Triangular Scaffold

When it comes to supporting heavy concrete slabs, bridge decks, and massive structures, there is no room for conventional solutions. Triangular scaffolding, as the most advanced evolution of load‑bearing scaffold systems, provides a decisive answer to engineers’ demands for higher load capacity, enhanced safety, and faster execution speed. This system, regarded as the next generation of traditional triangular scaffolding, is manufactured by Zaman Company in accordance with the highest standards to ensure complete confidence in the stability of your structure.

Metal scaffolding systems are available in various types, one of which is triangular shoring scaffolding. This type of scaffold is also known by other names such as triangular scaffold, shoring scaffold, or simply scaffolding. Shoring scaffolds are commonly used in different parts of buildings for formwork support and slab execution. Selecting this type of scaffold for heavy structures can be an excellent engineering choice. One of the key pillars of concrete structure construction is the careful and high‑quality selection of shoring scaffolding systems that provide maximum stability and exceptional load‑bearing performance.

Triangular Scaffold

What Is Triangular Scaffold (Triangular Shoring Scaffolding)?

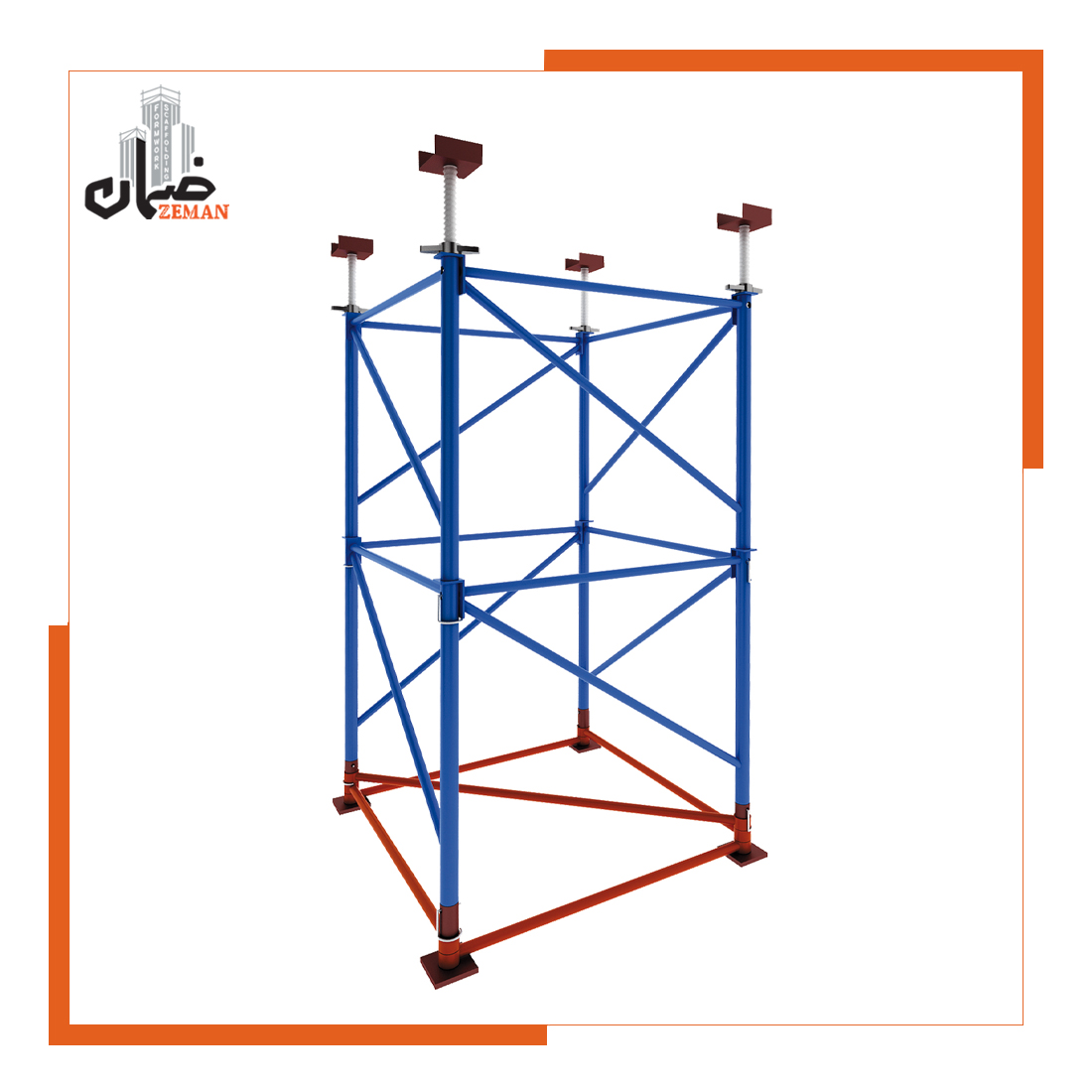

Triangular scaffold is also known as shoring scaffolding or triangular shoring. This system is manufactured from triangular‑shaped sections which form square‑like frames with a side length of 120 cm. Triangular scaffolding is assembled using base plates, horizontal and diagonal braces, adjustable jacks, and screw adjusters. Height adjustment of the scaffold is carried out by means of the screw jacks.

This type of scaffolding is primarily used for shoring heavy and high concrete structures such as vehicle bridges and solid concrete slabs. In addition, it may also be used as an access scaffold for work at height, in which case the bearing capacity and stability of the ground beneath the scaffold must be carefully considered. Compared to other scaffolding systems, triangular scaffolding can be installed much faster and does not require highly skilled labor. Moreover, its installation requires fewer workers.

What Is Shoring Scaffolding?

