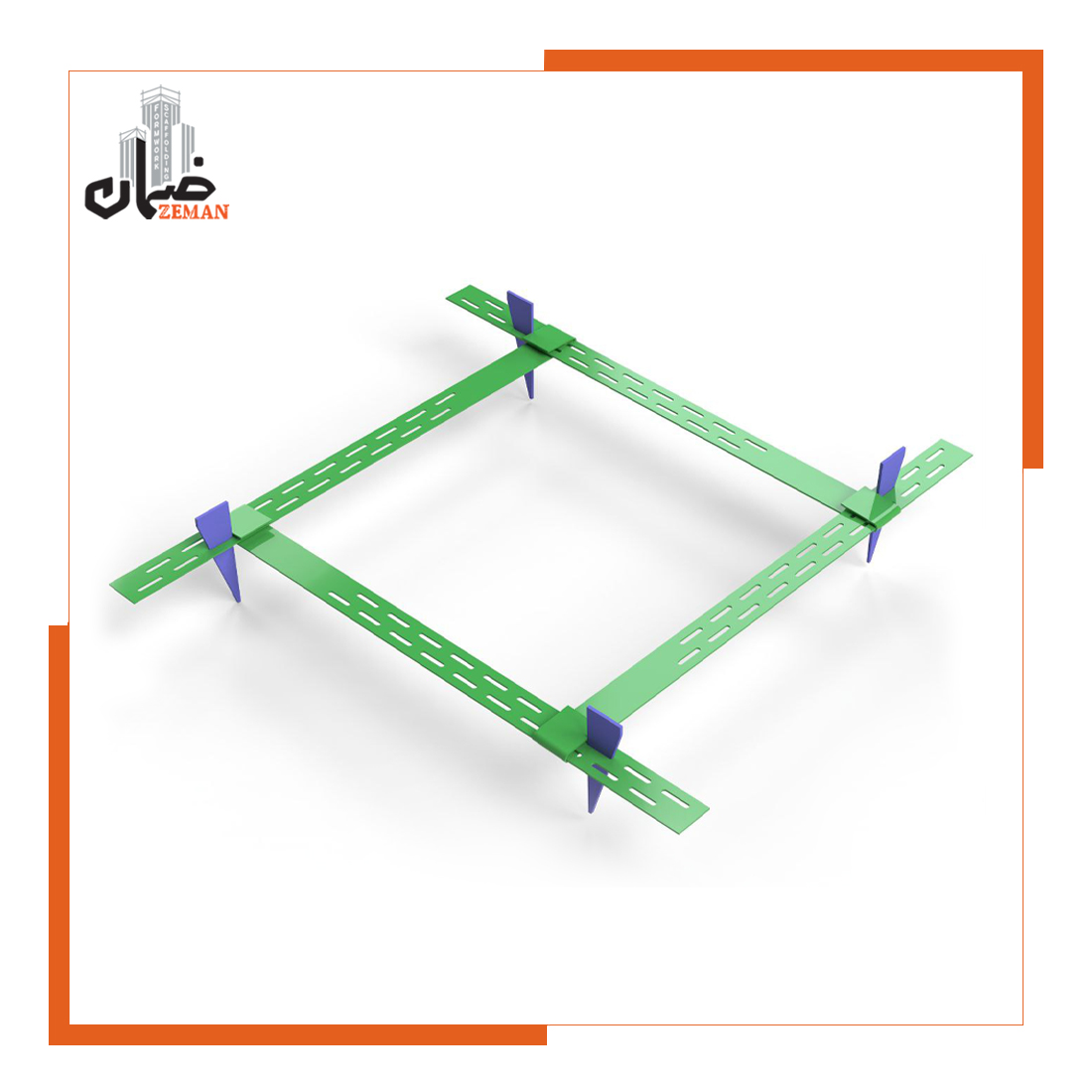

Strap-Type Corner Brace

The strap-type corner brace is one of the most commonly used components in concrete formwork equipment, designed for bracing formwork panels and stabilizing their vertical alignment and angular positioning.

