Concrete Slab Ceiling | A Comprehensive Guide to Design-Execution-and Benefits

Concrete Slab Ceiling | Comprehensive Guide to Design, Execution, and Benefits

Concrete slab ceilings, as one of the most fundamental and common structural elements in the construction industry, play a pivotal role in transferring vertical and lateral loads. These reinforced concrete plates, whose thickness is negligible compared to their length and width, have become a popular choice among engineers and builders due to their high rigidity, long durability, and excellent performance against seismic forces. The application of concrete slabs extends beyond floors and ceilings of buildings, encompassing a wide range of infrastructure projects such as foundations, bridges, tunnels, and even road pavements.

This comprehensive report aims to provide a technical and practical guide by thoroughly and multidimensionally examining concrete slab ceilings. Along the way, it introduces various types of slabs based on function, shape, and construction method, reviews fundamental design principles, step-by-step construction stages, and includes analytical comparisons with other common roofing systems to provide a complete picture of the advantages and limitations of each system.

Classification and Types of Concrete Slabs

Understanding the different types of concrete slabs based on various criteria is the first step in making the optimal choice for any project. These slabs can be primarily categorized based on structural performance, shape and geometry, as well as construction method.

Classification Based on Structural Performance: One-Way and Two-Way

The slab’s behavior under applied loads forms the basis of this classification, which depends on the ratio of the longer span to the shorter span.

One-Way Slab

In one-way slabs, load transfer mainly occurs in one direction. This type of slab is designed when the ratio of the longer span to the shorter span is equal to or greater than 2. In other words, the slab is supported only on two opposite edges and transfers forces to beams parallel to the main direction (usually the shorter span). Therefore, the main reinforcement bars to resist bending moments are embedded only in this direction. Additionally, thermal and shrinkage reinforcement bars are placed perpendicular to the main rebars to prevent cracking caused by shrinkage and temperature variations in the concrete. Joist block ceilings are a typical example of one-way slabs.

Two-Way Slab

Two-way slabs transfer loads in four directions, and their deformation under load assumes a spherical shape. This slab type is designed for spaces where the ratio of the longer span to the shorter span is less than 2 and it is supported on all four sides by beams or columns. To resist bending moments in both directions, two perpendicular layers of reinforcement bars are required. This characteristic enhances the slab’s strength and rigidity, making it suitable for longer spans and heavier loads.

Classification Based on Shape and Geometry

This classification refers to the final shape of the slab after execution, each optimized for specific applications and conditions.

Flat Slab

The flat slab is one of the most widely used types of concrete slabs that rests directly on the columns without beams. This system is highly suitable for high-rise buildings, parking lots, and warehouses that require open spaces free from beams. However, due to the elimination of beams, shear stresses and negative moments around the slab-column joint increase significantly, a phenomenon known as “punching shear.” To counter this effect, three main methods are used:

- Simple Flat Slab: This method is used for short spans and light loading and is easier to construct than beam-and-slab systems.

- Mushroom Flat Slab (with column head): In this method, the thickness of the column section near the slab is increased to control punching shear resistance.

- Flat Slab with Drop Panel: Here, slab thickness around the column is increased, which besides controlling punching shear, also enhances the slab’s bending resistance. This method is more commonly used in Iran due to easier execution compared to the column head method.

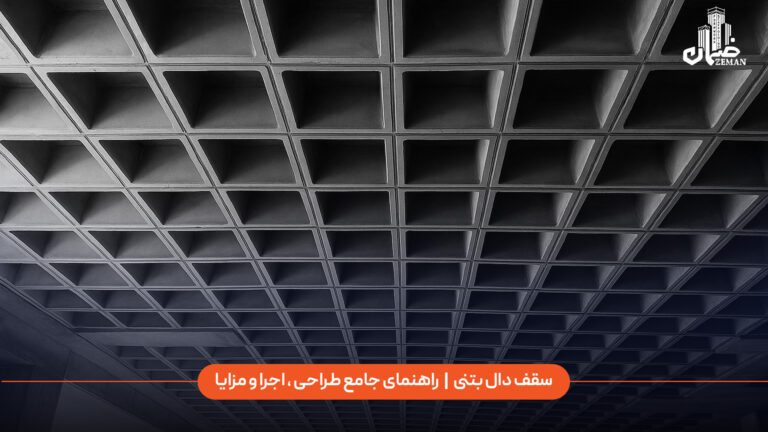

Waffle Slab

The waffle or ribbed slab is a type of two-way slab where the underside features a hollow grid (square or triangular pattern). This hollow grid, giving the ceiling a visually appealing honeycomb appearance, reduces the overall structural weight by eliminating ineffective concrete. Due to its high strength, excellent load capacity, and ability to cover very long spans (over 12 meters), waffle slabs are ideal for public buildings such as airports, hospitals, and commercial complexes.

