designs. This section helps you become familiar with the types of these systems, their applications, and advantages, allowing you to make the best choice for your projects.

Modular Formwork Systems

Modular formwork systems are modern and standardized solutions in the construction industry that allow for the rapid assembly and disassembly of prefabricated elements. Due to their standardization, these systems increase speed and accuracy in concrete projects.

Wall and Column Formwork

Wall and column formwork play a critical role in shaping the main structure of a building. For tall walls, one-sided wall formwork and two-sided wall formwork are used, which withstand the lateral pressure of fresh concrete. For curved and circular structures, such as silos and tanks, curved wall formwork can be utilized. While arch forms are more suitable for large radii, using modular forms with narrower widths (e.g., 30 or 50 cm) is also possible for complex curves, although this requires greater executive skill.

Furthermore, special formworks are used to shape columns, produced in various shapes such as rectangular column formwork, square column formwork, and circular column formwork. Among these, the ZEMAX variable column formwork system is an innovative and comprehensive solution from ZAMAN Company. Instead of using many small panels, this system consists of four large panels (large panels) that are slidingly adjustable, quickly changing the column cross-section dimensions without the need for complete dismantling.

ZEMAX Variable Column Formwork

This evolution shifts the execution paradigm from an approach based on managing individual components to an integrated and intelligent system, minimizing logistical challenges and the risk of component loss by reducing the number of parts. This approach not only increases efficiency on the job site but also represents a modern operational strategy that goes beyond mere product sales to offer a complete solution for project management problems.

In the execution of concrete structures, especially in exposed facades, familiarity with details and column formwork calculation plays a significant role in the final accuracy and quality of the work.

Slab and Special Structure Formwork

In the slab formwork section, the ECO slab formwork is introduced as a sustainable alternative to polystyrene (Styrofoam) and clay blocks. Due to their very light weight, reusability (up to 50 times), moisture resistance, and lack of need for oiling, these wood-plastic forms drastically reduce costs and execution time. Their use eliminates the risk of foam fires and the emission of toxic gases, and reduces the dead load of the building.

Tunnel formwork is an industrial and advanced system for the rapid construction of concrete frames in mass and high-rise projects. This system creates a monolithic, box-shaped structure by simultaneously concreting walls and slabs, which has much higher seismic and thermal resistance compared to steel structures. Tunnel forms significantly reduce the overall time and cost of the project by reducing the need for labor and eliminating some finishing operations.

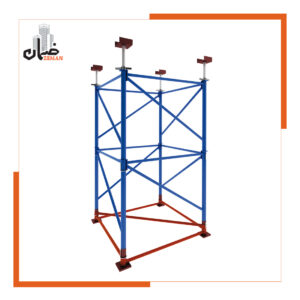

Scaffolding Systems

Scaffolding systems in concrete projects are used to provide safe access and support for the structure during various stages. The choice of scaffolding type is a balance between flexibility, speed, and safety.

Traditional Scaffolding: This non-modular system, consisting of separate pipes and couplers, is used in projects with complex geometries, such as scaffolding around mosque domes or historical buildings, due to its unparalleled flexibility. The safety of this system heavily depends on the skill and experience of the scaffolding master.

Modular Scaffolds:

- H-Frame Scaffolding: This modular system consists of H-shaped frames and is suitable for small and medium-sized projects like cladding and plastering due to its simplicity, easy assembly/disassembly, and cost-effectiveness.

- Cuplock and Cuplock Scaffolding: These systems (also known as cup-and-saucer scaffolding) are installed with simple hammer taps and have very high execution speed. Due to their high load-bearing capacity, they are used for heavy slab shoring, bridge construction, and high-rise structures.

The difference in these systems indicates a significant evolution in the construction industry: a shift from traditional methods based on individual skill to standardized, safe, and predictable systems. While Omega Triangular Scaffolding and Service Scaffolding also exist, these systems significantly increase worker productivity and safety by providing quick and easy access. The choice between these systems depends on the nature of the project (complex or simple) and economic goals (speed or flexibility). Ultimately, the **price and purchase of scaffolding** are determined based on its type, material, and weight.

