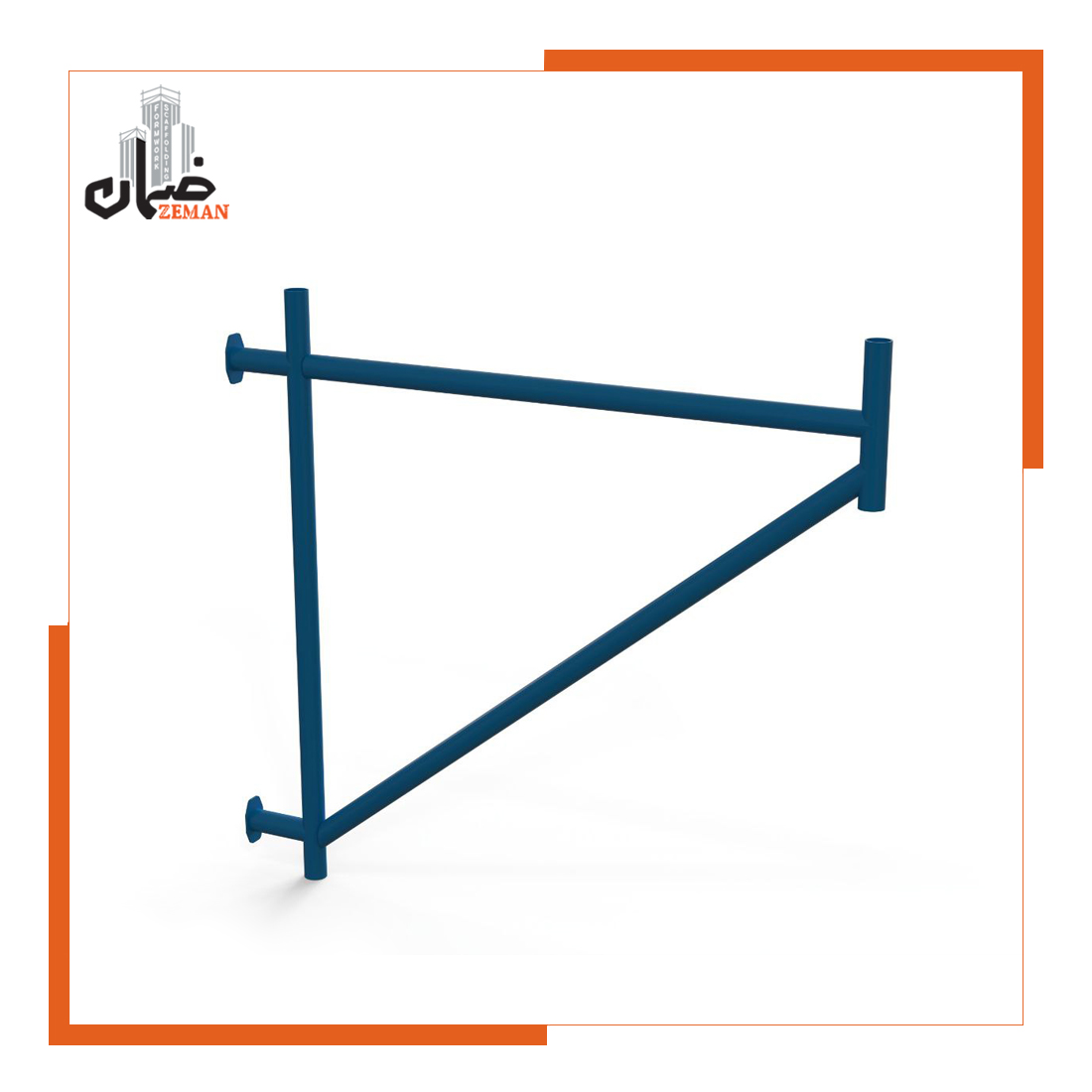

Cuplock Scaffolding Bracket

The Cuplock scaffolding cantilever bracket (console frame) is a specialized component of the Cuplock scaffolding system that projects horizontally outward from the main scaffold structure and is connected to the vertical standards by means of the Cuplock locking mechanism.

This component is specifically designed to extend the working platform beyond the main scaffold footprint without the need for any ground-based support.

Main Applications:

- Formwork execution at the edges of concrete slabs

- Creation of cantilever working platforms for plastering, bricklaying, or façade installation

- Supporting edge formwork of slabs in building construction projects

- Use in locations with limited ground access or restricted space beneath the working area (such as edges, gaps, or structural obstructions)

Installation Method: The cantilever frame is connected to the vertical scaffold tube at the required elevation by locking it in place using the lower and upper Cuplock nodes. A steel deck or scaffold plank is then installed on the frame, followed by the installation of guardrails and toe boards to prevent falls. Finally, the load-bearing capacity must be verified in accordance with the project’s structural and execution drawings.

Cuplock Scaffolding Bracket

Introduction – A Transformation in Concrete Formwork and Scaffolding Systems

The construction industry has always sought solutions to increase speed, enhance safety, and reduce costs in civil engineering projects. In this context, formwork and scaffolding serve as two fundamental pillars of any construction project and play a critical role. With a deep understanding of these needs, Zeman Company has positioned itself as a leading manufacturer of concrete formwork equipment, including cantilever brackets, also known as Cuplock scaffolding brackets. The company’s commitment to innovation and quality has resulted in products that not only meet high technical standards but also enable contractors and engineers to execute their projects with greater efficiency and confidence.

Modern construction projects—especially high-rise and complex structures—present challenges that traditional methods can no longer adequately address. These projects require support and formwork systems capable of bearing heavy loads while allowing fast and easy installation and dismantling. In this regard, cantilever brackets represent a key solution, offering an intelligent response to these challenges. The use of these tools transforms construction processes and contributes significantly to ensuring quality, precision, and safety at the highest level.