Hollow Core Slab

The hollow core slab, also known as a voided slab, is a modern concrete flooring system incorporating internal voids or hollow elements. The primary goal of this design is to reduce slab weight without compromising its flexural strength. By removing ineffective concrete in the central zone, this system reduces the dead load on the structure. Common types of hollow core slabs include U-Boot and Cobiax systems, which use plastic or polypropylene molds to create voids within the slab. These systems enable covering large spans and decreasing the number of supporting columns.

Classification Based on Construction Method

Concrete slabs can be constructed either on-site (cast-in-place) or as precast components.

Cast-in-Place Slab

In this method, all phases of slab construction including formwork, reinforcement placement, and concrete pouring are performed at the project site. This approach is more economical for smaller projects and allows for complex and diverse geometric shapes. Additionally, cast-in-place slabs exhibit higher resistance against dynamic loads.

Precast Slab

Precast slab components are produced in well-equipped factories under strict quality control and then transported to the project site. This method offers very high construction speed, and due to fabrication in a controlled environment, the concrete quality is superior and unaffected by weather conditions. Precast slabs are cost-effective for large-scale projects and require less skilled labor.

Fundamental Principles of Structural Design for Concrete Slabs

Designing a concrete slab ceiling is a complex and precise process that requires a thorough understanding of applied loads, adherence to engineering considerations, and compliance with regulatory standards.

Loads Applied to the Slab

Two main types of load act on any structure and must be carefully considered in slab design:

- Dead Load: These loads are constant and predictable, including the weight of the slab itself, beams, fixed walls, and permanent building equipment. In design software, the concrete slab weight is automatically calculated and applied as a uniform surface load.

- Live Load: These loads are variable and include the weight of people, furniture, and movable equipment. Proper understanding and design for both load types are essential to ensure structural safety and stability.

Key Design Considerations

In addition to controlling applied loads, structural designers must consider other critical factors:

- Punching Shear Control: In flat slabs where slab loads transfer directly to columns, shear stresses around the column region sharply increase. To prevent column punching failure, methods such as column heads or drop panels are employed.

- Deflection Control: Deflection or bending of the slab under load is a key design criterion. In flat slabs with beams, secondary beams help reduce deflection significantly at mid-span and allow for the use of thinner slabs.

Regulatory Codes in Iran

The design and construction of concrete structures in Iran are governed by the National Building Regulations and seismic design standards.

- National Building Regulations – Chapter 9: This chapter is the main reference for designing and constructing reinforced concrete buildings and provides detailed rules for all structural components including slabs. These rules specify minimum clear spacing of reinforcement bars in slabs, which must be no less than 25 mm or the largest bar diameter.

- Standard 2800: This code addresses seismic design. According to Chapter 9 and Standard 2800, using slab-column systems as intermediate moment-resisting frames is only permitted under very stringent conditions, which include:

- A maximum of 3 stories or 10 meters height.

- The structure must not be located in areas with very high seismicity (design acceleration less than 0.35g).

- The importance factor of the structure should not be very high.

These regulatory limitations are a critical factor in choosing roofing systems in earthquake-prone regions of Iran. While flat slabs offer architectural advantages by eliminating beams and creating open spaces, their poor diaphragm behavior and vulnerability to punching shear under lateral loads compel engineers to compensate by using more shear walls. This increases project cost and complexity, turning an apparent architectural benefit into a technical and economic challenge. This compromise between architectural goals (open space) and engineering requirements (seismic resistance) is one of the key decisions in the design process.

Step-by-Step Guide to Concrete Slab Execution

Proper execution of concrete slabs requires precision and high skill in four primary stages. Any mistake in this process can directly affect structural safety and durability.

