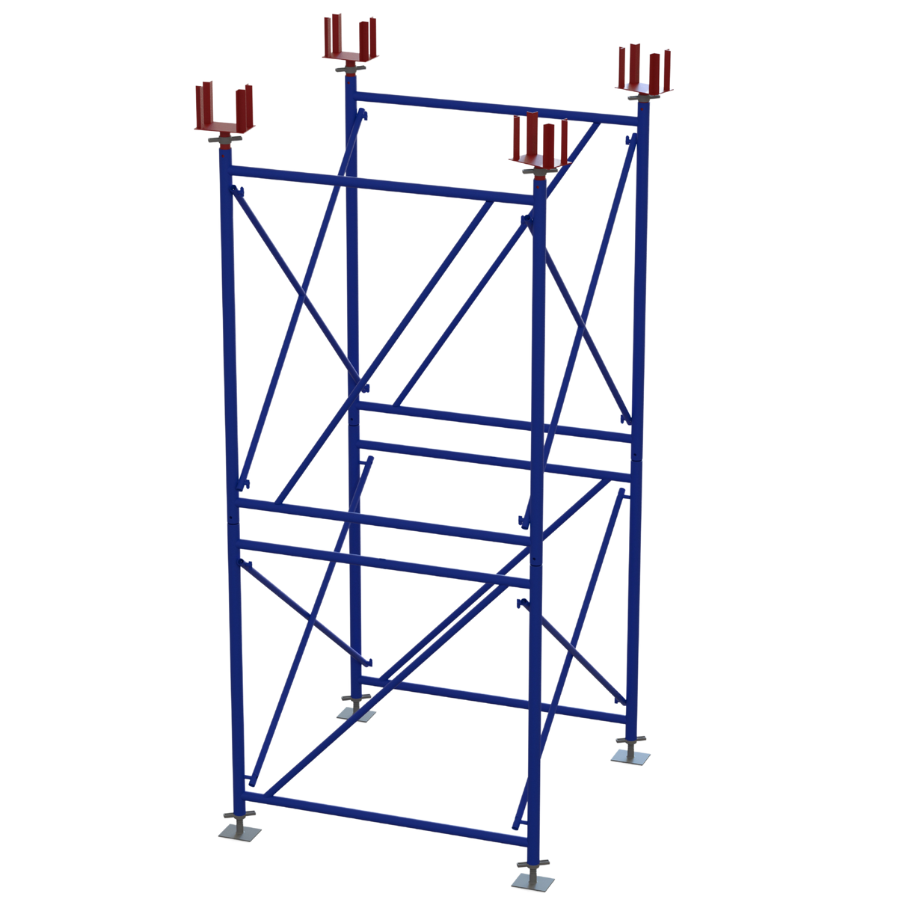

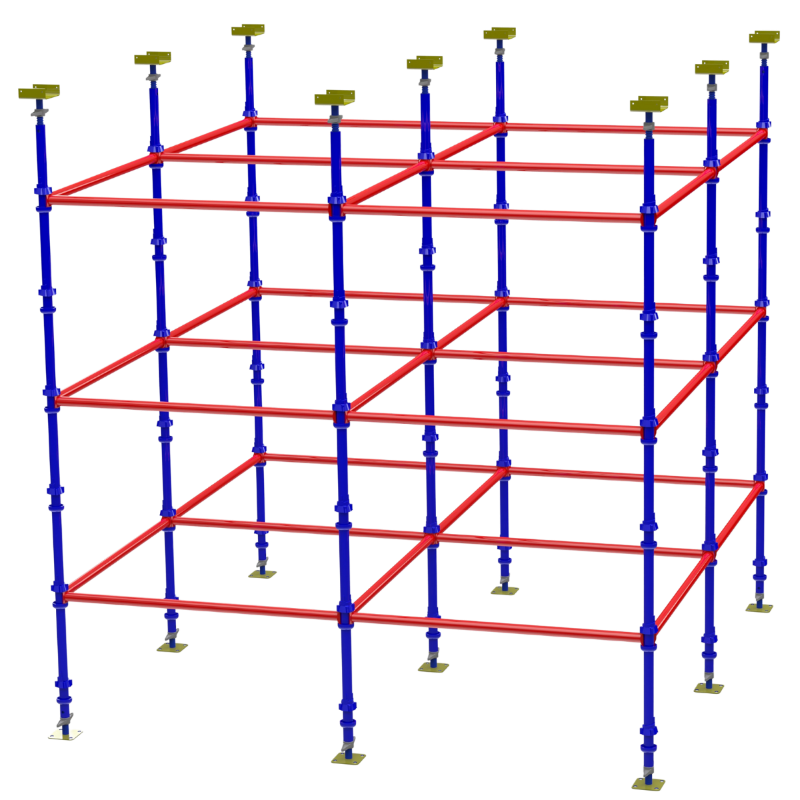

H‑Frame Scaffolding

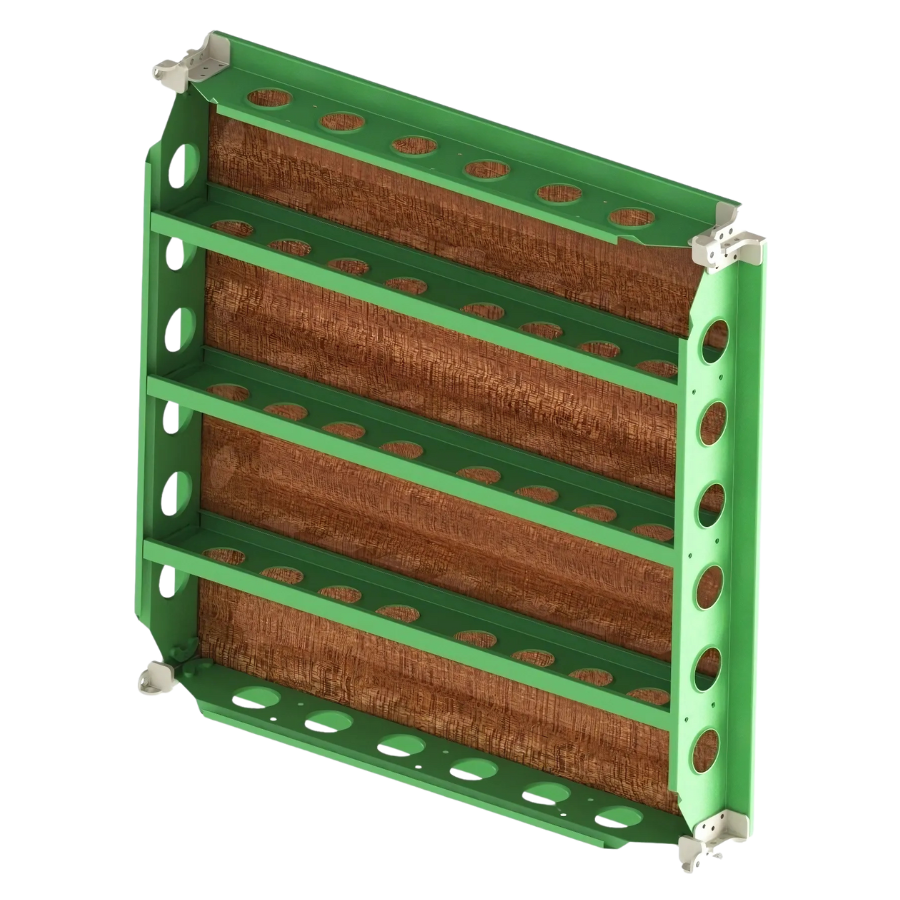

ECO Slab Formwork

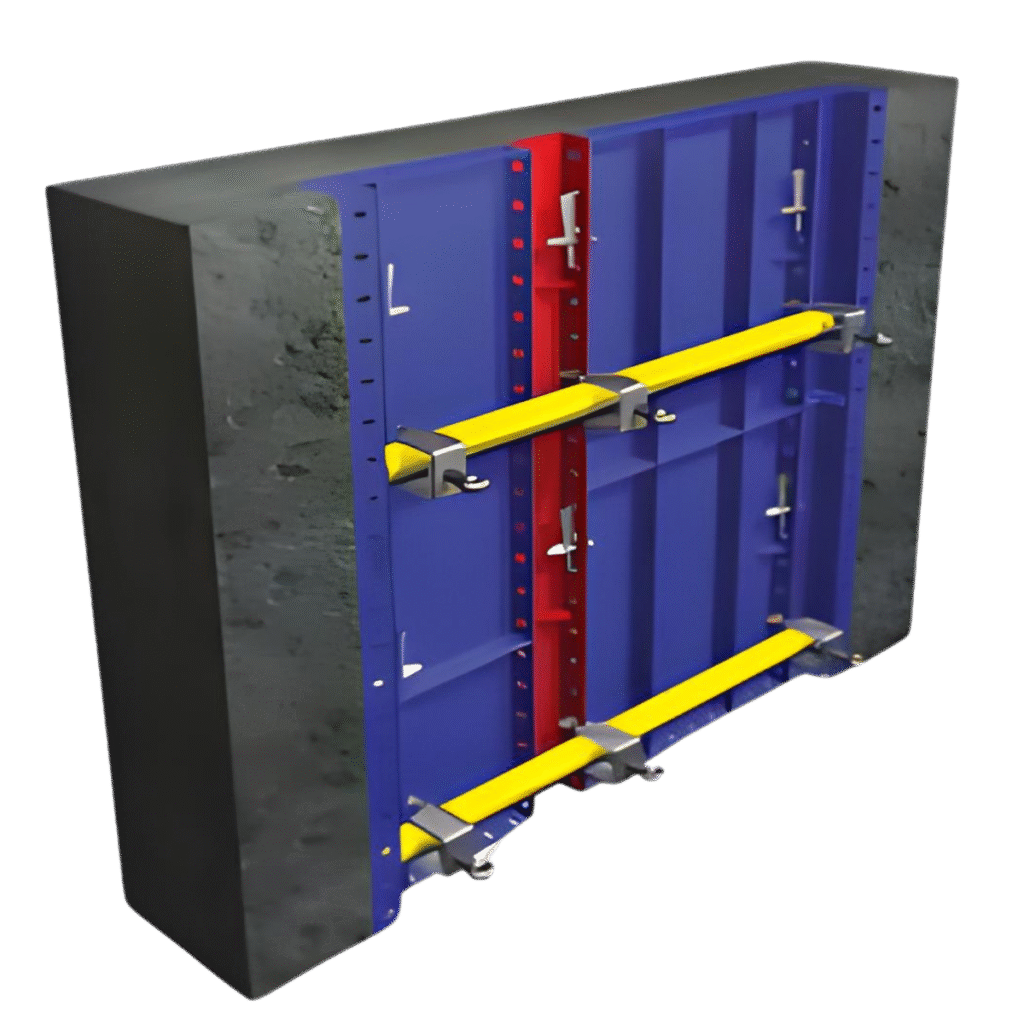

Concrete Formwork Systems

Cuplock Scaffolding

Selected Projects

Execution of over 100 projects in the field of concrete formwork and scaffolding systems implementation.

About Us

Zeman Company is a leading manufacturer of concrete formwork systems and metal scaffolding equipment in the Middle East and Central Asian countries. The founder of Zeman, Mr. Haj Hossein Mortazavi Sharif, has over 35 years of experience in the manufacturing and industrial sectors. He began his professional activity in 1992 in the field of producing concrete formwork equipment and metal scaffolding systems.

At Zeman Company, we take pride in working with a young, highly skilled, and creative team, alongside advanced machinery and state-of-the-art equipment, enabling us to take significant steps toward continuous growth and development in the manufacturing of a complete range of concrete formwork and metal scaffolding products.

In response to the diverse requirements of our clients, we are capable of designing and supplying a wide range of formwork and scaffolding systems. Our production team, backed by more than three decades of experience, maintains the highest standards of quality at every stage of the manufacturing process.

