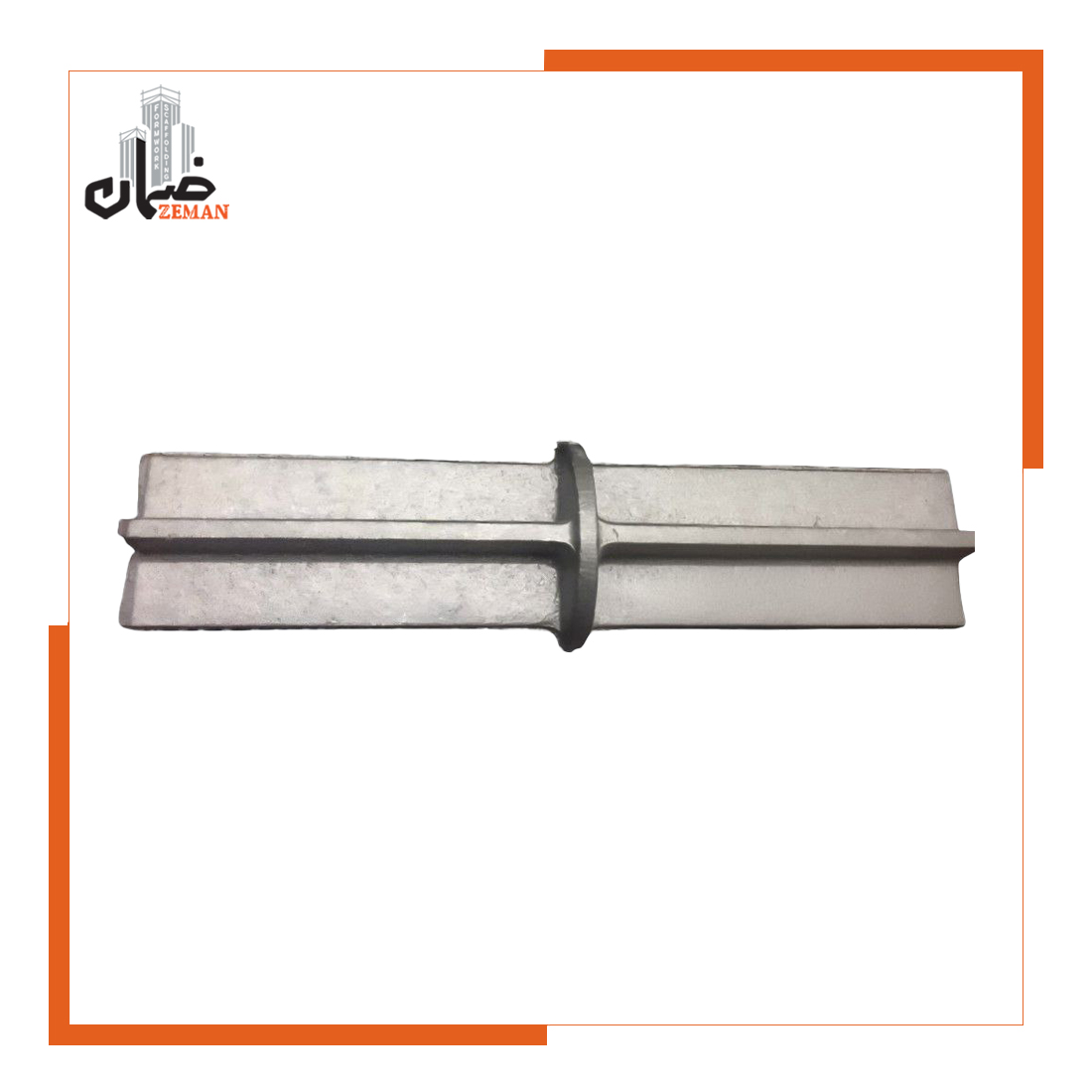

Scaffolding Spigot Pin

The traditional scaffolding spigot pin is a metal component installed inside scaffold tubes, designed to provide a firm and secure connection between two tubes. Manufactured from ductile cast iron or high-quality steel, this component significantly enhances the structural strength and stability of the scaffold against various stresses and heavy loads, particularly at elevated heights. By using a spigot pin, the tubes function as a single integrated unit, thereby ensuring maximum safety for both workers and the overall project.

Scaffolding Spigot Pin

What Is a Scaffolding Spigot Pin and Why Is It Critical?