Step One: Formwork and Substructure

This stage is considered the most sensitive and critical part of concrete slab execution. Formwork provides a temporary framework to hold the fresh concrete until it attains sufficient strength.

- Site Preparation: Initially, the slab construction area must be cleared of all debris, waste, or vegetation, and if necessary, a thin concrete layer is poured as a base.

- Formwork and Substructure Selection: Formwork is typically made of wood, plastic, or metal. Metal formwork, due to its higher strength and precision, is preferred for high-quality projects. Temporary supports and shoring are required to bear the weight of concrete, reinforcement, and formwork. Additionally, the formwork’s interior surface is coated with oil or diesel to facilitate easy removal after concrete sets.

Step Two: Reinforcement Placement

Concrete is weak in tension; therefore, steel reinforcement bars are used to compensate for this weakness and provide tensile strength in the slab.

- Types of Rebar: Bending rebars carry main loads while thermal and shrinkage rebars prevent cracking caused by temperature and moisture variations in the concrete. Thermal rebars are especially recommended in joist block ceilings to minimize concrete cracking.

- Execution Requirements: Reinforcement in one-way and two-way slabs differs and must comply with Chapter 9 of the National Building Regulations. Rebars should be interconnected in a mesh pattern to maximize slab strength and durability.

Step Three: Concrete Pouring and Final Finishing

This stage involves casting and leveling concrete within the formwork.

- Concrete Placement: Concrete must be poured continuously and rapidly to prevent segregation and the formation of air pockets. Semi-stiff concrete is not recommended because fresh concrete must fully penetrate the spaces between reinforcement bars. The use of a vibrator is essential to ensure full compaction and remove air voids.

- Surface Finishing: After pouring, the concrete surface should be smoothed and leveled using tools such as screeds and trowels. This not only improves appearance but also aids uniform load distribution throughout the slab.

Step Four: Curing and Formwork Removal

This final stage ensures the concrete slab achieves its ultimate strength.

- Curing: Concrete curing is the process of maintaining the concrete’s moisture content for a specified period after pouring. This is vital for the completion of cement’s chemical reactions and achieving the concrete’s maximum desired strength and durability.

- Formwork Stripping: Removing the shoring and formwork beneath the slab is the final stage that must be performed carefully and in accordance with National Building Regulations. Rushing this stage, especially in unfavorable weather conditions, can cause increased slab deflection and potential concrete cracking. This highlights that success in a construction project is not limited to precise design calculations, but also depends on a deep understanding and strict adherence to the concrete’s physical and execution processes. A simple decision to expedite work can lead to serious and hidden consequences for the structure’s durability and safety.

Advantages, Disadvantages, and Applications of Concrete Slab Ceilings

Concrete slabs, like any other construction system, have a set of strengths and weaknesses, the analysis of which is essential for informed decision-making.

General Advantages of Concrete Slab Ceilings

- High Strength and Durability: Concrete slabs have considerable resistance to bending and shear loads, and due to the nature of their materials, they offer a long lifespan and high durability.

- Fire Resistance: Concrete is an inherently fire-resistant material. The main composition of concrete (cement and aggregates) has very low thermal conductivity and transfers heat slowly. This characteristic allows concrete to act as a protective shield against fire and prevent its spread.

- Sound and Thermal Insulation: Due to their high mass and density, concrete slabs serve as excellent sound and thermal insulators. This feature causes heat to pass slowly through the ceiling and also absorbs and dampens sound waves. This insulation performance is a major functional benefit derived from the system’s high weight.

General Disadvantages and Considerations

- High Weight: One of the most significant drawbacks of concrete slabs is their high weight, which increases the dead load of the structure and may necessitate stronger foundations and higher costs.

- Low Tensile Strength: Concrete itself performs poorly against tensile forces, a deficiency that is compensated for by the use of steel reinforcement.

Common Applications of Concrete Slab Ceilings

Concrete slabs are used in a variety of applications due to their strength and flexibility:

- Industrial and Commercial Buildings: In parking lots, warehouses, and high-rise buildings due to their ability to withstand heavy and concentrated loads.

- Civil Projects: In the construction of bridge decks, tunnels, and dams, requiring durability and resistance to heavy loads and environmental conditions.

- Modern Applications: Voided slabs, such as U-Boot, have also found application in healthcare and educational buildings due to the possibility of eliminating central columns.