Each production unit is supervised by a dedicated foreman who monitors and manages the daily operations of the workforce. Advanced machinery and automated robotic welding technology are extensively utilized, increasing our scaffolding production capacity to over 10 tons per day.

Furthermore, our concrete formwork systems are manufactured using mechanized equipment specifically designed and built by Zeman’s engineering team. This proprietary machinery has increased our concrete formwork production capacity to approximately 20 tons per day.

Manufacturer of Various Modular Formworks

Pressed (Bent-Edge) Metal Formwork, Welded (Strip-Type) Metal Formwork, and Plywood Frame Formwork.

Manufacture of all formwork accessories and fittings.

Types of soldiers, various types of pins and wedges, clamps, bolts, different types of double-tube washers, wing nuts, and other related items.

Mass production of jacks.

Mass production of support jacks, cross jacks, plain jacks, T‑head jacks, plumb adjustment jacks, and other related types.

Manufacture of various types of scaffolding systems.

Manufacture of various types of modular scaffolding systems, including Cuplock scaffolding, triangular scaffolding, and ringlock scaffolding.

Design and manufacture of various types of special formwork systems.

Design and manufacture of various types of special concrete formwork in accordance with the needs of industry professionals and valued customers.

Commercial services for formwork plywood.

Import and supply of various types of formwork boards, including three-ply panels, squared lumber, wooden beams, and other related products.

Latest Articles

Comprehensive Guide to Purchasing Metal Corner Formwork – Critical Connections for Structural Integrity

In the world of modern construction and concrete projects, precision and quality are of paramount importance. When it comes to

Causes of Concrete Formwork Deformation and Methods for Preventing It

In the construction industry, the final quality of a concrete structure is directly dependent on the quality of its formwork

Used or New Concrete Formwork? A Comprehensive Guide to Cost‑Effective Selection for Construction Projects

In today’s highly volatile construction industry, cost management is no longer an “option,” but a vital “necessity” for the survival

Types of Concrete Wall Formwork | Professional Execution of Concrete Wall Formwork

Why Is Concrete Wall Formwork Critically Important? Concrete walls are among the most fundamental components of civil engineering and construction