The scaffolding spigot pin, often referred to as a “scaffold pin” or “internal joint connector,” is one of the most essential and fundamental components of traditional scaffolding systems. This metal component is inserted inside scaffold tubes and serves the primary function of connecting two tubes together, forming a continuous structural element. Although this function may appear simple, it represents the cornerstone of overall scaffold stability and safety. Without a strong internal connector, scaffold tubes can easily separate or deform under applied loads, leading to bending or structural failure.

The role of the scaffolding spigot extends far beyond that of a simple connector. By transferring axial forces between scaffold tubes, it enables them to act as a single, integrated member. This continuity significantly increases the structural resistance against various stresses, particularly bending and torsional forces, and effectively prevents unwanted movement. For this reason, the scaffolding spigot pin is recognized as a key element in modern construction engineering, and its use across building projects is considered indispensable for ensuring structural integrity.

Common Terminology and Alternative Names

In the Iranian construction industry, multiple terms are used for this practical component, which can sometimes lead to confusion among new users or even professionals in different regions. Common names include “scaffold tube spigot,” “scaffolding tube pin,” “scaffold pin,” and “Spigot Joint Pin.”

This variety of terminology reflects the importance and widespread use of this component in different applications and technical cultures. A clear understanding of these terms helps customers accurately identify the required product during the search and procurement process. For example, in some references, the term “scaffold tube pin” is used interchangeably with “spigot,” and its applications in ringlock or hammer-type scaffolding systems are also discussed.

Specialized Applications of Scaffolding Spigot Pins

Scaffolding spigot pins become indispensable, especially in situations where safety and structural strength are top priorities. The most important applications include:

- Heavy-duty and high-rise projects: Spigot pins are highly suitable for scaffolding systems subject to high working loads or heights exceeding 6 meters. This is due to their ability to significantly enhance stability and resistance against heavy loads and wind forces.

- Installation of scaffold formwork (shoring): Spigot pins are used in the installation of scaffold formwork, both inside and on scaffold tubes, demonstrating their versatility and efficiency in different structural sections.

- Under-slab and monumental structures: This component is widely used in under-concrete support systems and structures such as ceremonial arches, highlighting its strong performance under axial and compressive loads. The use of spigot pins significantly increases the strength of scaffold bases and the overall system.

Technical Breakdown of Scaffolding Spigot Pins – From Material to Dimensions

Scaffolding spigot pins are generally manufactured from two primary materials: ductile cast iron (nodular cast iron) and high-quality steel. Each material possesses distinct mechanical properties that make it suitable for specific applications.

- Steel: Steel, due to its uniform crystalline structure and lower carbon content (typically below 2%), offers high tensile strength, excellent toughness, and superior ductility. These properties make steel ideal for applications where the structure is subjected to tensile and bending stresses. Moreover, steel—especially galvanized steel—exhibits enhanced corrosion resistance, significantly extending the service life of the product. However, steel manufacturing processes are generally more complex and costly compared to cast iron.

- Ductile Cast Iron: Ductile cast iron is a type of cast iron in which the graphite structure is modified into spherical nodules, significantly reducing the inherent brittleness of conventional cast iron and improving impact resistance. With a higher carbon content (above 2%), molten ductile iron has excellent fluidity, making the casting process easier and enabling the production of complex shapes. While ductile cast iron offers compressive strength comparable to steel, its tensile strength is lower. Additionally, its production cost is generally lower than that of steel.

Dimensional and Weight Specifications of Traditional Scaffolding Spigot Pins

Dimensions and weight are critical indicators that directly affect the quality and performance of scaffolding spigot pins.

- Standard dimensions: Spigot pins are typically manufactured with a diameter of 50 mm to fit seamlessly inside scaffold tubes with an outer diameter of 48.3 mm (approximately 50 mm). This dimensional compatibility ensures a secure and reliable connection. Most spigots are designed with square or star-shaped ends on both sides to firmly grip the inside of the tube and prevent slippage. At the center of the spigot, a collar or ring with a diameter of 50 mm and a thickness of 10 mm is incorporated to prevent direct tube-to-tube contact and to further enhance joint performance.

- Weight and quality: The weight of a scaffolding spigot pin is a strong indicator of the amount of material used and, consequently, its structural strength and durability. Market data shows significant variation in spigot weights. For example, some steel spigots weigh approximately 820 grams, while spigots from Iran Bast weigh around 600 grams. Kosar Metal spigots have been reported at both 500 and 700 grams in different references. These weight differences clearly reflect variations in material consumption and, consequently, potential product quality. Heavier spigot pins generally offer greater resistance to compression and tension, making weight a practical indicator of quality.