An important point in the economics of construction projects is the scale of the work. While cast-in-place concrete slabs might be considered an expensive option for small projects due to formwork and labor costs, the same systems (especially precast or lightweight types like waffle) are highly cost-effective in large projects due to material savings and high speed. This shows that selecting a roofing system is not only a technical decision but also an economic analysis based on the project’s scale.

Comparative Analysis with Other Roofing Systems

The choice of a concrete slab is often made in competition with other common roofing systems. Understanding the key differences of each system aids in informed decision-making.

Concrete Slab vs. Joist Block Ceiling

The main difference between these two systems lies in their execution method and level of integration.

- Concrete Slab Advantages: Concrete slabs are executed monolithically, offering higher resistance to fire, earthquakes, and pressure, and providing a longer service life.

- Joist Block Advantages: These ceilings impose a lower dead load on the structure due to the use of lightweight blocks, such as polystyrene (EPS). Furthermore, their execution is simpler and faster than concrete slabs and they generally cost less. These features make the joist block system a common option for small residential projects.

Concrete Slab vs. Steel Deck Ceiling

Execution speed is the primary distinguishing feature of the steel deck ceiling.

- Steel Deck Advantages: These ceilings are executed up to 11 times faster than concrete slabs. Their weight is drastically reduced due to the use of steel sheets, and the need for shoring is often eliminated. The embossments and ribs on composite steel deck sheets create better adhesion with the concrete, increasing the system’s resistance to shear stresses.

- Technical Consideration: Non-composite steel deck ceilings lack these ribs and do not have monolithic behavior with the concrete, thus requiring more tensile reinforcement, which prolongs execution time.

Comparison of Voided Slab Types

Voided slab systems themselves have important differences:

- Waffle vs. U-Boot and Cobiax: Waffle slabs, by utilizing temporary and reusable forms, typically have lower execution costs and time compared to U-Boot and Cobiax.

- Seismic Performance: Compared to Cobiax, the Waffle slab exhibits more favorable seismic performance. This advantage, coupled with the reusability of its forms, makes Waffle an economic and safe option in earthquake-prone areas.

| Criterion | Conventional Concrete Slab | Joist Block Ceiling | Steel Deck Ceiling | Waffle Slab Ceiling |

|---|---|---|---|---|

| Execution Speed | Medium | Fast | Very Fast (up to 12 times) | Fast |

| Slab Weight (Dead Load) | High | Medium (due to blocks) | Very Low | Low |

| Maximum Span | Short to Medium | 8 meters (up to 12m with double joist) | 3 to 5 meters (without shoring) | Long (over 12 meters) |

| Seismic Resistance | High | Medium | Very High (due to low weight) | Very High |

| Execution Cost | Medium to High | Low | Medium | Medium to Low |

Practical Examples in Iranian Projects

The use of concrete slab systems in major Iranian projects demonstrates the engineering community’s confidence in these technologies.

- Waffle Slab Projects: Notable examples of waffle slab usage include large-scale projects in Tehran. The Homeland Ardastani residential project, with a built-up area of over 27,000 square meters and 22 floors, used waffle forms to reduce structural weight and achieve a modern design. Similarly, the Dorous Street project is a 9-story residential building with a longest span of 12 meters that utilized this system.

- U-Boot Projects: After entering Iran, U-Boot systems received technical approval from the Building and Housing Research Center, which facilitated their widespread adoption in the construction industry. Due to their ability to eliminate intermediate columns and create long spans up to 18 meters, these ceilings have found extensive use in industrial centers and parking lots.

The Importance of Supporting Equipment and Execution Entities in Concrete Slab Construction

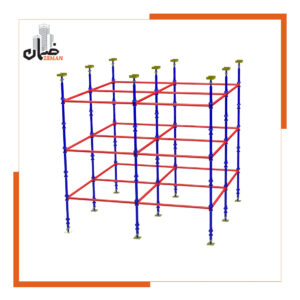

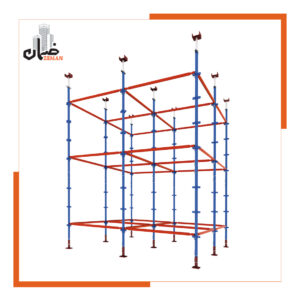

The success of concrete slab execution, besides accurate design, relies entirely on the quality and efficiency of supporting equipment and execution entities. This equipment creates the temporary structure that holds the concrete in place until it achieves sufficient strength and ensures worker safety. One of the most crucial pieces of equipment is the supporting system, such as shoring jacks and scaffolding.