Scaffolding is generally used as a temporary structure in construction projects, mainly to create work platforms and provide access to elevated areas. Scaffolding is also used as shoring or back support in formwork systems. Shoring scaffolding is one type of scaffolding specifically designed for supporting heavy and large concrete projects. Shoring scaffolding is constructed by assembling triangular frames, which is why it is also referred to as triangular shoring. When properly installed and executed, shoring scaffolding offers a high point load capacity and can withstand loads of up to 13 tons per square meter.

Metal scaffolding is available in various types, one of which is triangular shoring scaffolding. This system is also known by other names such as triangular scaffold, scaffold, or shoring scaffold. Shoring scaffolding is commonly used in building sections for slab formwork and roof execution. Choosing this type of scaffold for heavy structures can be an excellent solution. One of the most critical factors in concrete structure construction is the accurate and high‑quality selection of scaffolding systems that provide maximum stability and load‑bearing capacity.

In general, triangular scaffolding is used as a temporary structure in large‑scale projects. The arrangement of scaffolding components directly affects load distribution and the overall weight‑bearing capacity of the structure. Shoring scaffolding consists of four main components that are connected through male‑and‑female joints. Their primary function is to maintain the structural geometry until the concrete has fully cured. The installation of this type of scaffolding does not require skilled labor, and with adequate knowledge of the installation process, it can be erected efficiently.

What Components Does Shoring Scaffolding Include?

Understanding the components of shoring scaffolding helps you make informed purchasing decisions and prevents potential financial and safety risks. Shoring scaffold frames are manufactured in heights of 50, 75, and 100 cm, with a constant width of 120 cm. The steel tubes used in these frames must be seamless, as welded (seamed) pipes have lower load‑bearing capacity and may collapse under heavy loads. Other components of shoring scaffolding include:

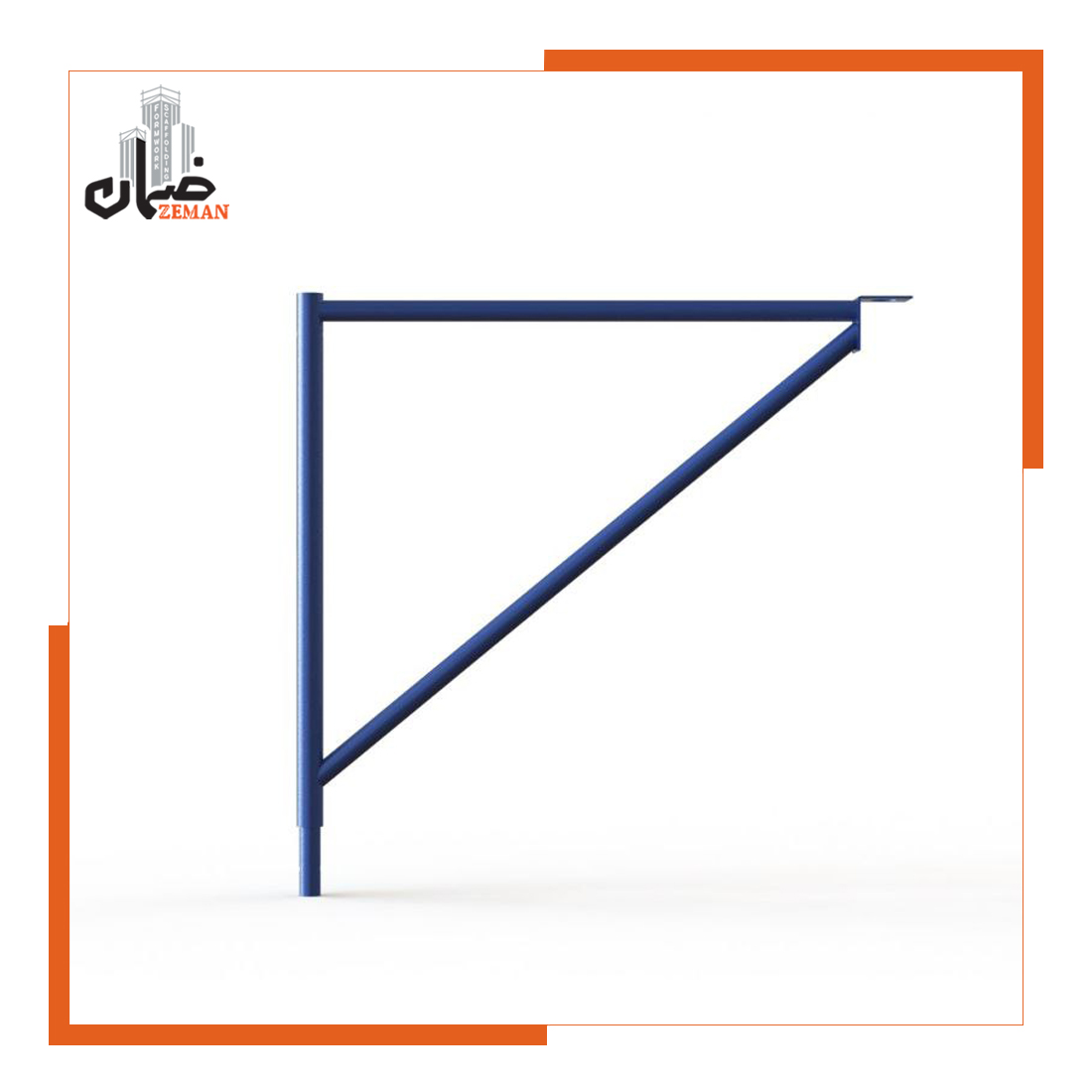

- Horizontal braces

- Diagonal braces

- Adjustable head jack

- Screw adjuster

- Base plate (foot plate)

| Component Type | Dimensions (cm) | Weight (kg) |

|---|---|---|

| Triangular Scaffold Frame | 120 × 50 | 8 |

| 120 × 75 | 9 | |

| 120 × 100 | 11 | |

| Horizontal Brace | 120 | 4.5 |

| Diagonal Brace | 170 | 5 |

| Base Plate | 14 | 1.5 |

How to Assemble Triangular Scaffolding

Correct installation of triangular scaffolding is critical, as any mistake may compromise worker safety. The assembly process is as follows:

Step One: Site Preparation

The ground surface on which the scaffold will be installed must be completely level and firm. If the ground is uneven, steel base plates are used to ensure proper leveling.

Step Two: Assembly of Triangular Frames

The prefabricated triangular metal frames are positioned next to each other. These frames are typically made of high‑strength steel to ensure adequate structural integrity.

Step Three: Connecting the Frames

The triangular frames are connected using pins and spigots, forming a rigid structural system. At this stage, careful inspection of all connections is essential.

Step Four: Installing Adjustable Base Jacks

Adjustable base jacks are installed at the lowest level of the scaffold to regulate the overall height and ensure stability. These components play a vital role in evenly distributing loads and increasing system stability.

Final Step: Inspection and Safety Check

After completion, all scaffold components should be inspected to verify proper connections and structural balance. The use of safety equipment such as personal fall protection systems is also mandatory.

Formwork Installation Using Triangular Scaffolding

Prior to execution, the layout of triangular scaffolding is determined based on structural drawings. Depending on the thickness of the concrete slab, the spacing between scaffold towers is specified. The greater the slab thickness, the smaller the spacing between scaffold towers. Using triangular scaffolding, slab concreting can be performed with either plywood sheets or steel formwork panels. The triangular frames can be easily assembled without requiring additional connectors. Heavy tools and specialized equipment are not needed for installation, making this system highly effective for formwork in non‑level intersections and complex structures.