This component plays a crucial role in enhancing the accuracy, strength, and stability of formwork—especially in systems utilizing wooden boards—during the concrete pouring process. The strap-type corner brace is a metal component manufactured from steel plate with an 8 mm thickness and is used to form precise 90-degree angles, or angles very close to it, between formwork elements.

Applications of the Strap-Type Corner Brace in Concrete Formwork

- Stabilizing formwork corners in concrete columns

- Maintaining exact right angles (squareness) between perpendicular formwork panels and increasing the resistance of the formwork against the lateral pressure of fresh concrete, which is the primary function of this product.

Advantages of Using the Strap-Type Corner Brace

- Ensuring precise squareness between formwork surfaces

- Preventing formwork opening or bending at intersection points

- Fast and easy installation

- Improving the final quality of the concrete structure in terms of form accuracy and angular precision

Strap-Type Corner Brace

Introduction: Engineering Precision in Concrete Structures with Zeman Connections

In the construction and civil engineering industry, where structural strength and stability are paramount, precision in execution details defines the difference between a successful project and a hazardous structure. Zeman, as one of the leading manufacturers of concrete formwork equipment in the Middle East, has recognized this critical need and developed a comprehensive range of formwork connectors and accessories, each playing a vital role in ensuring the final quality of concrete structures.

Among these challenges, the execution of concrete columns with perfectly square angles (90 degrees) is one of the most demanding and critical stages of construction. Any deviation or “twisting” in a column can disrupt the load distribution throughout the structure and compromise overall safety. To address this challenge, professional engineers and contractors require tools that go beyond standard connections: the strap-type corner brace.

This component, which is recognized as a key element within Zeman’s concrete formwork system, is far more than a simple metal clamp; it is an engineered solution designed to restrain the massive lateral pressures of fresh concrete and to guarantee absolute squareness of column formwork. This article provides a technical analysis of the function, specifications, and correct use of the strap-type corner brace in concrete formwork projects, demonstrating how this seemingly simple connection becomes the backbone of precision and safety on site.

Technical Breakdown of the Zeman Strap-Type Corner Brace: Beyond a Simple Connection

In concrete construction, the quality and performance of a corner brace are defined by its technical details—details that directly affect resistance to the hydrostatic pressure of fresh concrete and durability under demanding site conditions. Zeman products are engineered in accordance with strict design principles and manufactured using premium raw materials to deliver the highest level of reliability for construction professionals.

Material and Manufacturing: The Foundation of Strength and Durability

The core of the strength of the Zeman strap-type corner brace lies in the use of ST37 structural steel plate supplied by Mobarakeh Steel Company. This steel grade, known for its high tensile strength and excellent toughness, is an ideal choice for formwork equipment subjected to extreme stresses.

Unlike common corner braces available on the market, Zeman products are manufactured with engineered thicknesses to resist deformation and bending under heavy loads. The production process utilizes precision machinery and standardized CO₂ welding to ensure an exact 90-degree angle and fully integrated, high-strength welds. This manufacturing accuracy guarantees that the corner brace functions effectively as an external support, maintaining the geometry of the formwork with maximum reliability.

Engineered Design for System Integration

Zeman corner braces are designed for full compatibility with the company’s modular formwork systems, including strap-type (welded) panels and bent-edge panels. This integrated approach allows the braces to be easily installed using other standard Zeman accessories such as medium and long clamps, forming a robust and highly efficient bracing system. This intelligent design eliminates the need for incompatible components or temporary, unsafe site-built solutions.

Specialized Application: Bracing Concrete Columns

The primary and specialized application of the strap-type corner brace is in securing and squaring formwork for square and rectangular concrete columns. When fresh concrete is poured into a column formwork, substantial hydrostatic pressure is exerted on the panels, tending to push them outward and disturb the 90-degree corner angles.

This is where the corner brace performs its critical function:

- Maintaining right angles: By installing corner braces at specified vertical intervals along the column height, a rigid external frame is created around the formwork, preventing joint opening and ensuring that all faces of the column remain perfectly perpendicular.