Comparison Table of Scaffolding System Types

| Scaffold Type | Erection Speed | Load Capacity | Flexibility | Primary Application | Skill Requirement |

| Traditional | Slow | Medium | Very High (For Complex Shapes) | Historical Buildings and Complex Geometries | Very High (Skill Dependent) |

| H-Frame | Fast and Simple | Medium | Medium | Cladding, Plastering, Small and Medium Projects | Low |

| Cuplock & Ringlock | Very Fast (with hammer) | High | High | Slab Shoring, Bridge Building, High-Rise Structures | Low |

| Triangular (Shoring) | Easy | Very High | Medium | Heavy Slab Shoring and Bridges | Medium |

Support Jacks and Formwork Connections: The Backbone of Safety

In any construction project, structural stability and worker safety are paramount. Support jacks and formwork connections play the role of the backbone of a robust formwork system. These tools withstand the massive pressure of fresh concrete, prevent form deformation, and ensure the final structure takes shape with the required precision and quality. This section reviews various types of ceiling jacks and plumbing props, as well as critical connections that, alongside formwork, create an integrated and safe system for concrete projects.

Ceiling Jacks and Their Types

Ceiling jacks are temporary support devices used to bear the load of the concrete slab or roof until the concrete reaches sufficient strength. Concrete generally requires about 7 to 14 days to achieve the necessary strength, after which the jacks can be removed. Selecting the appropriate jack is a critical safety calculation. Substandard jacks can lead to structural failure, so they must be chosen based on load, height, and structure type.

Purchase of Simple Ceiling Jack: These jacks have a flat plate at the top and are used to support joists, columns, and one-sided walls.

Purchase of Simple Ceiling Jack

U-Shaped Jack (Iraqi Jack): This type of jack has a U-shaped groove at the top, making it ideal for supporting H20 wooden beams or metal joists. They are made of steel due to their high load-bearing capacity and durability.

Purchase of U-Shaped Ceiling Jack and Purchase of U Head: These jacks are designed to be used under beams and girders, where by placing two scaffolding pipes in two column directions and placing a cross jack underneath, the structure can be leveled.

Plumbing and Wall Support Jacks

Plumbing jacks (or wall and column support jacks) are specifically used to hold wall and column forms in place and ensure they are vertical (plumb) during concrete pouring. These jacks counteract the massive lateral pressure of fresh concrete, preventing form deformation and deviation. These jacks are produced in two main types:

- Single Arm: For lateral support of wall forms.

- Double Arm: Used to prevent the deviation of the system in taller structures and to withstand higher loads.

For information on the price of wall backing jacks and purchasing plumbing jacks, one can refer to reputable manufacturers.

Formwork Connections

Connections are small components that hold the entire formwork system together and play a vital role in its stability and safety.

Pin and Wedge: These tools are used to connect concrete formwork panels to each other. Approximately 8 pairs of pins and wedges are needed per square meter of formwork.

Wing Nut and Washer: The wing nut is used to connect the washer to the backing structure, and the cup washer prevents localized crushing by distributing the force.

Medium and Long Clamps: These clamps are used to connect horizontal pipes and backing structures to the formwork panels to increase their resistance against the lateral pressure of the concrete.

In summary, the precise selection of jacks and formwork connections is as important as the selection of the formwork itself and forms the backbone of safety and quality for a concrete project.