Advantages of Triangular Frame Scaffolding

- Applicable to various types of structures

- Modular structural design

- Adjustable spacing to accommodate different concrete thicknesses

- High execution speed

- An effective replacement for non‑standard and excessively tall slab props

- Assembly without the need for additional connectors

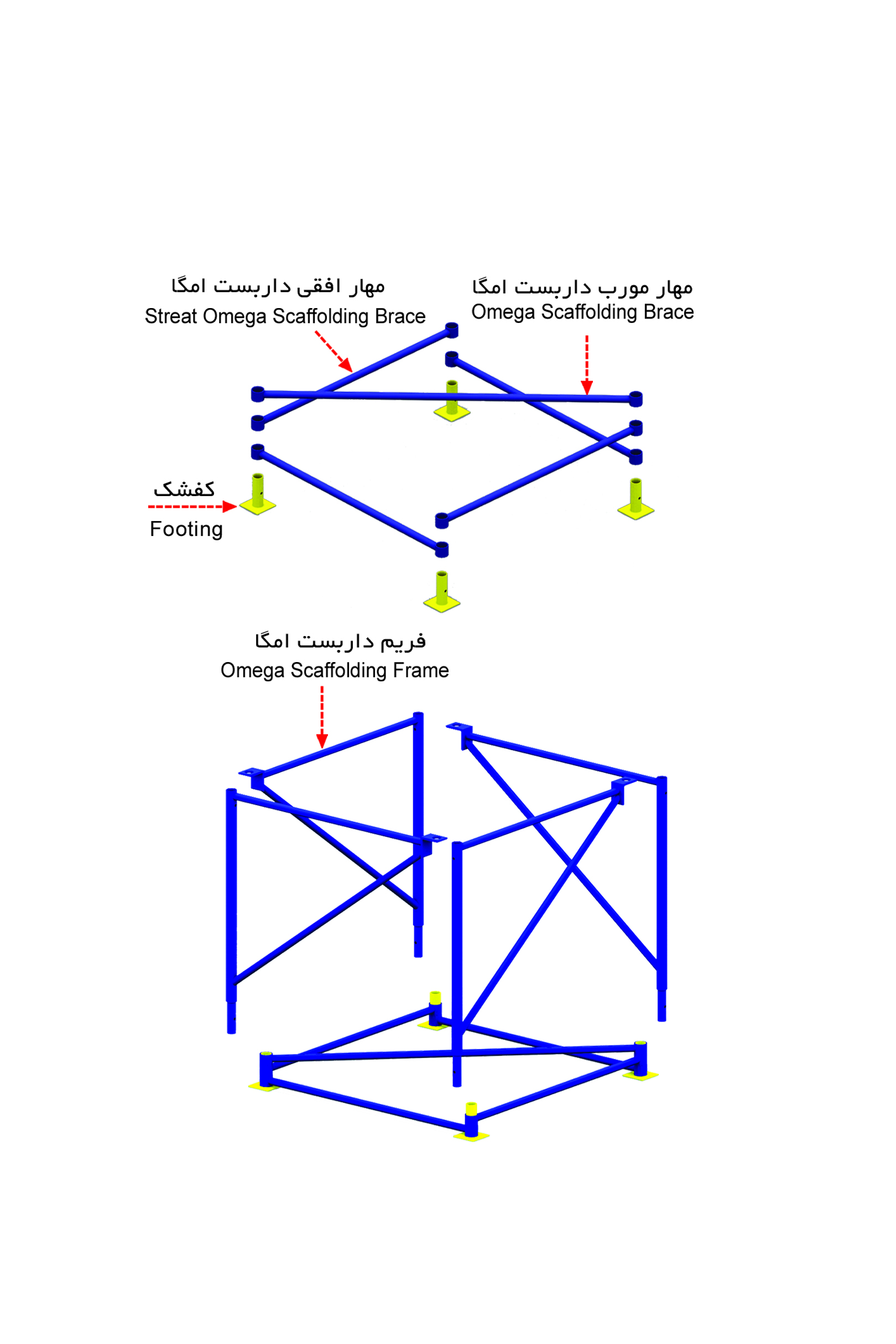

What Is Omega Triangular Scaffolding and How Does It Differ from Standard Triangular Scaffolding?

Omega scaffolding is widely used in construction projects for safe and reliable slab formwork. It is one of the most commonly applied formwork systems, particularly suitable for shoring heights exceeding four meters. Omega scaffolding is also known as triangular scaffold, shoring scaffold, or triangular frame system, and it enables slab formwork at virtually any height. Its male‑and‑female connection system allows fast installation without special tools.

Standard triangular scaffolding has long been regarded as a reliable solution for formwork. However, Omega scaffolding enhances this system through several key, engineered improvements:

- Higher load‑bearing capacity: Omega scaffold frames are manufactured from thicker steel tubes (typically 3 mm), with optimized joint design, allowing heavier vertical loads per square meter.