Understanding the Fundamentals – Cantilever Brackets

In the specialized environment of the construction industry, technical terminology plays a vital role in communication and project planning. A clear and thorough understanding of cantilever brackets is essential for making optimal decisions on any project.

A cantilever bracket is a critical component in concrete formwork systems and functions as a strong and temporary working platform. Its primary application is in concreting tall walls and high-rise structures where construction is carried out in multiple stages. The main function of the bracket is to create a safe and stable support for holding formwork at height, while also providing a secure working platform for laborers. This system allows precise plumbing and alignment of formwork and facilitates the installation of guardrails and suspended scaffolding.

Cantilever brackets are generally manufactured in two types—tubular and profile-based—and are typically designed in L-shaped or triangular configurations. The key components of this system include the bracket body, inner tie rod, cone, wing nut (cam nut), and outer tie rod, all of which ensure a secure anchorage to the previously poured concrete wall.

Strategic Advantages – Why Choosing Cantilever Brackets Is a Smart Decision

The use of cantilever brackets goes beyond a purely technical choice and represents an economic and safety strategy for project optimization. The advantages of these systems operate synergistically and have a significant impact on overall project efficiency.

Exceptional Speed and Efficiency

Cantilever brackets, thanks to their easy installation mechanism, allow rapid progress in multi-stage concreting operations. This high execution speed leads directly to a reduction in the overall project timeline.

Maximum Safety and Structural Stability

Safety is the highest priority in construction projects. Cantilever brackets provide a secure and stable working platform that protects workers from falls while ensuring the stability of formwork against fresh concrete pressure and adverse weather conditions.

Sustainable Cost Efficiency

Choosing this system is not merely a tactical decision to reduce costs, but a comprehensive financial strategy. Fast installation directly results in significantly lower labor costs and reduced equipment rental time. Furthermore, due to their engineered design and steel construction, these systems are capable of bearing heavy loads despite their relatively low weight. The reusability of components across multiple projects—thanks to high durability and corrosion resistance—constitutes a long-term investment. Ultimately, these combined advantages sustainably and substantially optimize the overall project budget.

Technical Specifications and Manufacturing Standards

By adhering to the highest manufacturing standards, Zeman delivers products that are technically reliable and safe. Understanding the detailed technical specifications enables engineers and contractors to make informed decisions with complete confidence.

Technical Specifications of Zeman Cantilever Brackets

| Feature | Specification |

|---|---|

| Standard Dimensions | 90 × 120, 100 × 120, 120 × 120, and 160 × 120 cm |

| Approximate Weight | 24–45 kg (depending on dimensions and profile type) |

| Main Body Material | High-quality structural steel (e.g., Mobarakeh Steel) |

| Accessory Material | Ductile cast iron for components such as cones and wing nuts |

| Type | Profile-based (more commonly used due to ease of installation) and tubular |

Installation Guide and Safety Protocols

Correct and safe execution complements manufacturing quality. The following guidelines help contractors fully benefit from Zeman cantilever brackets.

Pre-Installation Preparation

Before commencing installation, the working surface must be carefully inspected. The ground must be firm and stable; if the soil is soft, steel base plates should be used to create a secure foundation. All components must be checked for integrity and quality prior to installation.

Cantilever Bracket Installation Procedure

The installation of cantilever brackets is an engineered process consisting of the following steps:

- Design and Planning: Precise determination of installation locations and calculation of applied loads.

- Installation of Inner Tie Rod and Cone: These components are embedded in the wall during the first concreting stage.

- Bracket Installation: In the following stage, the bracket body is installed onto the outer tie rod and wing nut to form the working platform.

- Formwork and Bracing: Formwork panels are placed on the bracket and properly braced to ensure structural stability.

- Concrete Pouring: Once formwork and bracing are completed, concreting is carried out.

- Dismantling and Repetition: After the concrete has cured, the bracket is easily removed and reinstalled at the next elevation.

Critical Safety Checklist and Best Practices

Using safe equipment is only one part of the process; strict adherence to safety protocols is essential. This includes:

- Personal Safety: Mandatory use of safety helmets, gloves, anti-slip footwear, and safety harnesses for all workers.

- Environmental Conditions: Suspension of work during adverse weather conditions such as strong winds, storms, or heavy rainfall.

- Continuous Inspection: All clamps and connections must be inspected and tightened before each work shift and after severe weather events.

Frequently Asked Questions About Cuplock Scaffolding Brackets

This section addresses the most common questions raised by clients and contractors regarding cantilever brackets, helping you make a confident and efficient choice for your project.

Why is using cantilever brackets more economical than traditional methods?

High installation speed and ease of execution significantly reduce labor and equipment rental costs. Additionally, high durability and reusability of components lower expenses in future projects.

What are the most important safety considerations when using this equipment?

Use of personal protective equipment and avoiding work under unfavorable weather conditions are among the most critical safety measures.

What are the standard dimensions of formwork brackets?

Formwork brackets are commonly manufactured in dimensions of 90, 100, 120, and 160 cm by 120 cm.

Conclusion and Call to Action

In today’s construction environment, selecting the right tools makes a decisive difference in project success and profitability. Cantilever brackets, as modern and proven solutions, offer exceptional speed, the highest level of safety, and sustainable cost efficiency for your projects.

Zeman is not only a manufacturer of high-quality equipment but also a trusted consultant and partner by your side. Our expert team is ready to provide professional technical advice and assist you in selecting the most suitable system for the specific requirements of your project. For more information, free technical consultation, or order placement, please contact us.

Get expert advice

Our sales experts at Zaman are ready to provide guidance and advice before your purchase.

Reviews

There are no reviews yet.