Comparison Table of Support Jack Types

| Jack Type | Primary Application | Load Capacity | Adjustment Mechanism | Key Advantage |

| Simple Ceiling | Slab support, joist bracing, column plumbing | Medium | Screw and Nut (Manual) | Simplicity and reasonable price |

| U-Shaped Ceiling | Support for metal joists and H20 beams | High | Screw and Nut | More optimal load transfer via U-shape surface |

| Plumbing Prop | Maintaining the plumb of wall and column forms | High (Up to 1500 kg) | Left-hand and Right-hand Screws | Counteracting lateral pressure of concrete and increasing stability |

Execution Stages and Maintenance

The successful execution of an exposed concrete project is inextricably linked not only to the selection of appropriate formwork but also to accuracy in execution stages and maintenance. In this section, key points from the moment panels are installed to the final protection of the concrete surface are addressed, offering practical guidance for achieving the best possible result. From modern installation methods like dry and mortar application to the critical importance of waterproofing and precise stripping timing, every stage plays a decisive role in the durability and aesthetics of the project.

Installation Methods for Exposed Concrete Panels

Exposed concrete panels are installed using two main methods, each having its own advantages and requirements:

Dry Fixing

This method is performed using mechanical fittings such as screws, welding, and brackets. Dry fixing is very fast and offers high resistance against natural elements like storms and rain. In this method, the panels are drilled from the back and attached to the facade’s metal frame by screws or welding.

Mortar Fixing

This method, similar to natural stone installation, is done using cementitious grout. Mortar fixing is generally used for flooring, with a grout thickness of at least 3 cm. After installation, joint sealing with waterproofing materials is essential to prevent water penetration.

Waterproofing and Surface Protection

Concrete is inherently a porous material and, without protection, is susceptible to moisture absorption, staining, and efflorescence. This can diminish the aesthetics and durability of exposed concrete over time. To counter this problem, waterproofing materials and nano-coatings are used. Powdered and liquid water-repellents prevent water penetration by filling the empty spaces within the concrete, making it hydrophobic.

Nano-coating solutions utilize nanotechnology to penetrate deep into the concrete, creating an invisible protective layer that, in addition to preventing water absorption, inhibits the growth of fungus, efflorescence, and moss, and makes the surface self-cleaning. These layers increase the concrete’s resistance to freezing and UV radiation without altering its appearance.

Important Notes on Form Stripping (Demolding)

The timing of concrete form stripping is a sensitive and critical stage that can cause irreparable damage to the structure if done prematurely. The concrete must have achieved the minimum required strength to withstand the stress caused by form removal. Ambient temperature plays an important role in the concrete’s setting time; in cold or freezing weather, the time required for stripping increases. Therefore, close monitoring of the concrete curing process and adherence to time standards are essential to ensure the structural health and stability.

Economic Factors and Exposed Concrete Formwork Purchasing Tips

In any construction project, a precise understanding of economic factors and purchasing considerations is as important as technical knowledge. Pricing in the formwork and scaffolding industry is a function of numerous variables that directly affect the final project costs. From daily fluctuations in steel prices to the quality of raw materials and production technology, each of these factors can influence the decisions of contractors and investors. This section helps you become familiar with the key factors affecting price and make the smartest choice for your projects by considering aspects such as equipment purchase versus rental.

Factors Affecting Price

The price of wall backing jacks, H20 wooden beam purchase, plywood formwork purchase, and other formwork equipment depends on various factors. The quality of the sheet metal and raw materials is the most important factor in determining the price. Using high-quality steel sheets, such as ST37, increases the final price but guarantees the formwork’s resistance and service life. Production technology, especially the type of welding (such as CO2 welding), as well as the weight and dimensions of the product, also influence the final price.

Cost Estimation: From Materials to Installation Labor

The final cost of an exposed concrete project depends on numerous factors, including panel dimensions, material type and quality, and installation labor costs. The cost of installing exposed concrete panels per square meter varies depending on the execution method and the complexity of the design. For example, in some cases, the cost of dry fixing is higher due to the use of special fittings and hardware, but the high speed of execution can compensate for this cost. Furthermore, market prices (such as Cuplock scaffolding price or plank price) fluctuate daily based on changes in steel and other raw material costs.