- Faster and safer locking system: The Omega pins are designed for quick and secure locking, increasing assembly speed while significantly reducing human error.

- Improved lateral stability: Optimized frame geometry and horizontal and diagonal bracing enhance overall stiffness and resistance to lateral forces.

In summary, Omega scaffolding offers the same simplicity and practicality of traditional triangular scaffolding, but with greater strength and faster execution. Its key features include:

- Fast and simple connection without special tools

- Lightweight and portable, ideal for concrete slab formwork projects

- Manufactured in heights of 50, 75, and 100 cm with flexible adjustment capability

- High load‑bearing capacity and structural rigidity for heavy‑duty applications

- Simple installation with fewer components and rapid assembly and dismantling

- Suitable for slabs, beams, and tall structural elements

- High flexibility in scaffold layout and height configuration

Specialized Applications: Where Should Omega Scaffolding Be Used?

- Bridge deck formwork: Designed to support extremely heavy concrete loads and construction equipment.

- High and thick slabs: Such as shopping centers, multi‑storey parking structures, and industrial halls.

- Special and heavy structures: Ideal for projects with high concentrated loads.

- Economical replacement for slab props: Where conventional slab props are insufficient or unsafe.

Learn More About Triangular Modular Scaffold (Omega Triangular Scaffolding)

Triangular modular scaffolding is created by interconnecting triangular elements. These elements are easily assembled without the need for special tools or skilled labor, resulting in a lightweight yet strong scaffolding system. Due to its light components, ease of installation, and high load capacity, this system is widely used for the execution of various concrete slabs. In any structure where a load‑bearing surface is required at significant height for formwork, the use of triangular scaffolding is recommended from both technical and economic perspectives.

Triangular scaffold elements are produced in heights of 50, 75, and 100 cm, allowing the system to be applied at any desired elevation. Based on plan geometry, these elements can be connected in square or triangular configurations to achieve different load capacities. In slab and beam formwork, as well as in heavy concrete structures with thick and elevated slabs, the use of triangular scaffolding is essential due to the substantial loads involved.

The use of modular scaffolding systems greatly facilitates execution. These systems consist of a limited number of lightweight components that can be quickly and easily connected. Owing to their structural form, they offer high rigidity, superior load‑bearing capacity, and easy height adjustment. Dismantling of components is also fast and straightforward.

Technical Specifications and Comparison Table

| Technical Specification | Omega Triangular Scaffolding (Recommended) | Standard Triangular Scaffolding |

|---|---|---|

| Load capacity per leg | Very high (up to 8 tons) | High (up to 5 tons) |

| Frame tube thickness | 3 mm (heavy‑duty) | 2.5 mm (standard) |

| Assembly speed | Very high | High |

| Connection safety | Very high (Omega pin) | High |

| Primary application | Bridge construction, ultra‑heavy slabs | Standard formwork shoring |

Step‑by‑Step Guide to Installing Omega Triangular Scaffolding

- Ground preparation and leveling: Position the base plates (adjustable jack bases) on a firm and level surface.

- Installing the first frame row: Place the first row of Omega frames onto the base plates.

- Bracing connection: Connect the frames using horizontal and diagonal braces to create a stable grid.

- Height extension: Install subsequent frames vertically using Omega pins.

- Repeat bracing: Perform bracing at each level.

- Installing head jacks: At the top level, place adjustable U‑Head jacks to support beams and slab profiles.

Frequently Asked Questions (FAQ)

Can Omega scaffolding components be combined with standard triangular scaffolding?

No. Due to differences in precise dimensions and pin systems, mixing these two systems is strongly discouraged in order to maintain structural safety and integrity.

How does the price of Omega scaffolding compare to the standard type?

Because of the increased material usage and greater tube thickness, the initial cost of Omega scaffolding is slightly higher. However, this additional cost is offset by faster execution, reduced labor requirements, and enhanced safety, resulting in a lower overall project cost.

Why Is Zaman the Best Choice for Purchasing Omega Scaffolding?

At Zaman, we are not merely a supplier—we are your partner in executing safe and successful construction projects.

- Quality assurance: We manufacture Omega triangular scaffolding using true 3 mm thickness steel and CO₂ welding.

- Free technical consultation: Our engineering team carefully analyzes your project and provides optimal solutions with precise calculations.

- Direct factory sales: By eliminating intermediaries, we guarantee the most competitive pricing.

- For technical catalogs, expert consultation, and instant pricing, contact us today at

09128441055.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.