The simple ceiling jack is one of the most widely used tools for supporting formwork and concrete slabs during execution. These jacks must remain in place until the concrete achieves sufficient strength (usually 7 days for pre-stressed concrete).

For large projects and high elevations, the use of more advanced and powerful jacks is necessary. Purchasing a U-Head Ceiling Jack or U Jack provides access to jacks with high load-bearing capacity and precise adjustability, which are essential for supporting heavy and extensive slabs.

For supporting vertical elements like walls and columns, the Wall and Column Support Jack plays a key role. These jacks prevent formwork deformation during concrete pouring and ensure dimensional accuracy.

Furthermore, for professional execution, purchasing the Plumb Alignment Jack to ensure columns and walls are vertical, and the Wall Back Support Jack to brace walls across their height, are crucial.

Scaffolding systems are also essential for creating safe platforms for workers and for transporting materials at height. There are various types of scaffolding, each with its own advantages and disadvantages. Traditional scaffolding is cheap but requires time-consuming installation and dismantling, and a large labor force.

In contrast, more advanced systems such as Cup Lock Scaffolding, Cup Lock Scaffolding (Cup Type), Hammerhead/Rosette Scaffolding, and H-Frame Scaffolding dramatically increase erection and dismantling speed and offer higher safety.

For large and high-rise projects, Triangular Omega Scaffolding and Triangular Shoring are highly suitable options due to their superior strength and excellent stability.

Service Scaffolding is also designed for accessing specific parts of the building.

For executing these complex systems, accurate cost calculation is essential, and the price of Cup Lock Scaffolding and Scaffold Price and Purchase are crucial factors in project budgeting. Also, to protect the ground surface and create a firm base, purchasing and knowing the price of scaffolding base boards is necessary.

Execution entities are also highly important. The quality of the formwork directly affects the appearance and surface quality of the concrete. Purchasing high-quality Formwork Plywood allows for the creation of a smooth and flawless surface.

Modular formwork systems, such as Modular Metal Formwork and Modular Formwork Systems, reduce long-term costs due to their reusability and high durability.

For specific projects, using Tunnel Formwork for monolithic execution of walls and ceilings, or Foundation Formwork for executing bases, is necessary.

For fast and professional execution, ECO Ceiling Formwork and Concrete Wall Formwork are among the efficient solutions.

For complex components, ZEMAX Variable Column Formwork and Precast Concrete Parts Formwork enable precise and rapid execution.

ZEMAX Variable Column Formwork

Precast Concrete Parts Formwork

This analysis shows that selecting the appropriate equipment and execution bodies is not an expense, but a strategic investment that determines the quality, safety, and productivity of the entire concrete slab construction project. Utilizing specialized products and services, such as those offered by Zeman Company, is the key to success in complex and large-scale projects.

Conclusion: Smart Selection for the Future of Construction

The concrete slab ceiling, as a structural system with numerous technical advantages, including strength, durability, and insulation, is considered a reliable and sustainable solution in the construction industry. However, as examined, optimal slab selection requires a comprehensive analysis that strikes the right balance between technical, economic, and architectural considerations.

Key Recommendations for Selecting a Ceiling System:

For short spans and light loads in small and residential projects, joist block ceilings or simple flat slabs are acceptable options due to their ease of execution and reasonable cost.

For longer spans and heavy loads in large industrial and commercial projects, more advanced systems such as Waffle Slabs or Voided Slabs (U-Boot/Cobiax) are recommended. These systems enable larger spans and more flexible architecture by reducing weight and saving materials.

When execution speed is the main priority of a project, the Steel Deck ceiling is an unbeatable option due to its significant reduction in time and weight.

Ultimately, the success of a construction project does not solely depend on technical design knowledge but also on a deep understanding of execution details, strict adherence to regulatory standards, and the intelligent selection of structural systems based on real needs and project scale. This comprehensive analysis helps project managers and engineers make informed decisions that lead to the construction of safe, durable, and economically optimized structures.