Buying Guide

When purchasing scaffolding planks, triangular shoring, or other equipment, an important decision is choosing between buying new or second-hand equipment. For short-term projects, renting or buying used equipment can be cost-effective. However, for long-term projects or construction companies with high workloads, purchasing new equipment from a reputable manufacturer like ZAMAN, which produces its products according to the highest quality standards, is considered a long-term investment.

Purchase of Triangular Shoring

Conclusion

Success in executing exposed concrete projects is inextricably linked to the quality of formwork and supporting systems. Formwork in this process is not a simple tool but part of the design process and a vital factor for achieving the desired final result. From purchasing U-Head jacks and U-shaped ceiling jacks to Cuplock scaffolding and precast concrete element formwork, every piece plays a key role in the safety, speed, and accuracy of the project.

Given the technical complexities and economic considerations, collaboration with a company that offers comprehensive and innovative solutions is a necessity. ZAMAN Company, by providing a full range of modern formwork and scaffolding systems such as the ZEMAX variable column formwork and ECO slab formwork, has established itself as a strategic partner for construction industry professionals. The company’s products help contractors and architects transform their creative ideas into stable, safe, and beautiful structures with full confidence by improving efficiency, reducing execution complexities, and guaranteeing final quality.

Frequently Asked Questions

What are the constituent materials of exposed concrete?

Exposed concrete is made of materials such as Portland cement, specially graded aggregates, pozzolans (like microsilica), pigments, mineral and chemical admixtures, and fibers.

In what dimensions are exposed concrete panels manufactured?

Exposed concrete panels are manufactured in various sizes and dimensions. Common dimensions include 60×120, 50×50, 50×90, and 30×60 cm, but custom sizes can also be produced.

How do we protect exposed concrete from weather conditions?

Exposed concrete must be made hydrophobic using waterproofing agents and nano-coatings to resist weather conditions and moisture. These materials penetrate the depth of the concrete, preventing water absorption and efflorescence.

What is the service life of exposed concrete?

The service life of exposed concrete tiles is generally between 70 and 90 years, and they have high resistance to natural factors and impact.

What is the main difference between cast-in-place and precast exposed concrete?

Cast-in-place exposed concrete is poured on-site, while the precast type is manufactured as panels in a factory and then installed. The precast type has higher quality and strength due to production in a controlled environment.

Can exposed concrete be repaired?

Yes, one of the advantages of exposed concrete is its ease of repair and renovation, especially when used as ready-made panels that are easily replaceable.

What are the main advantages and disadvantages of using exposed concrete?

- Advantages: High durability and resistance, thermal and acoustic insulation, high execution speed, design diversity, and easy maintenance.

- Disadvantages: The cold and stark nature of concrete (which can be compensated for with various colors), porosity (which requires periodic waterproofing), and sensitivity to environmental conditions.

Is the use of exposed concrete formwork cost-effective?

Exposed concrete forms are cost-effective in the long run due to their high reusability. While their initial cost may be high, they reduce the final project cost compared to materials like stone and composite panels.

When should concrete forms be stripped?

The timing for stripping forms depends on the type of structure and ambient temperature. Generally, stripping should occur when the concrete has reached sufficient strength to prevent structural damage. For example, column and wall forms can be removed after 24 to 48 hours, and slab forms after 7 to 14 days.

What is the application of a plumbing jack?

The plumbing jack is used for stabilizing and holding wall and column forms in place during concrete pouring and counteracting the lateral pressure of the concrete. These jacks help ensure the structure is vertical.

Is hammer-set scaffolding better or Cuplock scaffolding?

Both hammer-set and Cuplock scaffolding are modular systems with high installation speeds. Hammer-set scaffolding (star-shaped) has higher strength due to more secure connections and is suitable for heavier projects like bridges, while Cuplock scaffolding is widely used for heavy slab shoring and building facades.

What is the advantage of the ZEMAX variable column formwork?

The ZEMAX system consists of four large panels that are slidingly adjustable. This feature eliminates the need to change and manage numerous small parts, drastically increases execution speed, and reduces logistical complexities.