Such discrepancies in technical specifications represent a significant market challenge. A lack of transparency regarding exact weight and material composition can hinder informed decision-making for customers. Heavier products typically contain more material and therefore offer higher potential strength and durability. This provides a competitive advantage for manufacturers who emphasize safety and structural robustness, while lighter products often compete primarily on price.

The Role of Spigot Pins in Scaffold Load Capacity

Safety in construction projects depends on the strength of every individual scaffold component. In this regard, the scaffolding spigot pin plays an irreplaceable role. By evenly distributing axial loads along scaffold tubes, it prevents stress concentration at a single point, significantly enhancing overall system stability and safety.

One of the most critical technical parameters of a scaffolding spigot pin is its load-bearing capacity. According to various sources, a high-quality spigot pin can withstand loads of up to approximately 4,500 kg. This exceptional tensile capacity clearly distinguishes spigot pins from other scaffold fittings such as swivel couplers (typically rated at 1,000 kg) or double couplers (approximately 1,200 kg). This substantial load rating demonstrates that scaffolding spigot pins are specifically designed for ultra-heavy-duty projects and very tall structures, making them a key element in achieving maximum safety. As such, spigot pins are among the strongest scaffold connection components available.

Iranian National Standards in the Scaffolding Industry

The use of standardized spigot pins is essential for ensuring safety. In Iran, several national standards govern scaffolding systems, and compliance with these standards is mandatory for construction projects. Three key standards directly or indirectly related to scaffolding spigot pins include:

- National Standard 1-15443: This standard addresses general design and structural requirements for scaffolding systems, aiming to ensure strength and stability under various working conditions.

- National Standard 3454: This standard defines the technical specifications of scaffold tubes, including the standard diameter of 48 mm and wall thickness ranging from 2 to 3 mm. Since spigot pins must fit precisely inside these tubes, compliance with this standard is essential for compatibility.

- National Standard 10305: This standard focuses on the quality and strength of scaffold couplers. Adherence during spigot pin manufacturing ensures minimum safety requirements are met.

Compliance with these standards significantly reduces the risk of scaffold collapse and helps safeguard workforce health and safety.

Key Factors Affecting Scaffolding Spigot Pin Pricing

The price of scaffolding spigot pins is influenced by several key factors. Understanding these variables enables customers to make more informed purchasing decisions:

- Material quality and type: The use of high-quality steel or ductile cast iron, due to superior mechanical properties and manufacturing processes, generally results in higher product pricing compared to lower-grade materials.

- Size and dimensions: Product weight and dimensions are directly linked to raw material consumption and thus significantly affect final cost.

- Type of spigot pin: Spigot pins are available in various designs such as plain, locking, and threaded types. Locking and threaded variants, offering enhanced connection security, are typically more expensive than standard models.

- Market conditions and order volume: Global raw material price fluctuations and exchange rates have a direct impact on pricing. In addition, bulk orders usually benefit from discounted rates.

Key Considerations When Purchasing Scaffolding Spigot Pins

Selecting the right scaffolding spigot pin for a project is a strategic decision that directly affects safety and operational efficiency. When purchasing, the following factors should be carefully considered:

- Material quality: Given the critical importance of strength, it is essential to choose spigot pins made from ductile cast iron or high-quality steel capable of withstanding heavy loads.

- Weight and strength: Spigot pin weight can serve as a practical indicator of strength and durability. For heavy-duty applications, heavier products are generally recommended.

- Standards compliance: Ensure that the product complies with Iranian national standards, particularly Standards 1-15443 and 10305, which focus on general scaffold design and connection quality.

Conclusion and Zeman’s Competitive Advantage

In conclusion, traditional scaffolding spigot pins are far more than simple components; they represent a critical investment in the safety and stability of construction projects. Given their importance, selecting a high-quality product from a reputable and transparent supplier is essential.

Spigot pins supplied by Zeman are manufactured in accordance with the highest national standards and emphasize superior load-bearing capacity and premium raw materials, positioning them as a reliable and high-performance solution in the market.

In a highly competitive market where manufacturers focus either on price advantages or specific features, Zeman distinguishes itself through complete transparency in technical specifications and the provision of precise load capacity data—such as the impressive 4,500 kg rating. This commitment assures customers that they are investing in a product that elevates project safety to the highest possible level. Such dedication to quality and transparency makes Zeman a strategic partner for sensitive and high-rise construction projects, ensuring long-term value and confidence for its clients.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.