- Preventing column twisting: In tall columns, uneven concrete placement may cause torsional forces and twisting. The use of corner braces—especially when installed alternately in different directions—effectively controls these forces and maintains vertical alignment.

- Enhancing overall formwork integrity: By linking adjacent panels through horizontal walers (steel tubes or channels), the corner brace contributes to the integrity of the entire formwork assembly, transforming it into a unified, rigid structural box.

Used alongside other components such as pins and wedges, clamps, and tie bolts, the corner brace forms part of a complete system engineered to deliver precise, safe, and high-quality concrete structures.

Installation Guide and Best Practices on Site

Correct and proper installation of the corner brace is essential for optimal performance and full safety of the column formwork system. Although the process is straightforward, strict attention to key installation principles is required.

Required Equipment:

- Zeman modular formwork panels

- External corners

- Pin and wedge

- Zeman strap-type corner brace

- Medium clamp (for tube walers) or long clamp (for channel walers)

- Horizontal walers (scaffold tubes or steel channels)

Step-by-Step Installation Procedure:

- Initial formwork assembly: Assemble the four sides of the column formwork using external corners and secure them with pins and wedges to form the initial column box.

- Installation of horizontal walers: Position the scaffold tubes or steel channels at predetermined vertical intervals (typically every 50 to 75 cm) around the formwork.

- Positioning the corner braces: Place the corner brace at each corner of the formwork, exactly at the intersection points of the horizontal walers. The internal angle of the brace must fully align with the external corner of the formwork.

- Securing with clamps: Using the appropriate clamp (medium or long), simultaneously fasten the corner brace and the waler to the perforated edges of the formwork panels. Repeat this process at all corners and at each bracing level.

- Final inspection: After installing all braces, recheck the plumbness and squareness of the entire assembly and ensure that all connections are securely tightened.

Key Execution Tips:

- Vertical spacing: The vertical distance between rows of corner braces depends on column height and the expected concrete pressure. For taller columns, spacing should be reduced.

- Alternate arrangement: To effectively counteract torsional forces, alternate the orientation of the corner braces at each level.

- Use a complete system: For maximum safety and performance, always use Zeman formwork panels, braces, and clamps as a unified system to prevent incompatibility and weak connections.

What is the difference between a corner brace and other formwork connections such as pins and wedges?

Pins and wedges are used to directly connect two panels on a flat plane. In contrast, a corner brace is an external connection whose primary function is to maintain a 90-degree angle between two perpendicular panels at corners and to restrain the entire assembly against lateral pressures.

Can corner braces be used for wall formwork?

The primary application of corner braces is in column formwork and 90-degree corners. For long, straight walls, horizontal and vertical bracing systems (such as soldiers) and tie bolts are used to resist concrete pressure.

Corner braces are available in tubular and strap-type versions. Which one is more suitable for my project?

Both types perform equally well in maintaining right angles. The choice typically depends on the waler system used on site (tubular or channel-based) and the contractor’s preference. Zeman strap-type corner braces are optimally designed for compatibility with both systems.

Why Choose Zeman Strap-Type Corner Braces? The Professional Choice

In the competitive construction equipment market, choosing Zeman products represents a smart investment in quality, safety, and efficiency.

- High-quality raw materials: A commitment to using standard ST37 steel ensures long service life and high resistance under load.

- Manufacturing precision: Engineered production and strict quality control guarantee flawless performance even in the harshest site conditions.

- Integrated system design: Full compatibility with other Zeman formwork components simplifies installation, accelerates execution, and maximizes safety.

- Improved productivity: By eliminating time-consuming, improvised methods for squaring column formwork, Zeman corner braces directly reduce labor costs and increase project execution speed.

For the execution of precise, strong, and safe concrete columns, trust in engineering details. The Zeman strap-type corner brace is a small component with a significant impact on the success of your project. For expert consultation and order placement, please contact our technical specialists.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.